Revolutionizing Manufacturing with Industrial SLA 3D Printing

Discover how cutting-edge SLA technology is transforming production processes, reducing costs, and unleashing creativity in modern manufacturing. Explore our case study to see the future of industrial fabrication.

Industrial light-cured Stereolithography (SLA) 3D printing is an advanced additive manufacturing technology that uses ultraviolet (UV) light to cure and solidify liquid photopolymer resin layer by layer, creating highly detailed and precise 3D objects.

Break free from traditional manufacturing constraints. With industrial light-cured SLA 3D printing, your most complex designs come to life with unparalleled precision and detail.

Time is money in manufacturing. See how our clients have slashed prototyping times by 75% and brought products to market faster than ever before.

Small batch runs no longer mean big expenses. Learn how companies are saving up to 50% on low-volume production costs with SLA technology.

Reduce waste, lower energy consumption, and minimize your carbon footprint. Discover how SLA 3D printing is paving the way for greener manufacturing practices.

SLA 3D Printing

SLA 3D Printing

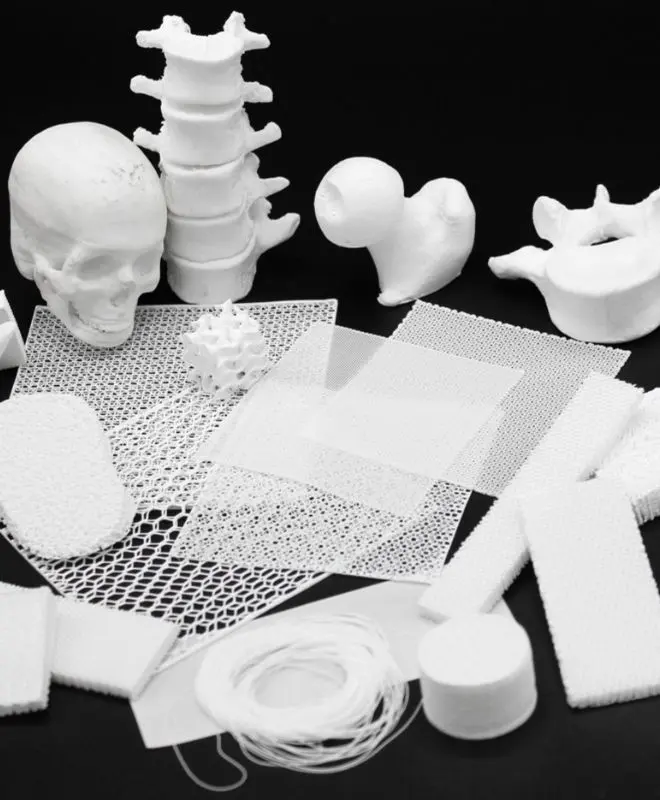

Revolutionizing Manufacturing with SLS 3D Printing

Discover how Selective Laser Sintering (SLS) 3D printing is transforming the manufacturing landscape. Our case studies showcase real-world applications and benefits across various industries.

Automotive

Aerospace

Medical

Eliminate tooling costs for low-volume production

Accelerate product development with quick turnaround times

Minimize waste with powder-based printing process

Explore how SLS 3D printing can revolutionize your production capabilities. Contact us today for a personalized consultation and discover the future of manufacturing.