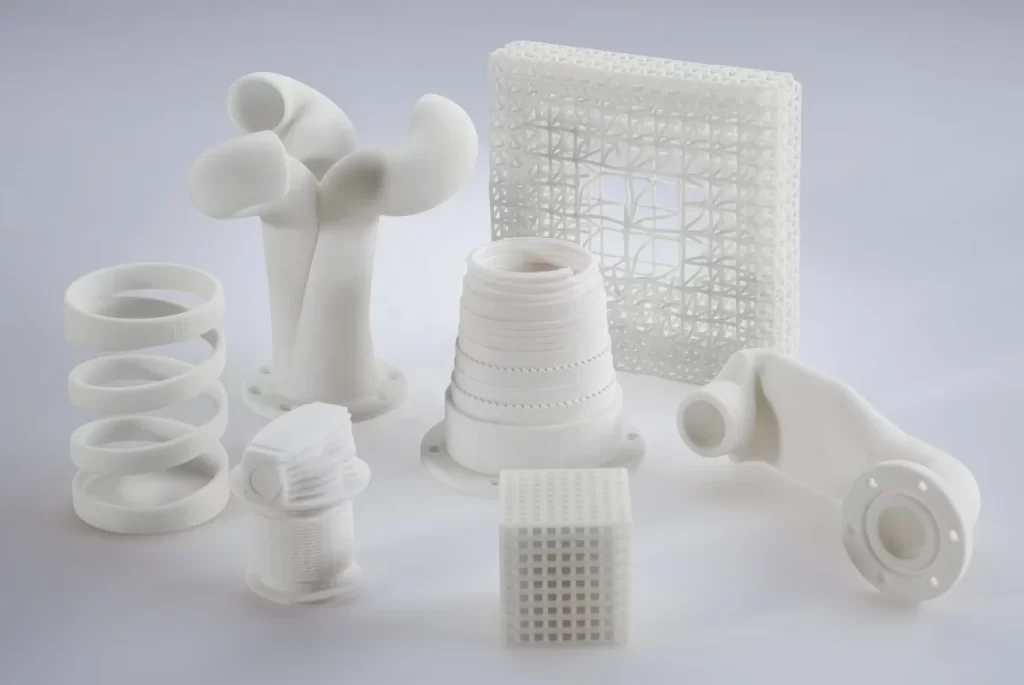

In the world of manufacturing and design, a revolution is taking place. This revolution is powered by a technology that is transforming industries across the globe – SLA 3D printing. But what is SLA 3D printing and why is it making such a significant impact? Let’s dive in and explore.

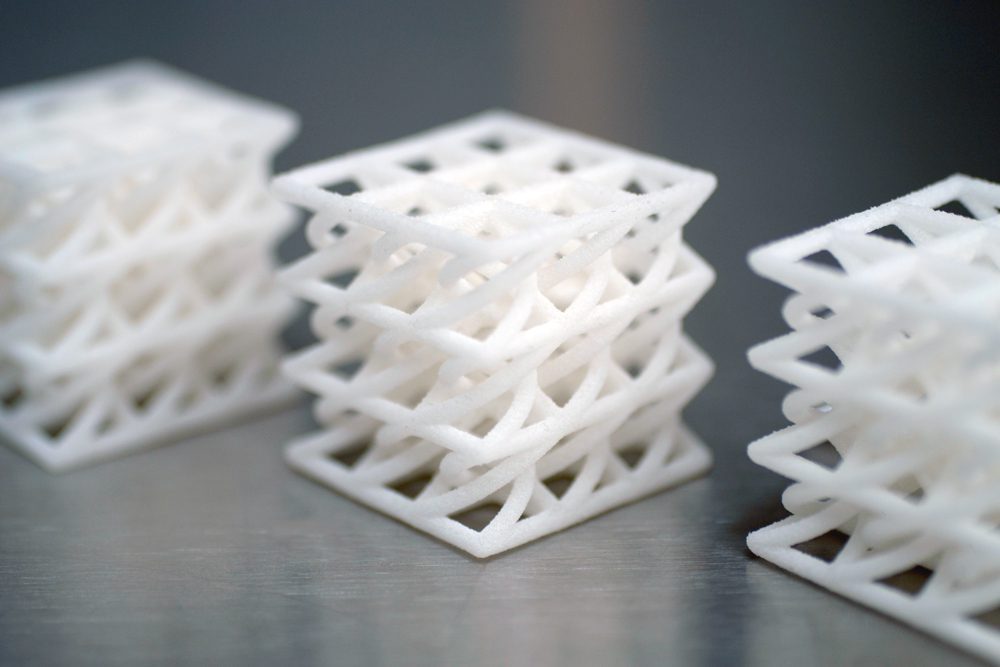

SLA 3D printing, or Stereolithography Additive Manufacturing, is a technology that uses a laser to selectively fuse a photo-sensitive resin. This process allows for the creation of complex, three-dimensional objects with a high degree of precision. But it’s not just about creating objects. SLA 3D printing is a versatile technology that is being used in a wide range of industries, each with its own unique applications.

In this article, we will delve into the world of SLA 3D printing, exploring its uses across various industries. From healthcare to automotive, from aerospace to dentistry, SLA 3D printing is making a significant impact. We will explore how this technology is being used to create everything from medical devices to automotive parts, and how it’s revolutionizing the way we think about manufacturing and design.

So, if you’re curious about the future of manufacturing and design, or if you’re already an expert in the field and want to learn more about the latest advancements, this article is for you. Let’s get started and uncover the world of SLA 3D printing.

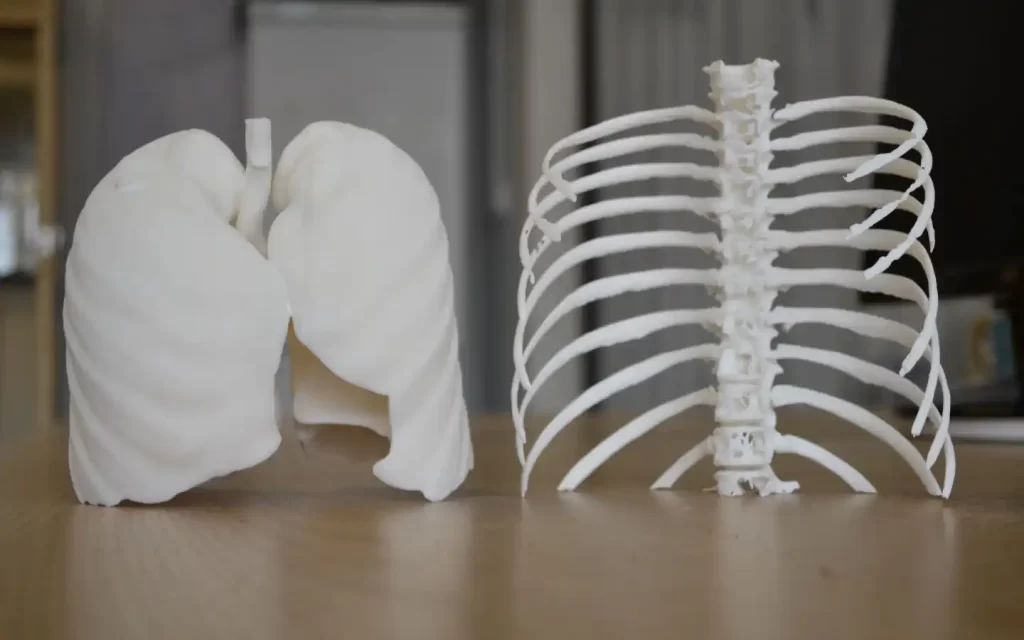

Industry 1: Healthcare

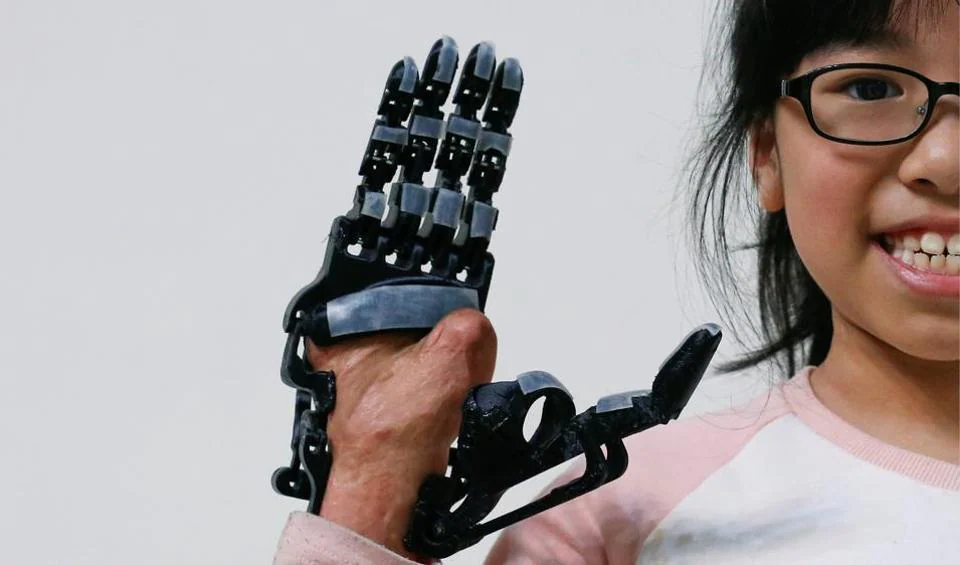

The healthcare industry is one of the most rapidly evolving sectors in the world today. With advancements in technology and a growing demand for personalized healthcare solutions, the healthcare industry is constantly seeking innovative ways to improve patient care and outcomes. One such innovation is SLA 3D printing.

SLA 3D printing is a technology that has the potential to revolutionize the healthcare industry. It allows for the creation of customized medical devices and prosthetics, providing a more personalized and effective treatment for patients.

The Role of SLA 3D Printing in Healthcare

SLA 3D printing plays a crucial role in healthcare in several ways:

- Customized Medical Devices: SLA 3D printing allows for the creation of customized medical devices that can be tailored to the specific needs of each patient. This includes everything from prosthetics and orthotics to customized implants and surgical instruments.

- Rapid Prototyping: SLA 3D printing enables rapid prototyping, allowing healthcare professionals to test new treatments and procedures before they are implemented on a larger scale.

- Cost-Effective: Compared to traditional manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for healthcare providers who are looking to reduce costs without compromising on quality.

Examples of SLA 3D Printed Medical Devices

SLA 3D printing has been used to create a variety of medical devices, including:

- Prosthetics: SLA 3D printing has been used to create customized prosthetics that can be tailored to the specific needs of each patient. This includes everything from limbs to facial prosthetics.

- Orthotics: SLA 3D printing has also been used to create customized orthotics, providing patients with the support they need to improve their mobility and quality of life.

- Implants: SLA 3D printing has been used to create customized implants, providing patients with a more personalized and effective treatment option.

- Surgical Instruments: SLA 3D printing has been used to create customized surgical instruments, providing surgeons with the tools they need to perform complex procedures with precision and accuracy.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the healthcare industry. By enabling the creation of customized medical devices and providing a cost-effective solution, SLA 3D printing is helping to improve patient care and outcomes. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the healthcare industry.

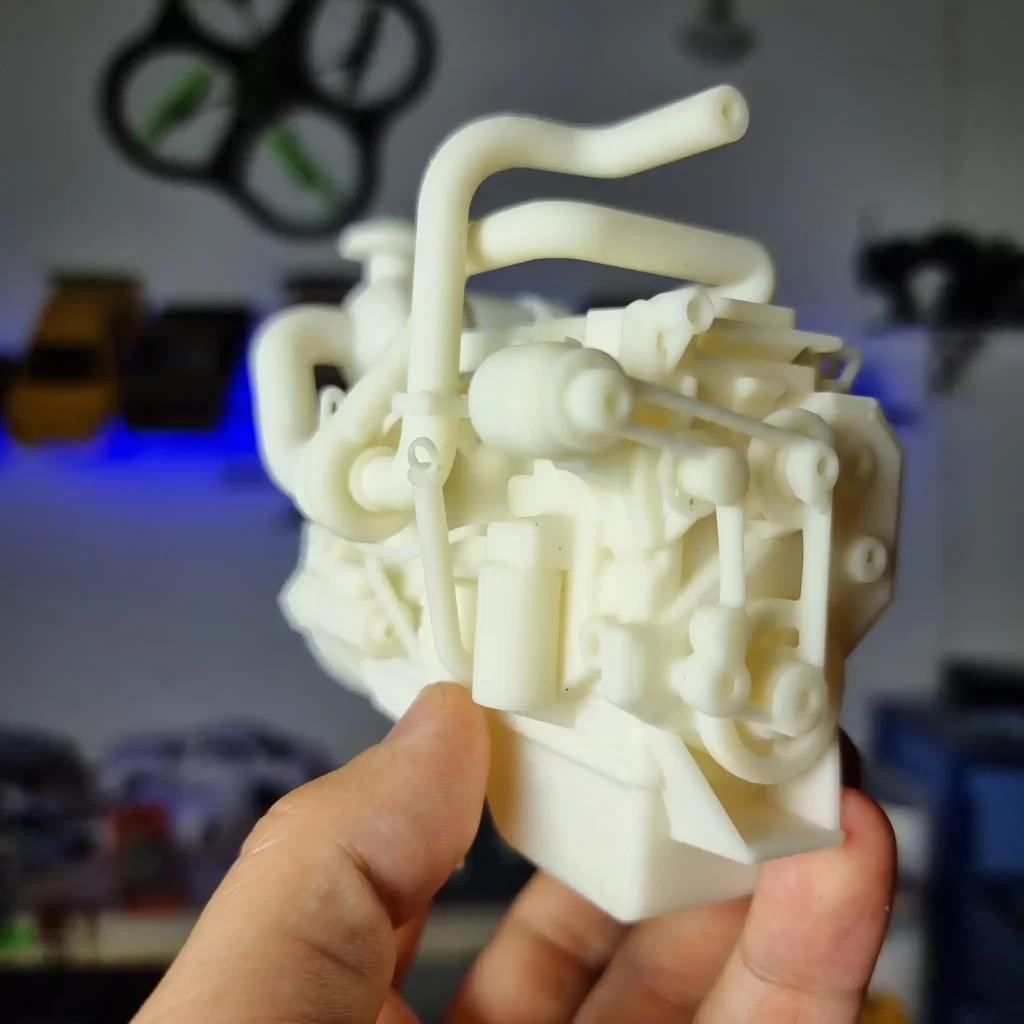

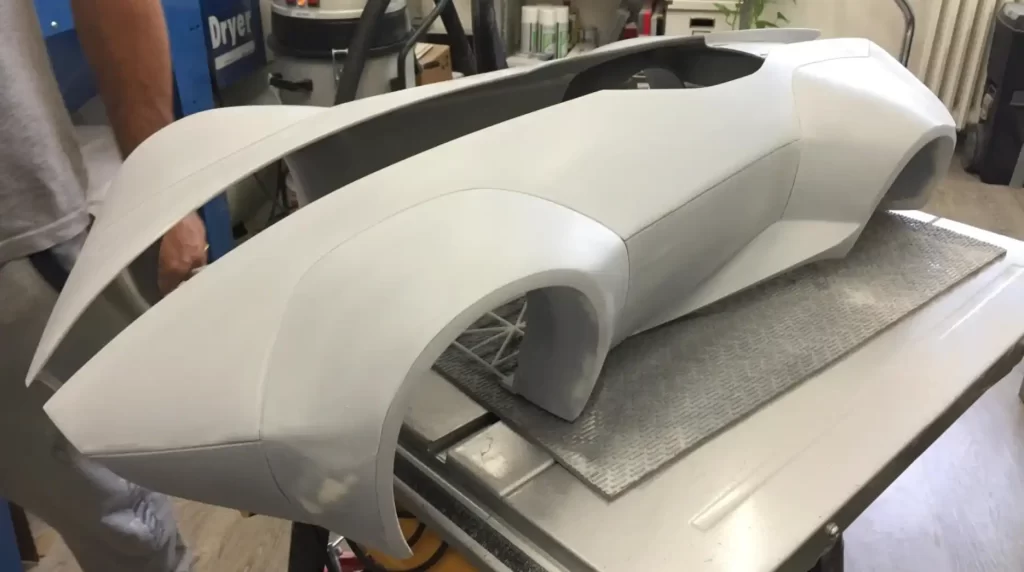

Industry 2: Automotive

The automotive industry is a testament to human ingenuity and innovation. From the first horseless carriage to the electric vehicles of today, the automotive industry has always been at the forefront of technological advancements. One such advancement is SLA 3D printing.

SLA 3D printing is a technology that is transforming the automotive industry. It allows for the creation of complex, three-dimensional parts with a high degree of precision, making it an ideal solution for manufacturers looking to improve their production processes and reduce costs.

The Role of SLA 3D Printing in Automotive

SLA 3D printing plays a crucial role in the automotive industry in several ways:

- Prototyping: SLA 3D printing enables rapid prototyping, allowing manufacturers to test new designs and concepts before they are implemented on a larger scale.

- Customization: SLA 3D printing allows for the creation of customized parts, providing manufacturers with the flexibility to meet the unique needs of each customer.

- Cost-Effective: Compared to traditional manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for manufacturers who are looking to reduce costs without compromising on quality.

Examples of SLA 3D Printed Automotive Parts

SLA 3D printing has been used to create a variety of automotive parts, including:

- Engine Components: SLA 3D printing has been used to create customized engine components, providing manufacturers with the flexibility to meet the unique needs of each engine.

- Body Panels: SLA 3D printing has been used to create customized body panels, providing manufacturers with the flexibility to meet the unique needs of each vehicle.

- Interior Components: SLA 3D printing has been used to create customized interior components, providing manufacturers with the flexibility to meet the unique needs of each vehicle.

- Suspension Components: SLA 3D printing has been used to create customized suspension components, providing manufacturers with the flexibility to meet the unique needs of each vehicle.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the automotive industry. By enabling the creation of customized parts and providing a cost-effective solution, SLA 3D printing is helping to improve production processes and reduce costs. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the automotive industry.

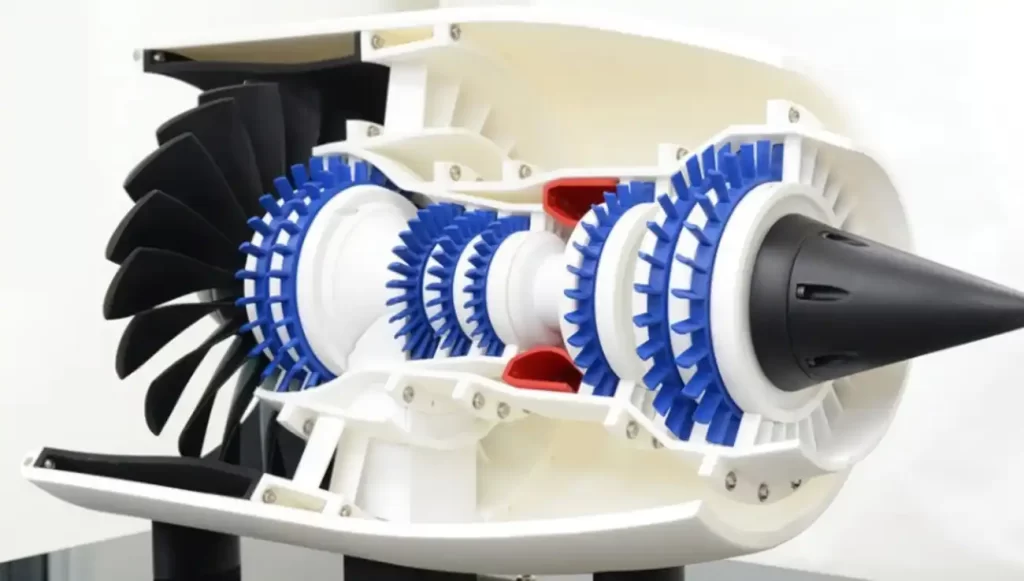

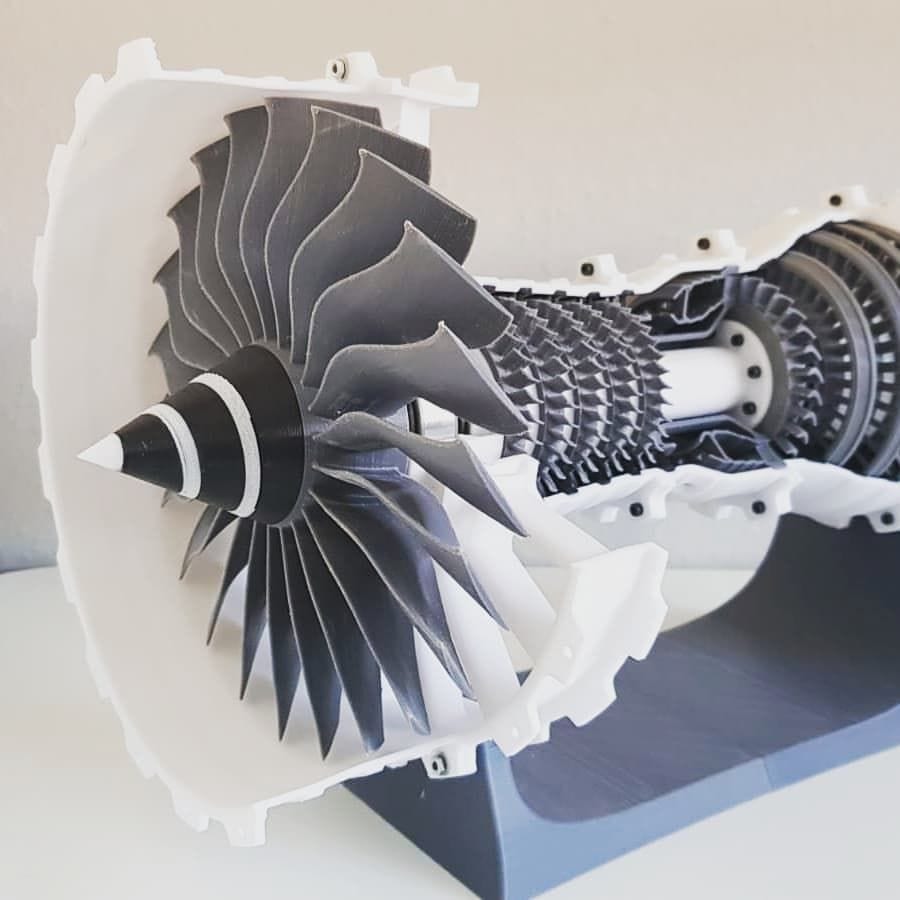

Industry 3: Aerospace

The aerospace industry is a testament to human innovation and ingenuity. From the first airplane to the spacecraft of today, the aerospace industry has always been at the forefront of technological advancements. One such advancement is SLA 3D printing.

SLA 3D printing is a technology that is transforming the aerospace industry. It allows for the creation of complex, three-dimensional parts with a high degree of precision, making it an ideal solution for manufacturers looking to improve their production processes and reduce costs.

The Role of SLA 3D Printing in Aerospace

SLA 3D printing plays a crucial role in the aerospace industry in several ways:

- Prototyping: SLA 3D printing enables rapid prototyping, allowing manufacturers to test new designs and concepts before they are implemented on a larger scale.

- Customization: SLA 3D printing allows for the creation of customized parts, providing manufacturers with the flexibility to meet the unique needs of each customer.

- Cost-Effective: Compared to traditional manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for manufacturers who are looking to reduce costs without compromising on quality.

Examples of SLA 3D Printed Aerospace Parts

SLA 3D printing has been used to create a variety of aerospace parts, including:

- Engine Components: SLA 3D printing has been used to create customized engine components, providing manufacturers with the flexibility to meet the unique needs of each engine.

- Body Panels: SLA 3D printing has been used to create customized body panels, providing manufacturers with the flexibility to meet the unique needs of each aircraft.

- Interior Components: SLA 3D printing has been used to create customized interior components, providing manufacturers with the flexibility to meet the unique needs of each aircraft.

- Suspension Components: SLA 3D printing has been used to create customized suspension components, providing manufacturers with the flexibility to meet the unique needs of each aircraft.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the aerospace industry. By enabling the creation of customized parts and providing a cost-effective solution, SLA 3D printing is helping to improve production processes and reduce costs. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the aerospace industry.

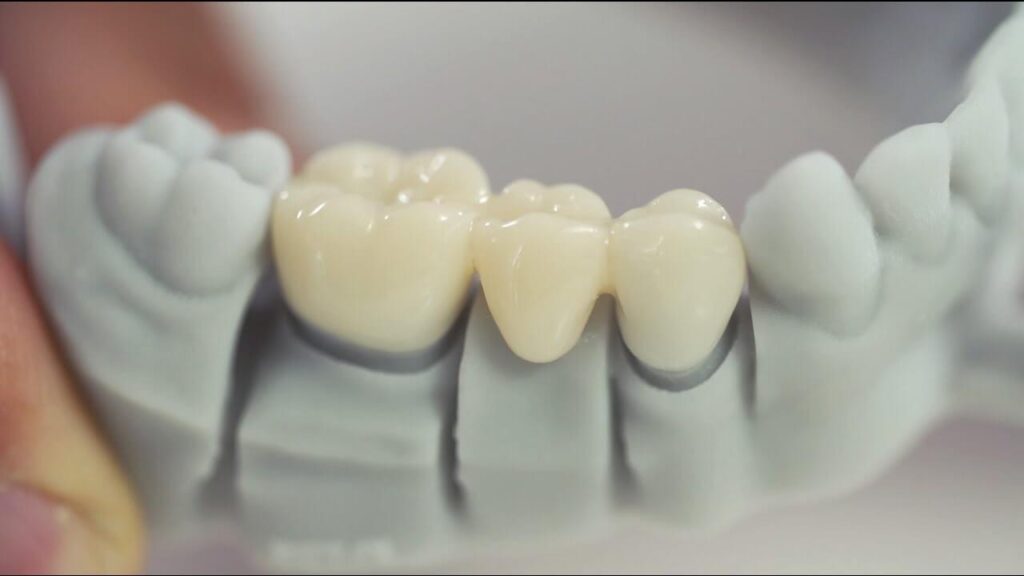

Industry 4: Dentistry

The dentistry industry has been a pioneer in the application of SLA 3D printing technology, transforming the way dental professionals create customized dental appliances and prosthetics.

SLA 3D printing, also known as stereolithography, is a technology that allows for the creation of complex, three-dimensional parts with a high degree of precision. This technology has found a significant application in the dentistry industry, where it enables the production of customized dental appliances and prosthetics .

The Role of SLA 3D Printing in Dentistry

SLA 3D printing plays a crucial role in the dentistry industry in several ways:

- Prototyping: SLA 3D printing enables rapid prototyping, allowing dentists to test new designs and concepts before they are implemented on a larger scale. This can lead to significant cost savings by identifying and fixing design issues early in the development process.

- Customization: SLA 3D printing allows for the creation of customized dental appliances, providing dentists with the flexibility to meet the unique needs of each patient. This can lead to increased patient satisfaction and loyalty.

- Cost-Effective: Compared to traditional dental manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for dentists who are looking to reduce costs without compromising on quality.

Examples of SLA 3D Printed Dental Parts

SLA 3D printing has been used to create a variety of dental parts, including:

- Dental Crowns: SLA 3D printing has been used to create customized dental crowns, providing dentists with the flexibility to meet the unique needs of each patient.

- Dental Implants: SLA 3D printing has been used to create customized dental implants, providing dentists with the flexibility to meet the unique needs of each patient.

- Orthodontic Appliances: SLA 3D printing has been used to create customized orthodontic appliances, providing dentists with the flexibility to meet the unique needs of each patient.

- Prosthodontic Restorations: SLA 3D printing has been used to create customized prosthodontic restorations, providing dentists with the flexibility to meet the unique needs of each patient.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the dentistry industry. By enabling the creation of customized dental appliances and providing a cost-effective solution, SLA 3D printing is helping to improve dental procedures and reduce costs. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the dentistry industry.

Industry 5: Jewelry

The jewelry industry is a creative field that has been increasingly turning to the modern technology of 3D printing to improve design and production processes. SLA 3D printing, also known as stereolithography, is a technology that allows for the creation of complex, three-dimensional parts with a high degree of precision. This technology has found a significant application in the jewelry industry, where it enables the production of customized jewelry pieces.

The Role of SLA 3D Printing in Jewelry

SLA 3D printing plays a crucial role in the jewelry industry in several ways:

- Prototyping: SLA 3D printing enables rapid prototyping, allowing jewelers to test new designs and concepts before they are implemented on a larger scale. This can lead to significant cost savings by identifying and fixing design issues early in the development process.

- Customization: SLA 3D printing allows for the creation of customized jewelry pieces, providing jewelers with the flexibility to meet the unique needs of each customer. This can lead to increased customer satisfaction and loyalty.

- Cost-Effective: Compared to traditional jewelry manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for jewelers who are looking to reduce costs without compromising on quality.

Examples of SLA 3D Printed Jewelry Parts

SLA 3D printing has been used to create a variety of jewelry parts, including:

- Rings: SLA 3D printing has been used to create customized rings, providing jewelers with the flexibility to meet the unique needs of each customer.

- Necklaces: SLA 3D printing has been used to create customized necklaces, providing jewelers with the flexibility to meet the unique needs of each customer.

- Earrings: SLA 3D printing has been used to create customized earrings, providing jewelers with the flexibility to meet the unique needs of each customer.

- Bracelets: SLA 3D printing has been used to create customized bracelets, providing jewelers with the flexibility to meet the unique needs of each customer.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the jewelry industry. By enabling the creation of customized jewelry pieces and providing a cost-effective solution, SLA 3D printing is helping to improve jewelry production processes and reduce costs. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the jewelry industry.

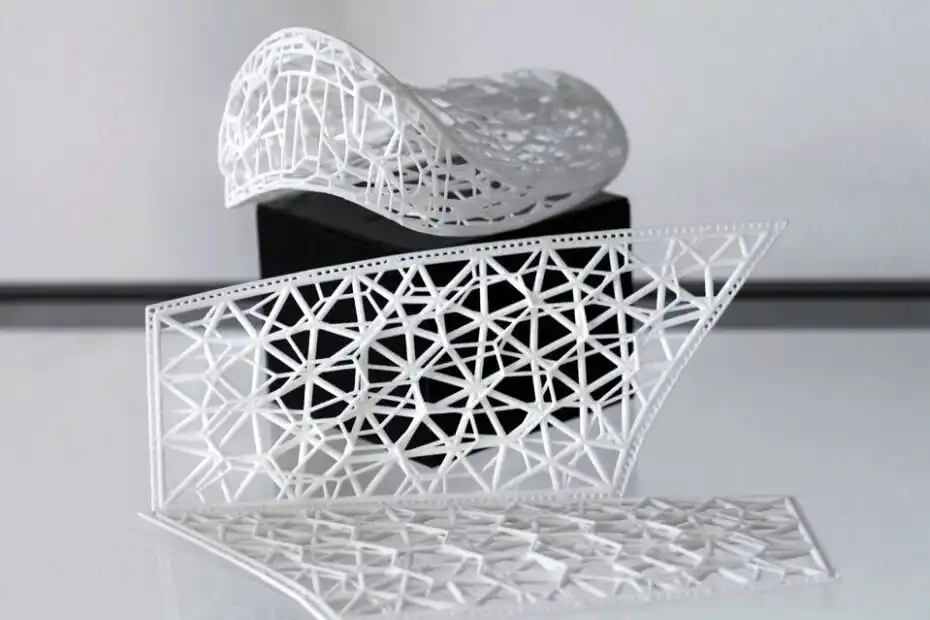

Industry 6: Architecture

The architecture industry has been increasingly leveraging the modern technology of 3D printing, specifically SLA 3D printing, to enhance design and production processes. SLA 3D printing, also known as stereolithography, is a technology that allows for the creation of complex, three-dimensional parts with a high degree of precision. This technology has found a significant application in the architecture industry, where it enables the production of customized architectural models.

The Role of SLA 3D Printing in Architecture

SLA 3D printing plays a crucial role in the architecture industry in several ways:

- Prototyping: SLA 3D printing enables rapid prototyping, allowing architects to test new designs and concepts before they are implemented on a larger scale. This can lead to significant cost savings by identifying and fixing design issues early in the development process.

- Customization: SLA 3D printing allows for the creation of customized architectural models, providing architects with the flexibility to meet the unique needs of each project. This can lead to increased client satisfaction and loyalty.

- Cost-Effective: Compared to traditional architectural model manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for architects who are looking to reduce costs without compromising on quality.

Examples of SLA 3D Printed Architecture Parts

SLA 3D printing has been used to create a variety of architectural parts, including:

- Building Models: SLA 3D printing has been used to create customized building models, providing architects with the flexibility to meet the unique needs of each project. These models can be used to showcase a realistic, miniature version of the final result.

- Interior Detail Models: SLA 3D printing has been used to create customized interior detail models, providing architects with the flexibility to meet the unique needs of each project. These models can be used to reveal more information about the design.

- Complex Structures: SLA 3D printing has been used to create customized complex structures, providing architects with the flexibility to meet the unique needs of each project. These structures can be used to showcase the final result of the project.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the architecture industry. By enabling the creation of customized architectural models and providing a cost-effective solution, SLA 3D printing is helping to improve architectural design processes and reduce costs. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the architecture industry.

Industry 7: Fashion

The fashion industry is increasingly leveraging the modern technology of 3D printing, specifically SLA 3D printing, to enhance design and production processes. SLA 3D printing, also known as stereolithography, is a technology that allows for the creation of complex, three-dimensional parts with a high degree of precision. This technology has found a significant application in the fashion industry, where it enables the production of customized fashion items .

The Role of SLA 3D Printing in Fashion

SLA 3D printing plays a crucial role in the fashion industry in several ways:

- Prototyping: SLA 3D printing enables rapid prototyping, allowing fashion designers to test new designs and concepts before they are implemented on a larger scale. This can lead to significant cost savings by identifying and fixing design issues early in the development process.

- Customization: SLA 3D printing allows for the creation of customized fashion items, providing fashion designers with the flexibility to meet the unique needs of each customer. This can lead to increased customer satisfaction and loyalty.

- Cost-Effective: Compared to traditional fashion manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for fashion designers who are looking to reduce costs without compromising on quality.

- Sustainability: SLA 3D printing is more environmentally friendly than traditional fashion manufacturing methods. Being a form of additive manufacturing, 3D printing only uses the exact amount of material required for the fashion item being 3D printed. This economical approach to 3D printing ensures no waste of fabric, as could be the case with traditional fashion making methods.

Examples of SLA 3D Printed Fashion Parts

SLA 3D printing has been used to create a variety of fashion parts, including:

- Dresses: SLA 3D printing has been used to create customized dresses, providing fashion designers with the flexibility to meet the unique needs of each customer. These dresses can be used to showcase a realistic, miniature version of the final result.

- Shoes: SLA 3D printing has been used to create customized shoes, providing fashion designers with the flexibility to meet the unique needs of each customer. These shoes can be used to showcase a realistic, miniature version of the final result.

- Accessories: SLA 3D printing has been used to create customized accessories, providing fashion designers with the flexibility to meet the unique needs of each customer. These accessories can be used to showcase a realistic, miniature version of the final result.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the fashion industry. By enabling the creation of customized fashion items and providing a cost-effective and environmentally friendly solution, SLA 3D printing is helping to improve fashion design processes and reduce costs. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the fashion industry.

Industry 8: Education

The education sector is increasingly leveraging the modern technology of 3D printing, specifically SLA 3D printing, to enhance learning and research processes. SLA 3D printing, also known as stereolithography, is a technology that allows for the creation of complex, three-dimensional parts with a high degree of precision. This technology has found a significant application in the education sector, where it enables the production of customized educational aids.

The Role of SLA 3D Printing in Education

SLA 3D printing plays a crucial role in the education sector in several ways:

- Prototyping: SLA 3D printing enables rapid prototyping, allowing educators to test new educational aids and concepts before they are implemented on a larger scale. This can lead to significant cost savings by identifying and fixing design issues early in the development process.

- Customization: SLA 3D printing allows for the creation of customized educational aids, providing educators with the flexibility to meet the unique needs of each student. This can lead to increased student engagement and satisfaction.

- Cost-Effective: Compared to traditional educational aid manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for educators who are looking to reduce costs without compromising on quality.

- Engagement: SLA 3D printing can help improve student engagement and participation in the learning process. By allowing students to physically manipulate ready-printed teaching aids or by designing tools themselves, 3D printing offers a hands-on approach to learning that can be more effective than traditional methods.

Examples of SLA 3D Printed Educational Aids

SLA 3D printing has been used to create a variety of educational aids, including:

- Teaching Aids: SLA 3D printing has been used to create customized teaching aids, providing educators with the flexibility to meet the unique needs of each student. These aids can be used to showcase a realistic, miniature version of the final result.

- Scientific Models: SLA 3D printing has been used to create customized scientific models, providing educators with the flexibility to meet the unique needs of each student. These models can be used to showcase a realistic, miniature version of the final result.

- Artistic Pieces: SLA 3D printing has been used to create customized artistic pieces, providing educators with the flexibility to meet the unique needs of each student. These pieces can be used to showcase a realistic, miniature version of the final result.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the education sector. By enabling the creation of customized educational aids and providing a cost-effective solution, SLA 3D printing is helping to improve educational processes and reduce costs. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the education sector.

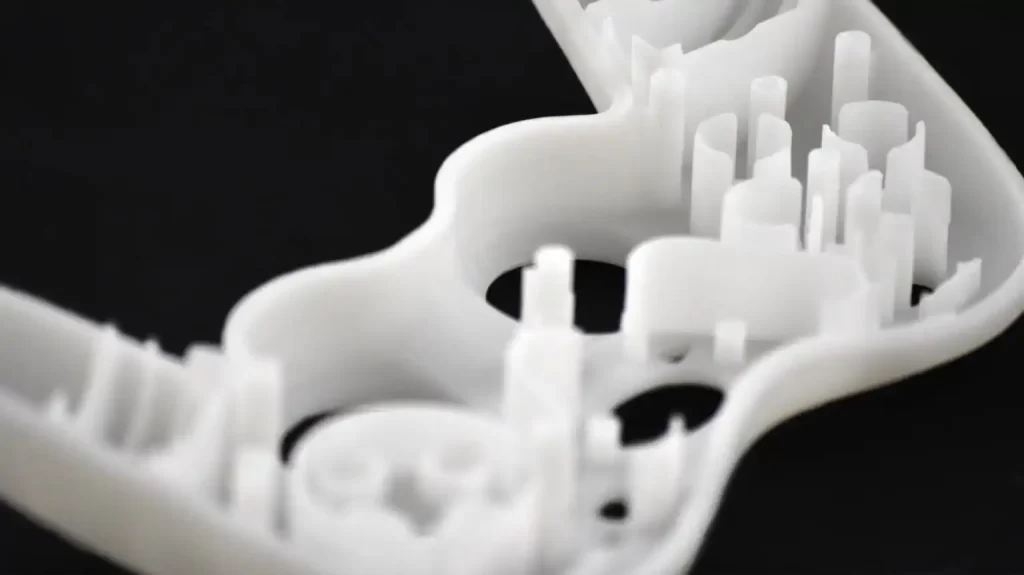

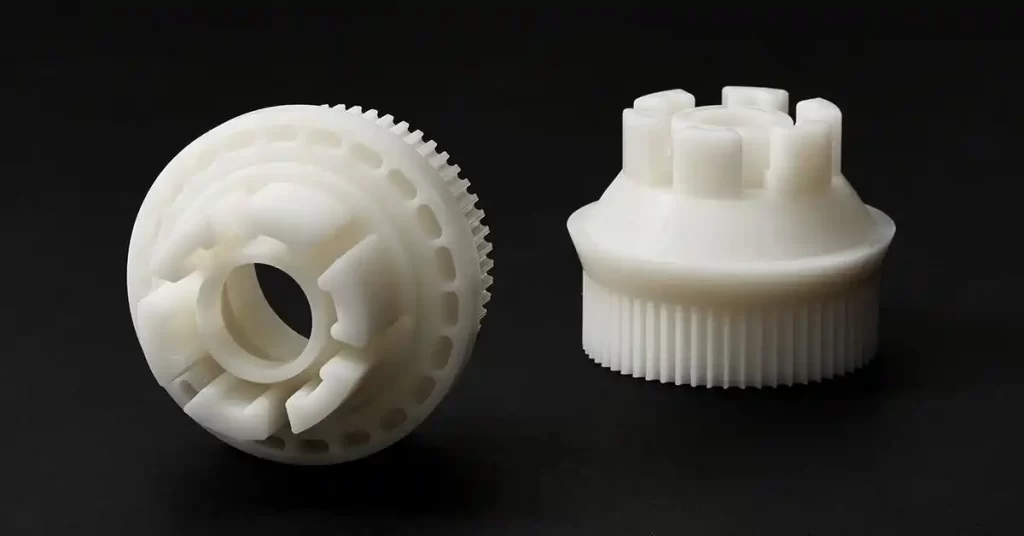

Industry 9: Manufacturing

The manufacturing industry is the backbone of many economies worldwide, responsible for the production of a wide range of goods. From small-scale artisanal products to large-scale industrial machinery, manufacturing processes are constantly evolving to improve efficiency, reduce costs, and meet the ever-changing demands of consumers. One such evolution is the use of SLA 3D printing.

SLA 3D printing, also known as stereolithography, is a technology that is transforming the manufacturing industry. It allows for the creation of complex, three-dimensional parts with a high degree of precision, making it an ideal solution for manufacturers looking to improve their production processes and reduce costs.

The Role of SLA 3D Printing in Manufacturing

SLA 3D printing plays a crucial role in the manufacturing industry in several ways:

- Prototyping: SLA 3D printing enables rapid prototyping, allowing manufacturers to test new designs and concepts before they are implemented on a larger scale. This can lead to significant cost savings by identifying and fixing design issues early in the development process.

- Customization: SLA 3D printing allows for the creation of customized parts, providing manufacturers with the flexibility to meet the unique needs of each customer. This can lead to increased customer satisfaction and loyalty.

- Cost-Effective: Compared to traditional manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for manufacturers who are looking to reduce costs without compromising on quality.

Examples of SLA 3D Printed Manufacturing Parts

SLA 3D printing has been used to create a variety of manufacturing parts, including:

- Engine Components: SLA 3D printing has been used to create customized engine components, providing manufacturers with the flexibility to meet the unique needs of each engine.

- Body Panels: SLA 3D printing has been used to create customized body panels, providing manufacturers with the flexibility to meet the unique needs of each product.

- Interior Components: SLA 3D printing has been used to create customized interior components, providing manufacturers with the flexibility to meet the unique needs of each product.

- Suspension Components: SLA 3D printing has been used to create customized suspension components, providing manufacturers with the flexibility to meet the unique needs of each product.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the manufacturing industry. By enabling the creation of customized parts and providing a cost-effective solution, SLA 3D printing is helping to improve production processes and reduce costs. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the manufacturing industry.

Industry 10: Entertainment

The entertainment industry is increasingly leveraging the modern technology of 3D printing, specifically SLA 3D printing, to enhance the creation of props, costumes, and special effects. SLA 3D printing, also known as stereolithography, is a technology that allows for the creation of complex, three-dimensional parts with a high degree of precision. This technology has found a significant application in the entertainment sector, where it enables the production of customized entertainment aids.

The Role of SLA 3D Printing in Entertainment

SLA 3D printing plays a crucial role in the entertainment sector in several ways:

- Prototyping: SLA 3D printing enables rapid prototyping, allowing entertainment designers to test new concepts before they are implemented on a larger scale. This can lead to significant cost savings by identifying and fixing design issues early in the development process.

- Customization: SLA 3D printing allows for the creation of customized entertainment aids, providing entertainment designers with the flexibility to meet the unique needs of each project. This can lead to increased engagement and satisfaction.

- Cost-Effective: Compared to traditional entertainment aid manufacturing methods, SLA 3D printing is a more cost-effective solution. This makes it a viable option for entertainment designers who are looking to reduce costs without compromising on quality.

- Engagement: SLA 3D printing can help improve audience engagement and participation in the entertainment process. By allowing audience members to physically manipulate ready-printed entertainment aids or by designing tools themselves, 3D printing offers a hands-on approach to entertainment that can be more effective than traditional methods.

Examples of SLA 3D Printed Entertainment Aids

SLA 3D printing has been used to create a variety of entertainment aids, including:

- Props: SLA 3D printing has been used to create customized props, providing entertainment designers with the flexibility to meet the unique needs of each project. These props can be used to showcase a realistic, miniature version of the final result.

- Costumes: SLA 3D printing has been used to create customized costumes, providing entertainment designers with the flexibility to meet the unique needs of each project. These costumes can be used to showcase a realistic, miniature version of the final result.

- Special Effects: SLA 3D printing has been used to create customized special effects, providing entertainment designers with the flexibility to meet the unique needs of each project. These effects can be used to showcase a realistic, miniature version of the final result.

In conclusion, SLA 3D printing is a powerful tool that is revolutionizing the entertainment sector. By enabling the creation of customized entertainment aids and providing a cost-effective solution, SLA 3D printing is helping to improve entertainment processes and reduce costs. As we continue to explore the potential of SLA 3D printing, we can expect to see even more innovative applications in the entertainment sector.

Conclusion

The Growing Importance and Bright Future of SLA 3D Printing

As we have explored, stereolithography (SLA) 3D printing is revolutionizing a diverse range of industries—from healthcare to entertainment. This technology empowers innovators across sectors to cost-effectively create highly accurate and customized products to meet specialized needs.

Recap: Industries Transformed by SLA 3D Printing

The versatility and precision of SLA 3D printing has proven beneficial for:

- Healthcare Creating customized prosthetics, implants, surgical guides

- Automotive Prototyping and production of intricate components

- Aerospace Building lightweight but durable flight-critical parts

- Dentistry Fabricating precision-fit dental implants and aligners

- Jewelry Enabling intricate, bespoke jewelry designs

- Architecture Crafting intricate scale models of architectural designs

- Fashion Printing customizable elements like shoe soles and textiles

- Education Engaging students by creating realistic educational models

- Manufacturing Building jigs, fixtures, assembly aids for factories

- Entertainment Developing collectible figures, movie props, miniatures

This table summarizes some key SLA 3D printing use cases by industry:

| Industry | Use Cases |

| Healthcare | Prosthetics, implants, guides |

| Automotive | Components, prototypes |

| Aerospace | Flight parts, prototypes |

| Dentistry | dental implants, aligners |

And the list goes on – SLA empowers innovation across sectors.

The Future Looks Bright for SLA 3D Printing

SLA 3D printing technology will only expand moving forward. Here are two trends to follow:

- Adoption in More Industries From textiles to marine applications, SLA will transform more sectors

- Materials Innovation New resins will enable more functionality like elasticity, conductivity, strength

The versatility and precision of SLA 3D printing positions it as a key manufacturing technology now and into the future across industries.