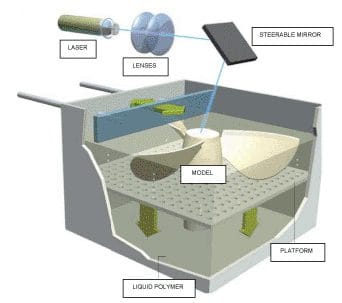

SLA (stereolithography) 3D printing technology has come a long way since it was first introduced in the 1980s. Today, it is one of the most popular forms of 3D printing, with its applications spanning across various industries. In this article, we will explore the potential of SLA 3D printing technology and its impact on industries like manufacturing, healthcare, and construction.

Faster Printing Speeds

One of the most significant advantages of SLA 3D printing technology is its faster printing speeds. With advancements in technology, it is now possible to print objects at a much faster rate than before. This has been particularly useful in manufacturing and construction industries where production times are critical.

For example, in the automotive industry, SLA 3D printing has revolutionized the production process by reducing the time it takes to create prototypes. This has allowed manufacturers to bring products to market faster and more efficiently.

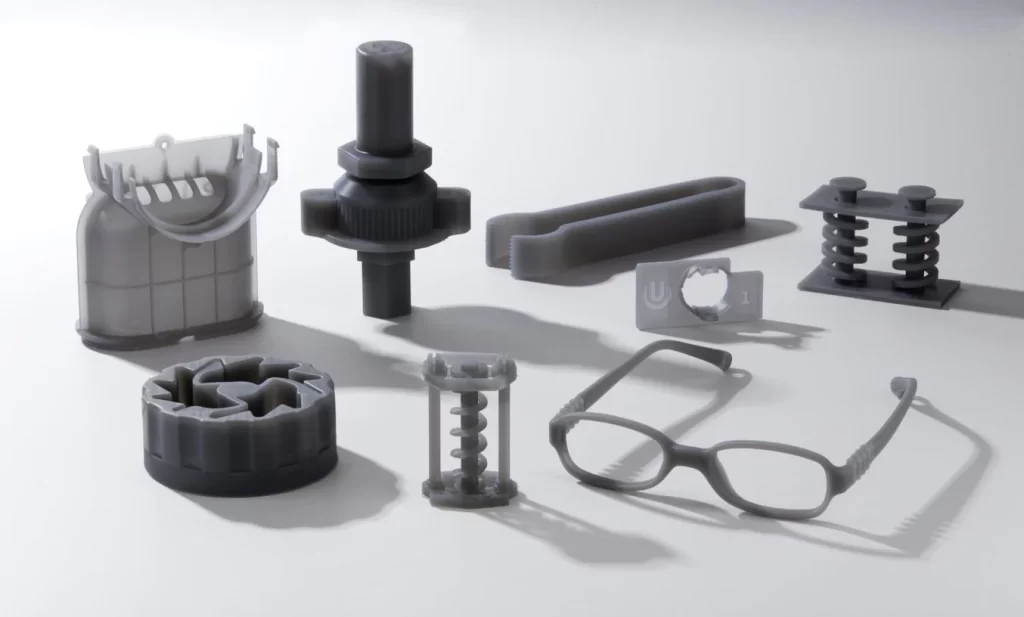

Multi-Material Printing

Another advantage of SLA 3D printing technology is its ability to print with multiple materials. This has been particularly useful in healthcare and manufacturing industries where product functionality and design are critical.

For instance, in the healthcare industry, multi-material printing has allowed for the creation of more complex medical devices that are tailored to individual patients’ needs. In the manufacturing industry, multi-material printing has enabled designers to create products with better functionality and aesthetics.

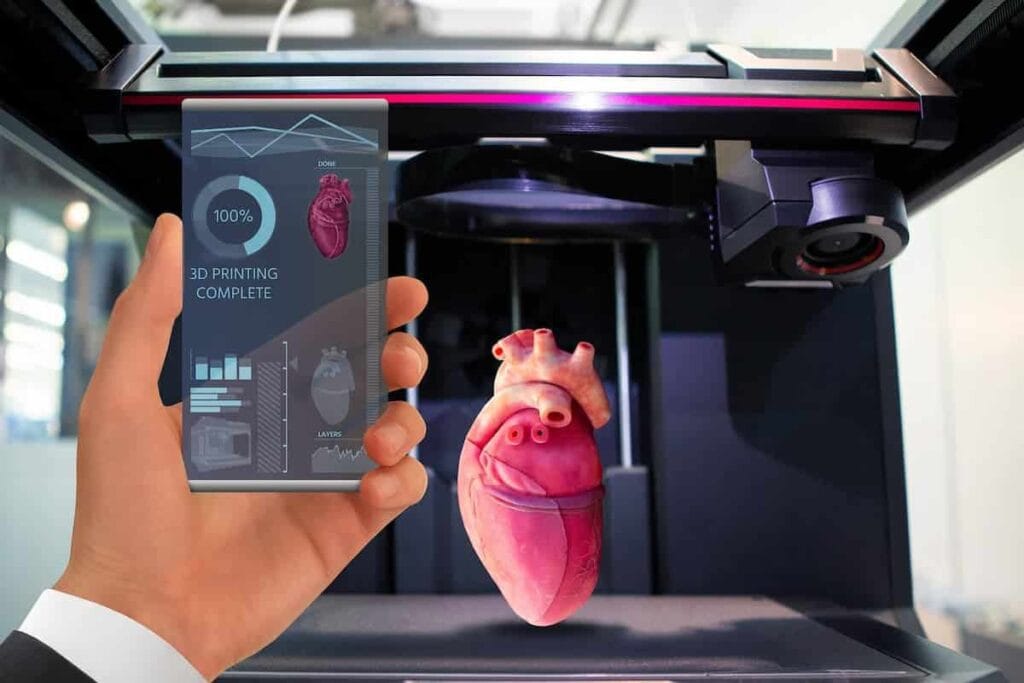

Bioprinting

Bioprinting is one of the most exciting developments in SLA 3D printing technology. It involves using living cells to create functional tissues or organs. This has significant implications for the healthcare industry, particularly in organ transplantation and drug testing.

For example, bioprinting has been used to create functional liver tissues that can be used for drug testing. It has also been used to create artificial skin for burn victims.

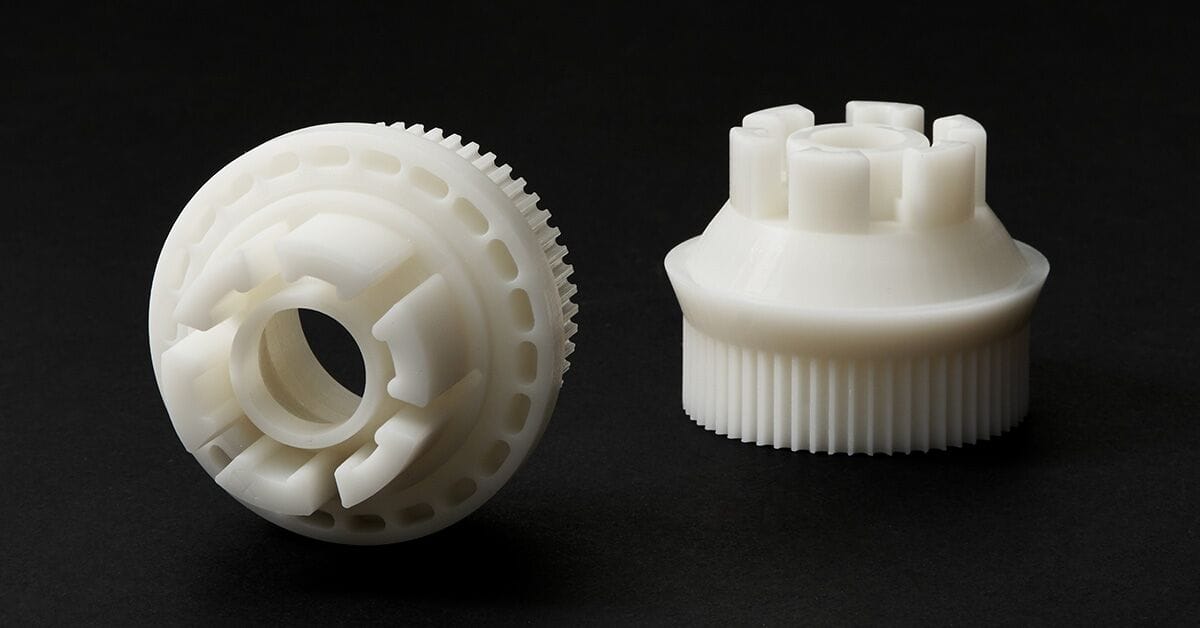

Impact on Manufacturing Industry

SLA 3D printing technology is changing the manufacturing industry by improving production times and reducing costs. With faster printing speeds and multi-material printing capabilities, manufacturers can bring products to market faster and more efficiently.

In addition, SLA 3D printing technology allows manufacturers to create more complex designs that were previously impossible to manufacture. This has led to a wave of innovation in the manufacturing industry, with designers creating products that are more functional and aesthetically pleasing

Impact on Healthcare Industry

SLA 3D printing technology is also changing the healthcare industry by improving medical device production and organ transplantation. With multi-material printing and bioprinting capabilities, healthcare professionals can create more complex medical devices and tissues that are tailored to individual patients’ needs.

For example, 3D printing has been used to create prosthetic limbs, dental implants, and even cranial implants. Bioprinting has also been used to create functional tissues and organs for transplantation, such as heart valves and blood vessels.

Impact on Construction Industry

SLA 3D printing technology is also changing the construction industry by improving building design and construction times. With faster printing speeds and multi-material printing capabilities, designers can create more complex and sustainable buildings that were previously impossible to construct.

For example, 3D printing has been used to create entire houses and buildings, reducing construction times and costs significantly. This has significant implications for the future of sustainable architecture and urban planning.

Challenges and Limitations

Despite the many advantages of SLA 3D printing technology, there are still some challenges and limitations that need to be addressed. One of the biggest challenges is the high cost of SLA 3D printers, which can be a barrier to entry for smaller businesses and individuals.

In addition, there are still limitations in the materials that can be used in SLA 3D printing, particularly in bioprinting. There are also concerns around the safety of using 3D printed medical devices and tissues in patients.

In conclusion, SLA 3D printing technology has the potential to revolutionize various industries, including manufacturing, healthcare, and construction. With faster printing speeds, multi-material printing capabilities, and bioprinting, designers can create more complex and functional products that were previously impossible to manufacture.

However, there are still challenges and limitations that need to be addressed before SLA 3D printing technology can reach its full potential. Nevertheless, it is clear that SLA 3D printing technology is here to stay, and its impact on various industries will only continue to grow in the future.