In today’s fast-paced world, innovation is the key to success. Businesses across various industries are constantly seeking new ways to bring their ideas to life and stay ahead of the competition. One technology that has revolutionized the prototyping process is SLA 3D printing. In this article, we will explore how SLA 3D printing can turn concepts into reality and help businesses create functional prototypes with incredible precision and efficiency.

Understanding SLA 3D Printing

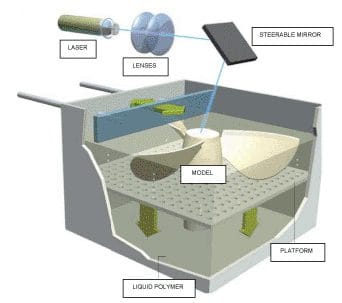

SLA, or Stereolithography, is an additive manufacturing process that uses a liquid resin cured by ultraviolet light to create three-dimensional objects layer by layer. This technology allows for the production of highly detailed and accurate prototypes with intricate geometries that may be challenging to achieve using traditional manufacturing methods.

The Benefits of SLA 3D Printing for Prototyping

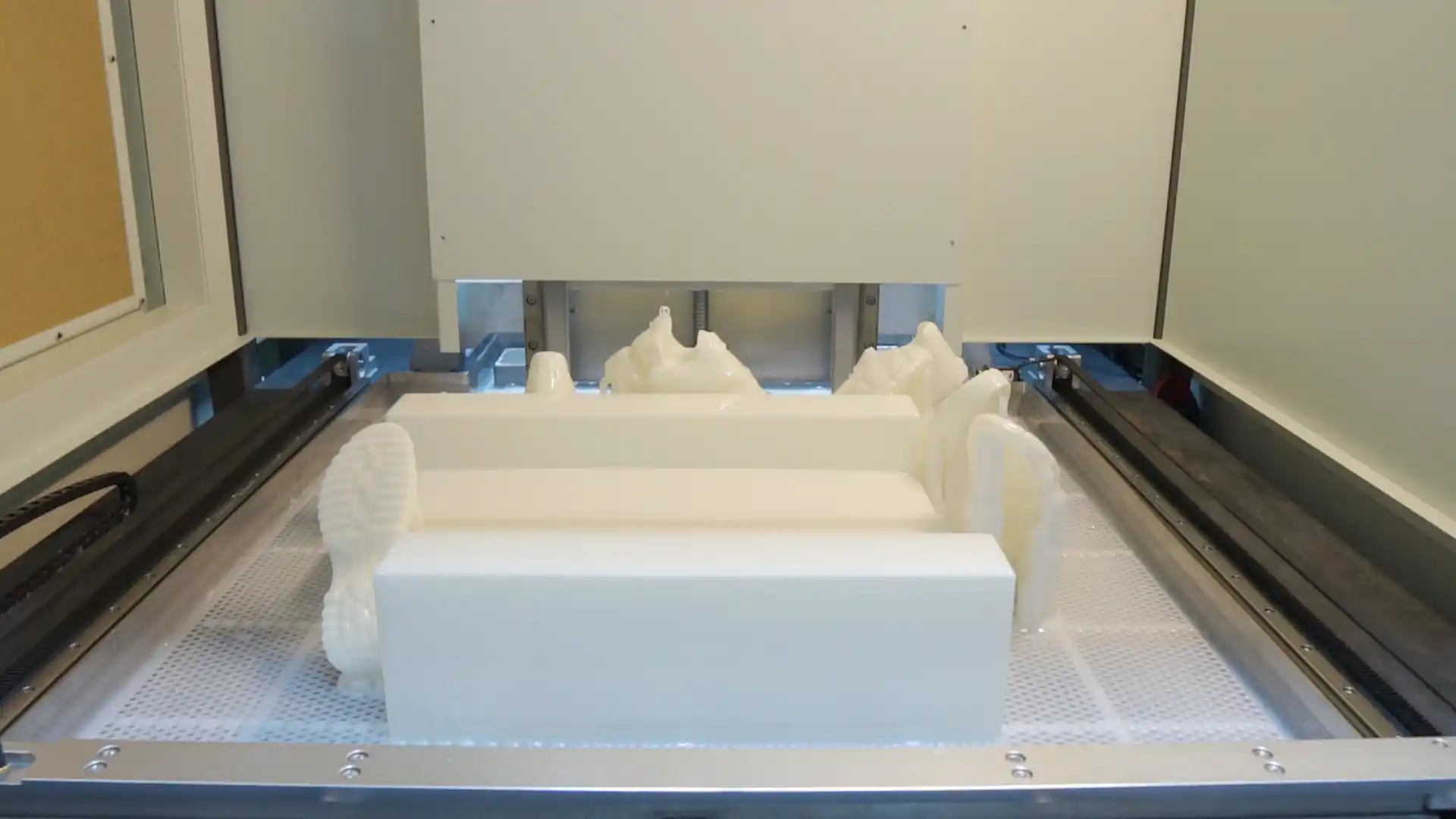

1. Speed and Efficiency: SLA 3D printing enables rapid prototyping, significantly reducing the time it takes to transform an idea into a physical prototype. Traditional prototyping methods often involve lengthy lead times, tooling costs, and complex processes. With SLA 3D printing, businesses can iterate quickly and make design improvements on the fly, saving both time and money.

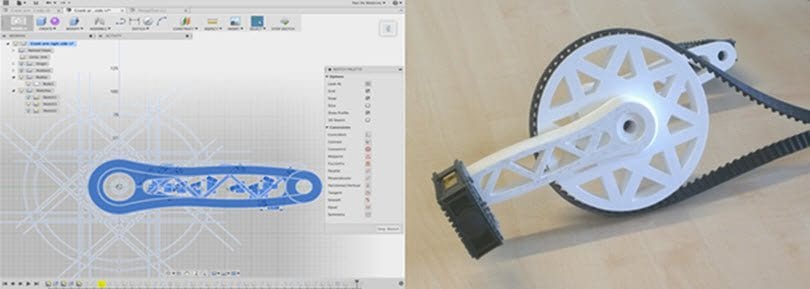

2. High Precision and Accuracy: SLA 3D printers can produce prototypes with exceptional detail and accuracy, capturing even the finest features of a design. This level of precision allows designers and engineers to evaluate the functionality and aesthetics of a product before moving forward with mass production, minimizing the risk of costly errors or design flaws.

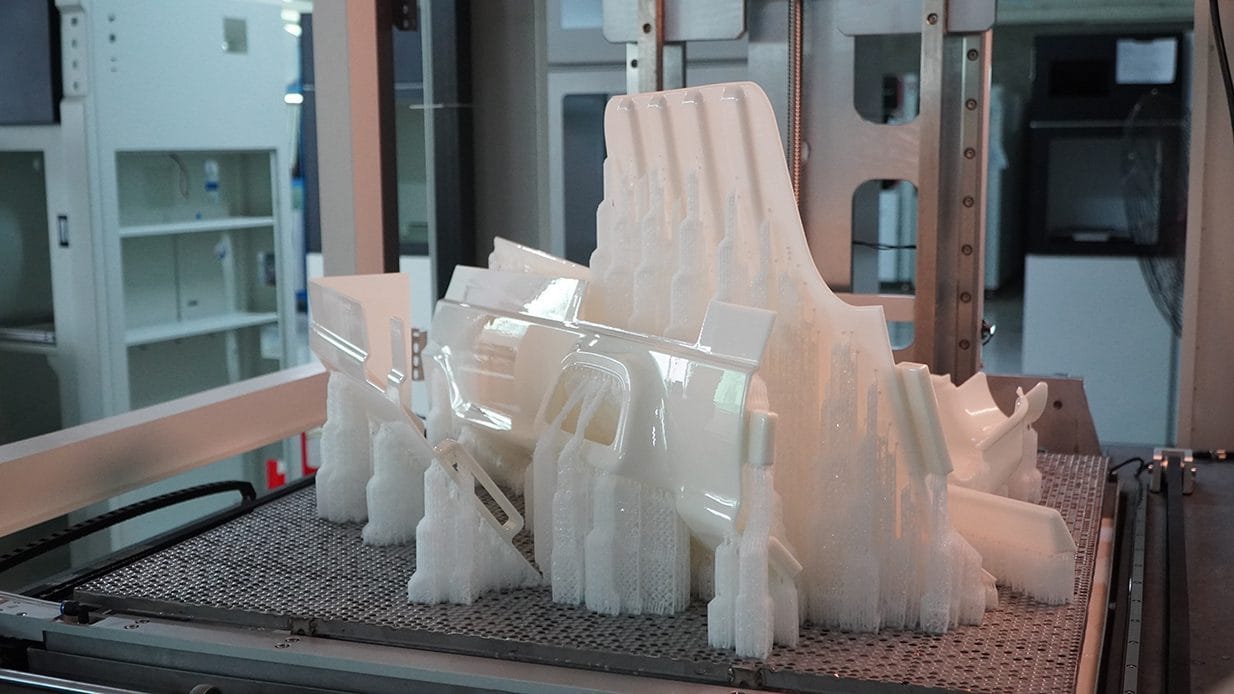

3. Versatility in Material Selection: SLA 3D printing supports a wide range of materials, including various resins with different mechanical properties. This versatility allows businesses to choose the most suitable material for their specific application, whether it’s creating prototypes for consumer products, medical devices, automotive parts, or architectural models. 4. Complex Geometries Made Easy: SLA 3D printing excels at producing intricate geometries and complex shapes that may be impossible or extremely challenging to manufacture using traditional methods. This capability opens up new design possibilities and empowers businesses to push the boundaries of innovation, creating products that were once deemed unattainable.

Applications of SLA 3D Printing in Various Industries

1. Product Design and Development: SLA 3D printing is a game-changer in the product development cycle. Designers can quickly transform their concepts into tangible prototypes, allowing for thorough testing and validation before committing to mass production. This iterative process helps identify design flaws early on, saving time and resources in the long run.

2. Medical and Healthcare: The medical industry heavily relies on accurate and customized solutions. SLA 3D printing enables the production of patient-specific anatomical models, surgical guides, prosthetics, and implants. This technology facilitates better surgical planning, reduces operating time, and improves patient outcomes.

3. Automotive and Aerospace: SLA 3D printing plays a significant role in the automotive and aerospace sectors. It allows engineers to create lightweight components with complex geometries, reducing overall weight and improving fuel efficiency. Additionally, functional prototypes can be developed to test aerodynamic performance, ergonomics, and overall functionality.

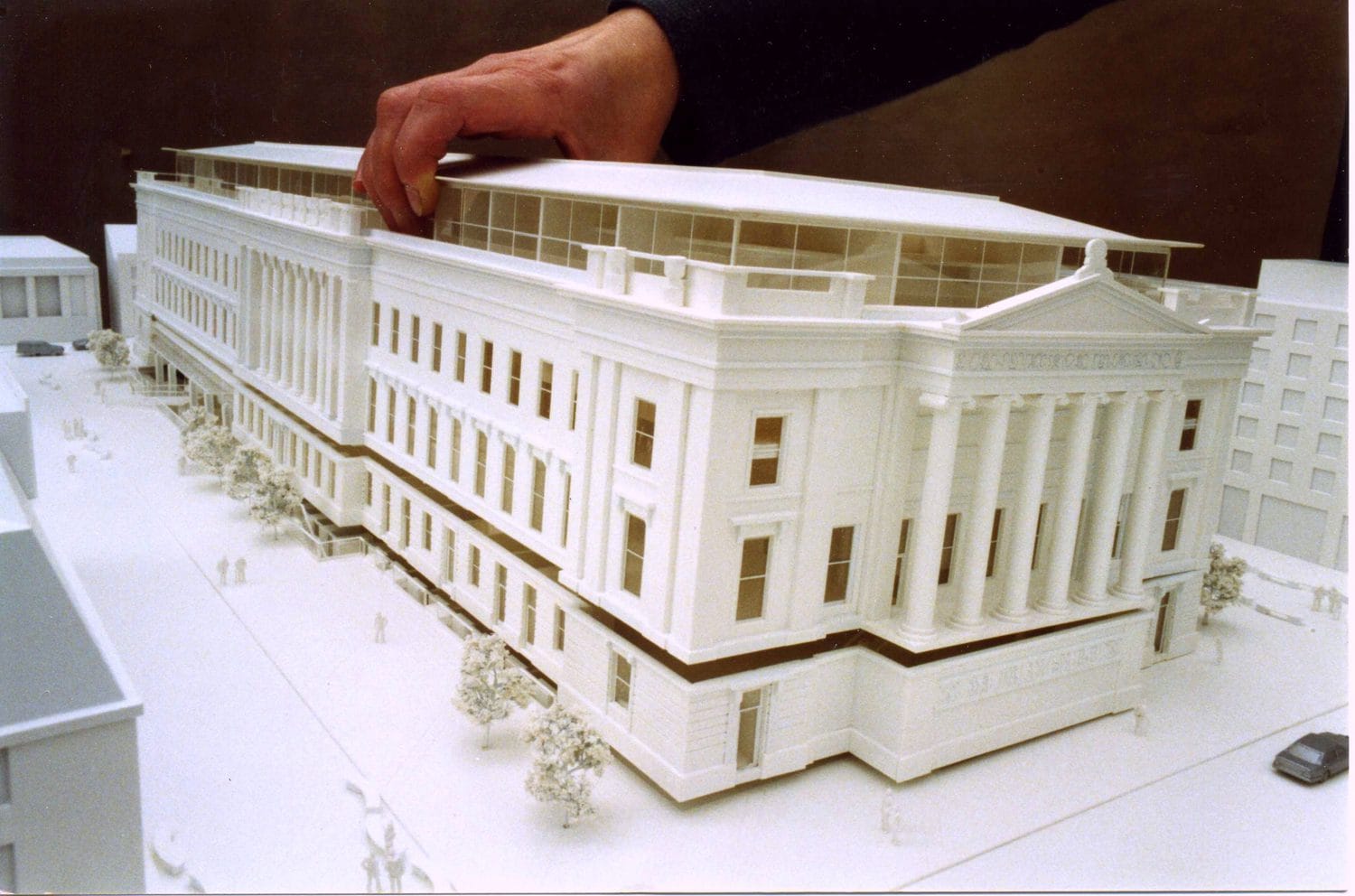

4. Architecture and Construction: Architects and designers leverage SLA 3D printing to create detailed architectural models, showcasing intricate facades, interior spaces, and landscaping. This technology aids in visualizing the final structure, identifying design flaws, and communicating ideas effectively to clients and stakeholders.

Choosing the Right SLA 3D Printing Service Provider

When embarking on the journey of turning concepts into reality with SLA 3D printing, partnering with the right service provider is crucial. Here are some factors to consider:

1. Expertise and Experience: Look for a service provider with a proven track record in SLA 3D printing and a deep understanding of the technology. They should have experience working with various industries and be able to provide samples and case studies showcasing their capabilities.

2. Quality and Precision: Ensure that the service provider can deliver high-quality prototypes with exceptional accuracy and surface finish. Request to see physical samples or images of their previous work to assess the quality of their output.

3. Material Selection: Check if the service provider offers a wide range of materials suitable for your specific application. They should be knowledgeable about the properties of different resins and be able to recommend the most suitable material for your project.

4. Customer Support and Communication: Effective communication and responsive customer support are vital for a successful collaboration. Choose a service provider that values clear and prompt communication, understands your requirements, and provides regular updates throughout the project.

In conclusion, SLA 3D printing has revolutionized the prototyping process, allowing businesses to bring their concepts to life with speed, precision, and versatility. By leveraging this advanced technology, companies can iterate quickly, reduce development costs, and gain a competitive edge in the market. Whether in product design, healthcare, automotive, or architecture, SLA 3D printing is transforming industries and enabling innovation like never before.