In today’s fast-paced, innovation-driven era, businesses across industries are continuously seeking ways to streamline production, reduce costs, and maintain a competitive edge. Selective Laser Sintering (SLS) 3D printing, a revolutionary technology, not only meets these demands but also offers unparalleled customization and flexibility. Imagine transforming your ideas into physical products in a fraction of the time required by traditional craftsmanship—SLS 3D printing is turning this vision into reality.

SLS technology uses high-power lasers to sinter powder materials layer by layer into solid objects, enabling the creation of complex geometries that traditional manufacturing cannot achieve. This feature has made it the preferred solution for industries such as aerospace, automotive, healthcare, and consumer goods. However, the true charm of SLS lies in its customization capabilities—custom SLS 3D printing services help enterprises create unique products that perfectly fit specific needs.

This article delves into the world of custom SLS 3D printing services, analyzing the core principles of SLS technology, highlighting its significant advantages, and showcasing its diverse applications across industries. Additionally, we provide a guide to selecting the right service provider and explore the future prospects of this cutting-edge technology. Whether you are a seasoned expert or a novice in the 3D printing field, this comprehensive guide will empower you to harness the core strengths of custom SLS 3D printing. Let’s embark on this journey of customized solutions designed exclusively for you.

I. Understanding SLS 3D Printing

In recent years, Selective Laser Sintering (SLS) has become a cornerstone of advanced manufacturing, starkly differing from traditional production processes. But what exactly is SLS 3D printing, and why is it gaining popularity? This section analyzes the basic principles, unique advantages, and differences from other 3D printing methods of SLS technology.

What is SLS 3D Printing?

SLS 3D printing is an additive manufacturing process that uses high-power lasers to sinter powder materials into solid objects layer by layer. Unlike traditional manufacturing’s “subtractive process” (cutting materials), SLS builds objects from the bottom up using an “additive process,” supporting intricate and detailed designs.

Key Features of SLS:

- Material Versatility: Capable of using various materials such as nylon, metal powders, and ceramics.

- No Support Structures Needed: Surrounding powder automatically provides support during printing, allowing the creation of more complex shapes.

- Flexible Post-Processing: Parts can undergo surface treatments such as sanding and painting.

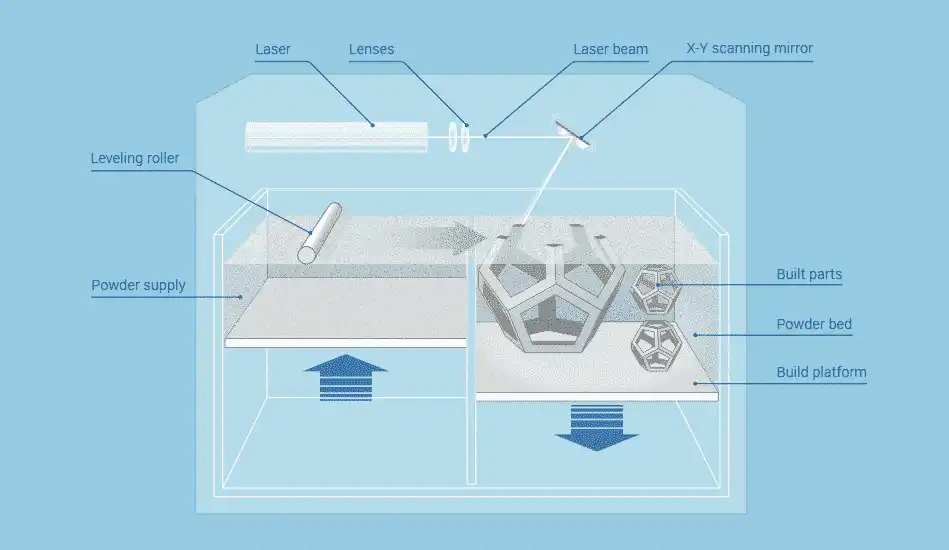

SLS Printing Process

The SLS printing process can be broken down into the following key steps:

- Preprocessing: Design a 3D model using CAD software and slice it into layers.

- Powder Spreading: Evenly spread a thin layer of powder material on the成型平台 (building platform).

- Sintering: The laser scans the powder surface according to the design trajectory, selectively heating and melting particles to bond them.

- Layer-by-Layer Repetition: After each layer is completed, the platform lowers, and the powder spreading and sintering steps are repeated until the object is formed.

- Cooling and Post-Processing: After printing, the part cools in the powder bed, followed by cleaning, sanding, or painting.

SLS Process Diagram

| Step | Description |

| Preprocessing | Design 3D model and slice into layers |

| Powder Spreading | Evenly spread a layer of powder |

| Sintering | Laser sinters powder layer by layer |

| Repetition | Layer-by-layer stacking until completion |

| Post-Processing | Cooling and surface treatment |

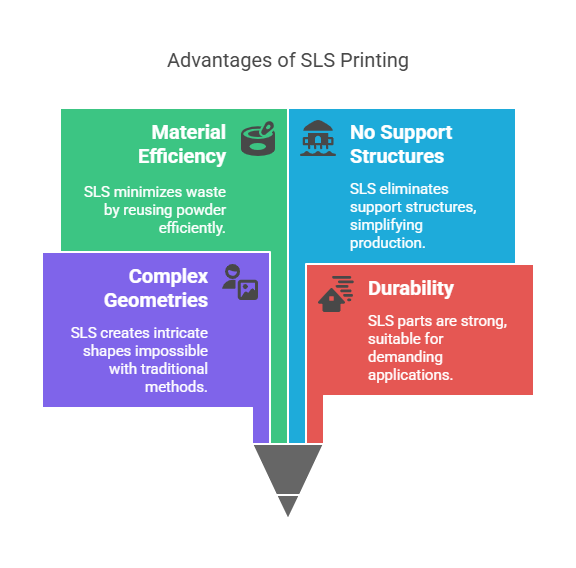

Advantages of SLS Technology

SLS technology offers multiple advantages, suitable for a wide range of scenarios:

- Complex Geometry Capability

- Can create complex shapes unattainable by traditional processes, such as internal hollow structures.

- Enables lightweight design by reducing material usage through internal cavities while maintaining strength.

- Strength and Durability

- Sintered parts exhibit high strength and durability, suitable for functional applications.

- Material properties are close to injection-molded parts, meeting industrial-grade requirements.

- Rapid Prototyping

- Greatly shortens the time from concept to production, supporting rapid iteration.

- Cost-effective for low-to-medium batch production compared to traditional processes.

- Low Material Waste

- Unsintered powder can be reused, significantly improving material utilization compared to subtractive processes.

Comparison with Other 3D Printing Technologies

| Technology | Process Type | Material Limitations | Advantages | Disadvantages |

| SLS | Powder Bed Fusion | Nylon, metal, ceramic | Complex shapes, no support needed | Longer printing time |

| FDM | Filament Extrusion | Plastic (ABS, PLA) | Low cost, easy to use | Limited detail, lower strength |

| SLA | Resin Printing | Photocurable resin | High detail, smooth surface | Limited material options, brittleness |

| DMLS | Metal 3D Printing | Metal powders | High precision, suitable for metal parts | High cost, requires specialized equipment |

SLS stands out for its ability to efficiently manufacture customized complex designs. From material versatility to rapid prototyping, its advantages are driving it to become a core technology for the future of manufacturing. Whether you need to produce functional parts or intricate designs, a deep understanding of SLS is key to unlocking its full potential. Next, we will explore the specific advantages of custom SLS 3D printing services and how they can revolutionize your projects.

II. Advantages of Custom SLS 3D Printing Services

As industries evolve amid technological变革 (transformations), the demand for customized solutions has reached unprecedented heights. Selective Laser Sintering (SLS) 3D printing provides an excellent platform for customized manufacturing, meeting the specific needs of various industries. This section delves into the core advantages of custom SLS services, analyzing how they enhance product development efficiency, reduce costs, and foster innovation.

1. Customization and Flexibility

The core competitiveness of SLS lies in its inherent customization capabilities, enabling enterprises to adjust designs flexibly according to project requirements.

- Design Adaptation: Can modify dimensions, shapes, and functional characteristics to meet unique needs.

- Rapid Iteration: Quickly adjusts prototypes based on user feedback or design changes.

- Personalized Production: Customizes products for individual customers, enhancing user experience and satisfaction.

Application Examples:

- Unique prototypes for testing and validation

- Marketing customized products incorporating brand logos

- Functional components tailored to specific equipment

2. Rapid Prototyping

In a highly competitive market, speed determines success. Custom SLS services excel in rapid prototyping, helping enterprises complete the entire design-to-production process at a record pace.

- Shortened Time-to-Market: Quickly validates design concepts and compresses product development cycles.

- Reduced Risk: Identifies design flaws early, minimizing rework costs in later stages.

- Innovation Catalyst: Rapid prototyping capabilities encourage experimentation and exploration of new ideas.

Development Cycle Comparison

| Stage | Traditional Process | SLS Custom Prototyping |

| Design | Weeks to months | Days to weeks |

| Testing | Lengthy iteration | Rapid feedback loop |

| Mass Production | Slow and costly | Fast and cost-effective |

3. Material Versatility

SLS supports a variety of materials, each with unique properties to meet both functional and aesthetic requirements.

- Common Materials:

- Nylon (PA): High strength and flexibility, suitable for functional parts.

- TPU (Thermoplastic Polyurethane): Excellent elasticity, ideal for rubber-like applications.

- Metal Powders (Aluminum, Stainless Steel): High strength and heat resistance, used in aerospace and other demanding scenarios.

- Ceramics: Heat-resistant and aesthetically pleasing, commonly used in consumer goods.

- Material Selection Considerations: Integrate performance requirements (e.g., strength, flexibility, heat resistance), application scenarios, and budget constraints.

4. Cost-Effectiveness

Although the initial investment in custom SLS services may be higher than traditional manufacturing, their long-term cost advantages are significant.

- Cost Optimization Factors:

- Low Waste: Unused powder can be recycled, resulting in far less material waste than subtractive processes.

- Low Labor Costs: Automated processes reduce reliance on manual labor.

- Batch Flexibility: Suitable for low-to-medium batch production, avoiding the high mold costs of traditional processes.

Cost Comparison: SLS vs. Traditional Processes

| 5. Design Capability Breakthroughs |

| Innovation Directions: |

| – Complex geometries: Manufacturing precision internal structures and lightweight components. |

| – Functional integration: Merging multiple components into a single part, reducing assembly time and failure points. |

| – Topological optimization: Using materials only in critical load-bearing areas to create stronger, lighter parts. |

5. Design Capability Breakthroughs

Custom SLS not only supports traditional designs but also enables innovative structures unattainable by traditional processes.

- Innovation Directions:

- Complex Geometries: Manufacturing precision internal structures and lightweight components.

- Functional Integration: Merging multiple components into a single part, reducing assembly time and failure points.

- Topological Optimization: Using materials only in critical load-bearing areas to create stronger, lighter parts.

Case References:

- Aerospace: Lightweight components improving fuel efficiency.

- Medical Field: Customized implants tailored to patients’ anatomical structures.

- Consumer Goods: Unique designs enhancing user experience and brand recognition.

Custom SLS 3D printing services significantly improve product development and manufacturing efficiency through unparalleled customization, rapid prototyping, material versatility, and cost-effectiveness. From aerospace to healthcare, and from consumer goods to industrial sectors, SLS technology empowers enterprises to innovate and adapt in a rapidly changing market. Regardless of your industry, exploring the advantages of custom SLS may be the key to unlocking new opportunities and achieving success. Next, we will delve into the specific applications of custom SLS across industries.

III. Application Fields of Custom SLS 3D Printing

With its versatility and unique advantages, Selective Laser Sintering (SLS) technology has been applied across numerous industries, revolutionizing product design and manufacturing. From aerospace to consumer goods, its ability to produce customized complex parts quickly and economically has made it the preferred solution for many enterprises. This section explores the core application scenarios of custom SLS 3D printing and how it is disrupting various industries.

1. Aerospace and Automotive Industries

In aerospace and automotive sectors, every component must meet strict safety and performance standards. Custom SLS 3D printing has become a transformative technology for these industries.

- Core Advantages:

- Lightweighting: SLS can manufacture high-strength lightweight structures, critical for improving fuel efficiency.

- Rapid Prototyping: Enterprises can rapidly iterate designs, shortening testing and validation cycles.

- Complex Geometry Manufacturing: Produces precision internal structure components unattainable by traditional processes.

Application Examples:

- Aerospace Components: Aerodynamic brackets, casings, and pipeline parts.

- Automotive Prototypes: Customized assembly parts used in design testing to ensure optimal performance before mass production.

2. Medical and Dental Fields

The medical field has extremely high requirements for precision, personalization, and reliability, which custom SLS 3D printing effectively meets.

- Advantages in Medical Applications:

- Personalized Implants: Customizes implants based on individual patient anatomical structures, improving fit and comfort.

- Medical Device Prototyping: Rapidly iterates and refines surgical tools, prosthetics, and other medical devices.

- Biocompatibility: Many SLS materials are biocompatible, suitable for direct use in medical scenarios.

Practical Applications:

- Prosthetics: Lightweight, custom-designed prosthetic limbs enhancing user functionality and comfort.

- Dental Products: Customized crowns, bridges, and orthodontic appliances tailored to patient needs.

3. Consumer Goods Industry

The consumer goods market is continuously evolving, with a strong emphasis on personalization and unique design. Custom SLS 3D printing helps enterprises efficiently respond to consumer demands.

- Advantages in Consumer Products:

- Unique Design: Creates intricate product aesthetics, helping stand out in a competitive market.

- Customization Services: Brands can offer personalized products, enhancing customer engagement and loyalty.

- Rapid Response: Short production cycles enable brands to quickly adapt to market trends.

Application Examples:

- Footwear: Comfortable shoe designs customized to individual foot shapes.

- Home Goods: Decorative items and functional tools tailored to consumer needs.

4. Industrial Applications

In industrial settings, the demand for functional parts and tooling is critical. Custom SLS 3D printing provides efficient solutions to these challenges.

- Advantages in Industrial Applications:

- Functional Prototyping: Manufactures parts testable in real-world scenarios, shortening development cycles.

- Tooling and Fixtures: Customized jigs, fixtures, and tools to improve production efficiency.

- Low-Volume Production: Economically produces specialized tools or parts, avoiding high costs of traditional manufacturing.

Industrial Scenarios:

- Manufacturing Tools: Custom fixtures enhancing assembly line efficiency or machine part precision.

- Spare Parts: Rapid production of hard-to-source components to ensure equipment operation.

5. Education and Research Fields

Educational institutions and research facilities are increasingly adopting SLS technology for teaching and innovative exploration.

- Advantages in Education and Research:

- Hands-On Teaching: Students gain exposure to cutting-edge technology and practical experience in 3D printing and design.

- Research Prototyping: Researchers can quickly create prototypes to test and optimize ideas.

- Innovation Catalyst: Custom SLS technology provides creative space for exploring new solutions.

Application Examples:

- Teaching Models: Anatomical models for medical students or design models for engineering programs.

- Research Prototypes: Prototypes developed in laboratory environments for new products or technologies.

The applications of custom SLS 3D printing are wide-ranging and diverse, making it a valuable tool across multiple industries. From aerospace and healthcare to consumer goods and education, its ability to produce customized complex components quickly and economically is driving innovation and efficiency. Next, we will discuss how to select a suitable custom SLS printing service provider to help you make informed decisions.

IV. Selecting a Suitable Custom SLS 3D Printing Service

Choosing the right custom SLS 3D printing service is critical to project success. With numerous service providers in the market, each differing in capabilities, materials, and pricing models, thorough research is essential before making a decision. This section guides you through key considerations, methods for evaluating service providers, and core questions to ask, ensuring you find the best fit for your needs.

1. Key Considerations

When evaluating custom SLS printing services, the following factors are crucial:

- Experience and Expertise: Select providers with proven success in SLS technology and industry-specific experience, as their expertise often guarantees project outcomes.

- Material Selection: Different applications require different materials; ensure the provider supports the required material types (e.g., strength, flexibility, surface treatment).

- Production Capacity: Assess whether the provider can handle project scale (from single prototypes to large-scale production) and deliver high-quality results by the deadline.

- Quality Control Processes: Understand their quality management measures to avoid defects and ensure parts meet specifications.

- Post-Processing Capabilities: Custom SLS services often require post-processing; confirm whether the provider offers additional services like sanding, painting, and assembly.

2. Steps to Evaluate Service Providers

- Initial Research and Screening:

- Conduct online searches for SLS printing service providers, read user reviews and recommendations, and shortlist candidates meeting preliminary criteria.

- Case Portfolio Review:

- Examine the provider’s past project cases, especially those similar to your industry or needs, to assess relevant experience.

- Obtain Quotes:

- Contact multiple providers, specify project requirements, and obtain accurate quotes for cost comparison.

- Request Client References:

- Ask providers for past client references to gain insights into their reliability and service quality through direct communication.

- Arrange Consultation Meetings:

- Discuss project details with providers to evaluate their expertise and communication skills.

3. Key Questions to Ask Potential Providers

- Materials: What SLS materials do you offer, and what are their performance parameters?

- Delivery Time: What is the typical delivery time for projects, and how are urgent requests handled?

- Quality Control: What quality management measures are implemented during production?

- Design Changes: Do you support design adjustments during projects?

- Post-Processing Services: What surface treatment options (e.g., painting, polishing, assembly) are available?

- Problem Resolution: How are production defects or issues addressed?

4. Cost Considerations

Cost is often a key decision factor; understand pricing structures for fair comparisons:

- Material Costs: Prices vary significantly across materials; clarify how material choices impact budgets.

- Setup Fees: Some providers charge setup fees for special processes or custom designs; confirm this in advance.

- Bulk Discounts: Inquire about price discounts for large orders to achieve cost savings.

- Shipping Costs: Do not overlook shipping fees for large or heavy parts.

Cost Comparison Dimensions

| [To be filled based on specific data] |

Selecting a custom SLS 3D printing service requires balancing factors like experience, materials, production capacity, and cost. By evaluating providers against the above criteria and asking key questions, you can ensure collaboration with a partner aligned with project goals. Next, we will look to the future of custom SLS printing, exploring innovations and trends shaping the industry.

V. Future Outlook for Custom SLS 3D Printing

Looking ahead, the development prospects of Selective Laser Sintering (SLS) technology are filled with opportunities. Rapid advancements in 3D printing are disrupting industries, breaking boundaries, and redefining manufacturing possibilities. This section discusses exciting innovations at the forefront of SLS technology, emerging market trends, and the industry’s growing focus on sustainability.

1. SLS Technological Innovations

The SLS field continues to evolve driven by technological advancements, continuously enhancing printing capabilities, materials, and processes:

- Advanced Material Development:

- High-Performance Materials: The introduction of new materials like composite materials and biobased powders expands SLS printing applications.

- Multi-Material Printing: Technological breakthroughs enable fusing multiple materials in a single print to create parts with composite properties.

- Faster Printing Technologies:

- Laser Scanning Speedup: Innovations in laser technology reduce printing time without compromising precision or quality.

- Thicker Layer Printing: Experiments with thicker powder layers significantly improve efficiency in large-scale production.

- Automation and AI Integration:

- Smart Manufacturing: Artificial intelligence optimizes design and printing workflows, enhancing quality control and interlayer bonding.

- Automated Post-Processing: Automation in post-processing stages improves efficiency and reduces manual labor costs for surface treatment.

2. Market Trends

Driven by multiple market trends, SLS technology adoption across industries continues to rise, signaling a shift in manufacturing models:

- Growing Demand for Customization:

- Personalized Products: Surging consumer demand for unique, customized products drives the development of customized manufacturing solutions.

- Modular Design: Enterprises explore modular design options, allowing customers to select functional configurations as needed.

- New Industry Expansion:

- Emerging Application Scenarios: SLS is breaking into traditional markets like fashion, art, and architecture, which rely heavily on unique designs and rapid prototyping.

- Adoption in Developing Markets: Developing countries are adopting SLS technology for local manufacturing, reducing reliance on imports.

- Rise of On-Demand Manufacturing:

- Just-in-Time Production: The shift to on-demand production reduces inventory costs and enables rapid response to market changes.

- Localized Manufacturing: Local production via SLS shortens transportation time and costs, enhancing supply chain efficiency.

3. Environmental Impact and Sustainability

As industry awareness of environmental responsibility grows, sustainability has become a core direction for SLS technology development. Custom SLS printing is contributing to a greener future in the following ways:

- Reduced Material Waste:

- Powder Recycling: SLS technology supports recycling of unused powder, significantly reducing waste compared to traditional processes.

- Efficient Material Use: Additive manufacturing uses materials only where needed, further minimizing waste.

- Sustainable Materials:

- Biobased Powders: Development of biobased and recyclable materials lays the foundation for more environmentally friendly manufacturing solutions.

- Sustainable Material Research: Ongoing research and development of SLS-compatible sustainable materials ensure products do not harm the environment.

- Energy Efficiency:

- Process Optimization: Continuous improvements in printing technology reduce energy consumption during production.

- Local Production: On-demand manufacturing reduces carbon footprints from transportation and logistics.

The future of custom SLS 3D printing will be defined by innovation, evolving market trends, and sustainability. As technology advances, industries will further benefit from enhanced manufacturing capabilities, higher efficiency, and the ability to meet consumer customization demands. Embracing these changes not only improves operational success but also drives manufacturing toward a more sustainable and responsible paradigm. As we conclude our exploration of custom SLS printing services, we encourage you to consider how leveraging these technological advancements can enhance your projects and achieve business transformation. Thank you for joining us on this journey through SLS technology!