Zongheng3D specializes in manufacturing high-precision industrial SLA, DLP, and SLS 3D printers, along with advanced photopolymer resins and engineered powders (PA11, PA12, TPU, Nylon-GF). Our systems deliver micron-level accuracy, high-speed production, and 24/7 reliability for aerospace, automotive, medical, and manufacturing applications. We also provide custom 3D printing solutions—tailoring machines, materials, and workflows to meet specialized requirements. From rapid prototyping to end-use part production, Zongheng3D empowers industries with cutting-edge additive manufacturing technology.

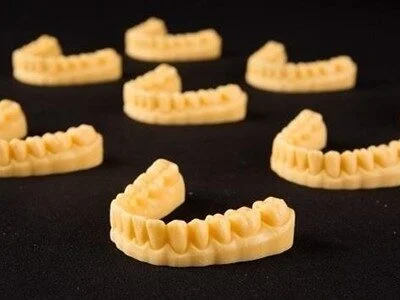

Engineered for complex geometries with ±0.1mm accuracy. Ideal for dental, jewelry, and microfluidic applications. Features dual-laser scanning at between 6000-10000mm/s for rapid production.

Mass-produce detailed prototypes with 4K resolution (50μm-100μm XY). Self-developed top-down system enables large-format printing (up to 384mm) with minimal supports.

Industrial laser (100W) sinters PA11/12, TPU, and GF-Nylon into durable components. Integrated powder handling reduces labor by 90%

Offers high-performance materials including PA11, PA12, TPU, Nylon-GF, and specialty resins—optimized for SLS, SLA, and DLP technologies for prototyping and production.

Delivering micron-level accuracy ±0.1 across six models from compact SLA300 to large-format SLA1200 to match any production need. Engineered with high-speed galvanometers (up to 6000mm/s) and temperature-controlled vats. Perfect for dental labs, investment casting, and functional prototypes. Custom configurations available.

Featuring DM200, DM300, and DM400 models—delivers 4K ultra-HD resolution (50μm-100μm precision) and top-down projection technology for flawless surface finishes and minimal support structures. Designed for dental labs, jewelry casting, and rapid prototyping, these printers combine batch production efficiency with large build volumes (up to 400mm)

including the SLS2030 (entry-level) and SLS3540 Pro (production-grade) models—delivers high-speed, high-efficiency selective laser sintering for functional prototypes and end-use parts. Engineered with industrial 50W fiber lasers and precision temperature control (±0.5°C), these printers support PA11, PA12, TPU, and Nylon-GF materials with excellent mechanical properties and 95%+ powder reuse rates.