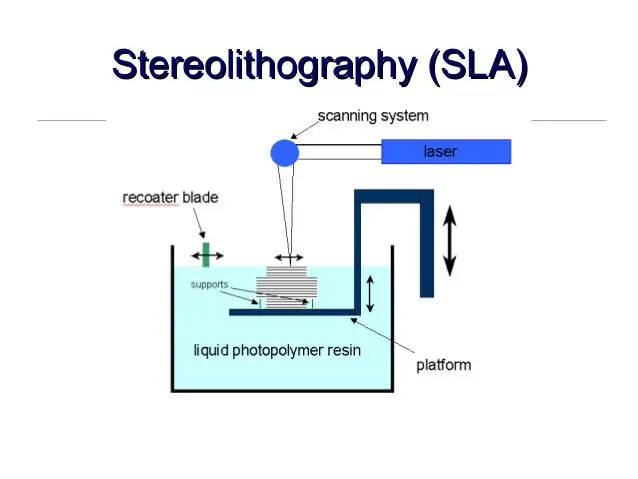

SLA, or Stereolithography, is an additive manufacturing process that utilizes a liquid resin and a UV laser to build objects layer by layer. This technology has revolutionized the prototyping process, allowing businesses to bring their concepts to life with incredible precision and efficiency. The advantages of SLA 3D printing for prototyping are numerous. It offers speed and efficiency, enabling rapid iteration and design improvements on the fly. The high precision and accuracy of SLA 3D printers allow designers and engineers to evaluate the functionality and aesthetics of a product before moving forward with mass production, minimizing the risk of costly errors or design flaws. The applications of SLA 3D printing span across various industries. From product design and development to medical and healthcare, automotive and aerospace, and even architecture and construction, SLA 3D printing is transforming the way we create and innovate.

When embarking on the journey of turning concepts into reality with SLA 3D printing, choosing the right service provider is crucial. Look for expertise, experience, and a deep understanding of the technology. Quality, precision, material selection, and excellent customer support are also essential factors to consider. In the following sections, we will delve deeper into the world of SLA 3D printing, providing design tips and insights to optimize your prototypes. So, let’s dive in and unlock the potential of prototyping for SLA 3D printing!

Understanding SLA 3D Printing

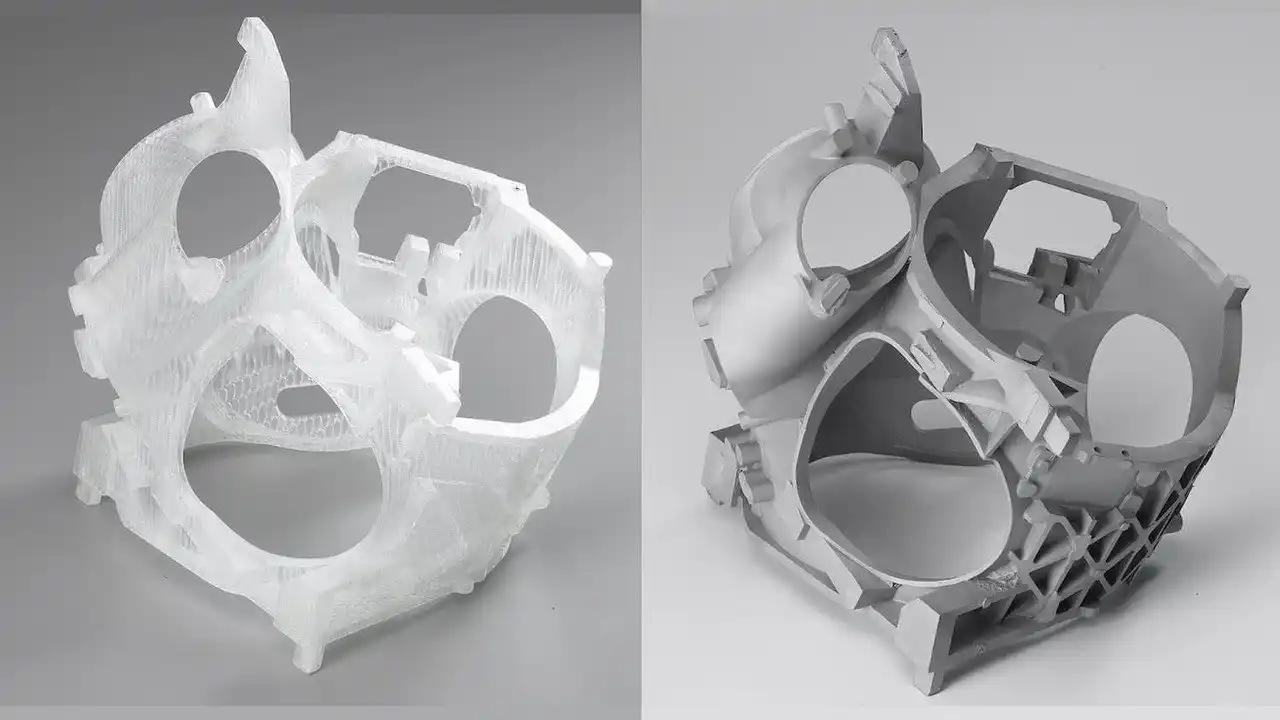

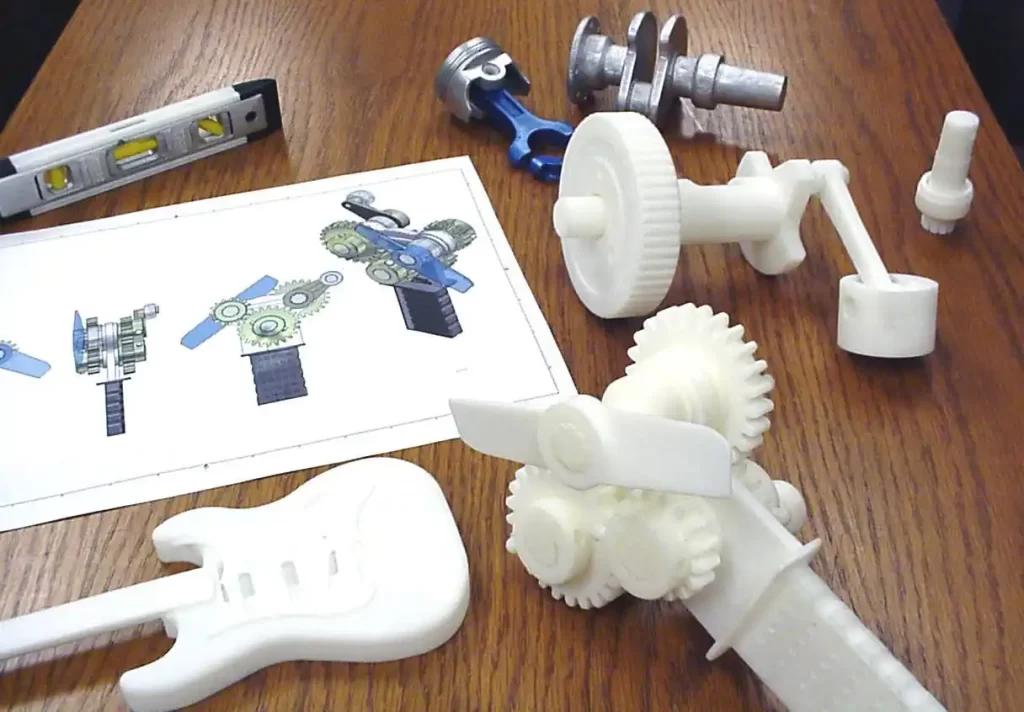

SLA 3D printing, also known as Stereolithography, is a revolutionary additive manufacturing process that utilizes a liquid resin cured by ultraviolet light to create three-dimensional objects layer by layer. Unlike traditional manufacturing methods, SLA 3D printing allows for the production of highly detailed and accurate prototypes with intricate geometries.

One of the key advantages of SLA 3D printing is its speed and efficiency. This technology enables rapid prototyping, significantly reducing the time it takes to transform an idea into a physical prototype. Businesses can iterate quickly and make design improvements on the fly, saving both time and money.

In addition to speed, SLA 3D printers can produce prototypes with exceptional precision and accuracy. This level of detail allows designers and engineers to thoroughly evaluate the functionality and aesthetics of a product before moving forward with mass production. By identifying design flaws early on, businesses can minimize the risk of costly errors or design flaws.

The automotive and aerospace sectors also benefit from SLA 3D printing. Engineers can create lightweight components with complex geometries, reducing overall weight and improving fuel efficiency. Additionally, functional prototypes can be developed to test aerodynamic performance, ergonomics, and overall functionality.When considering SLA 3D printing for prototyping, it is crucial to choose the right service provider. Look for a provider with expertise and experience in SLA 3D printing, a wide range of materials suitable for your specific application, and excellent customer support and communication. Overall, SLA 3D printing is a game-changer in the prototyping process, allowing businesses to bring their concepts to life with speed, precision, and versatility. By leveraging this advanced technology, companies can iterate quickly, reduce development costs, and gain a competitive edge in the market.

Advantages of SLA 3D Printing for Prototyping

SLA 3D printing offers numerous advantages for prototyping that set it apart from traditional manufacturing methods. With its speed, precision, and versatility, SLA 3D printing has revolutionized the way businesses bring their ideas to life.

One of the main advantages of SLA 3D printing is its speed and efficiency. Unlike traditional prototyping methods that involve lengthy lead times and complex processes, SLA 3D printing enables rapid prototyping. This means that businesses can quickly transform their concepts into physical prototypes, significantly reducing the time it takes to iterate and make design improvements. This not only saves time but also money, as it eliminates the need for costly tooling and lengthy production cycles.

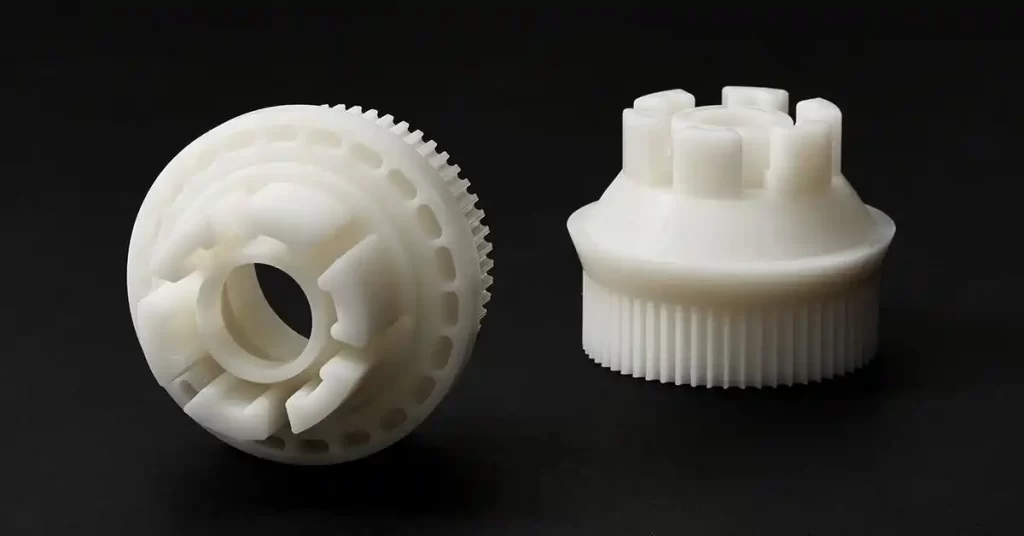

Another advantage of SLA 3D printing is its high precision and accuracy. SLA 3D printers can produce prototypes with exceptional detail, capturing even the finest features of a design. This level of precision allows designers and engineers to thoroughly evaluate the functionality and aesthetics of a product before moving forward with mass production. By identifying design flaws early on, businesses can minimize the risk of costly errors and ensure that their final product meets the highest standards of quality. In addition to speed and precision, SLA 3D printing offers a wide range of applications in various industries. From product design and development to medical and healthcare, automotive and aerospace, and architecture and construction, SLA 3D printing is transforming industries and enabling innovation like never before. It allows for the creation of functional prototypes, customized solutions, and detailed architectural models, all of which play a crucial role in the development and success of businesses.

When choosing an SLA 3D printing service provider, it is essential to consider factors such as their expertise and experience, the quality and precision of their output, the range of materials they offer, and their customer support and communication. By partnering with the right service provider, businesses can ensure that their prototyping needs are met with the highest level of professionalism and expertise. In conclusion, the advantages of SLA 3D printing for prototyping are clear. Its speed, precision, and versatility make it an invaluable tool for businesses looking to bring their concepts to life quickly and efficiently. By leveraging the power of SLA 3D printing, businesses can reduce development costs, iterate quickly, and gain a competitive edge in the market.

Applications of SLA 3D Printing in Various Industries

SLA 3D printing has revolutionized the prototyping process across various industries, enabling businesses to bring their ideas to life with speed and precision. Let’s explore some of the applications of SLA 3D printing in different sectors:

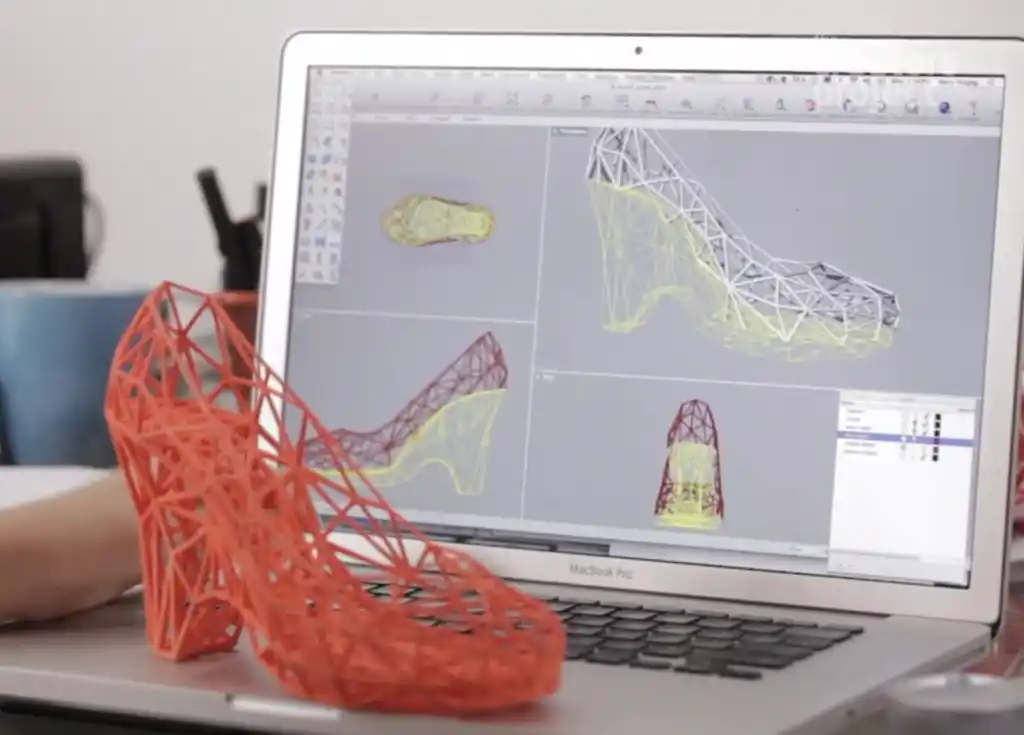

Product Design and Development

SLA 3D printing is a game-changer in the product development cycle. Designers can quickly transform their concepts into tangible prototypes, allowing for thorough testing and validation before committing to mass production. This iterative process helps identify design flaws early on, saving time and resources in the long run.

Medical and Healthcare

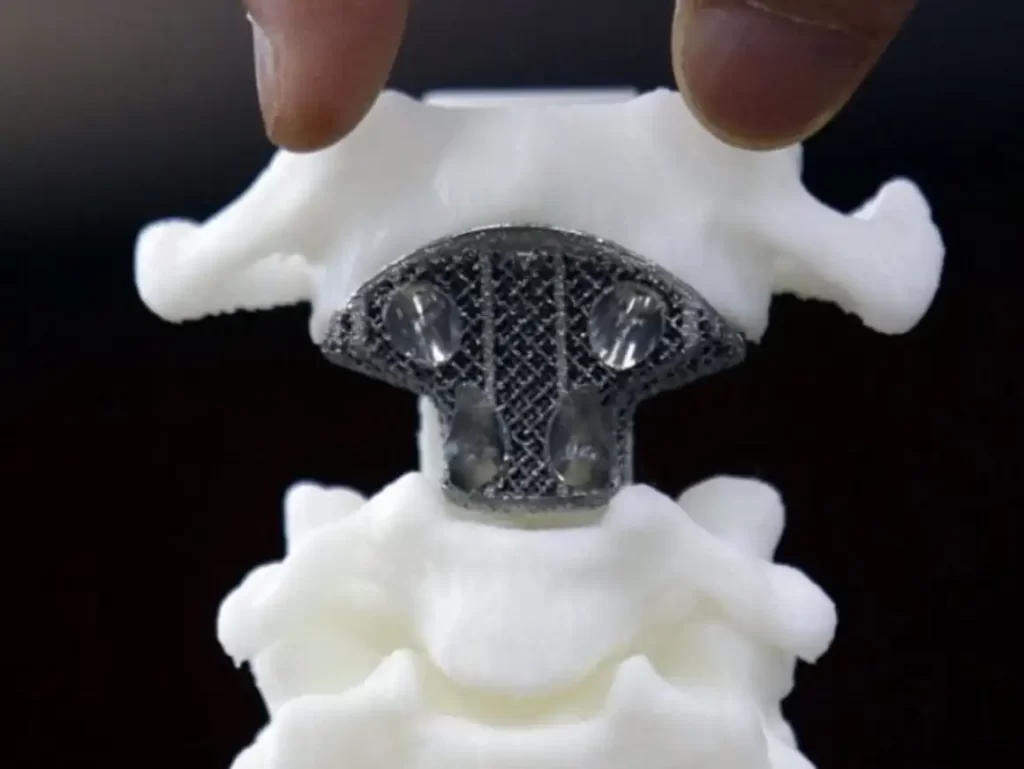

The medical industry heavily relies on accurate and customized solutions. SLA 3D printing enables the production of patient-specific anatomical models, surgical guides, prosthetics, and implants. This technology facilitates better surgical planning, reduces operating time, and improves patient outcomes.

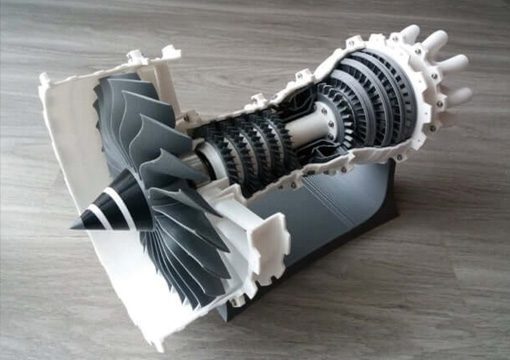

Automotive and Aerospace

SLA 3D printing plays a significant role in the automotive and aerospace sectors. It allows engineers to create lightweight components with complex geometries, reducing overall weight and improving fuel efficiency. Additionally, functional prototypes can be developed to test aerodynamic performance, ergonomics, and overall functionality.

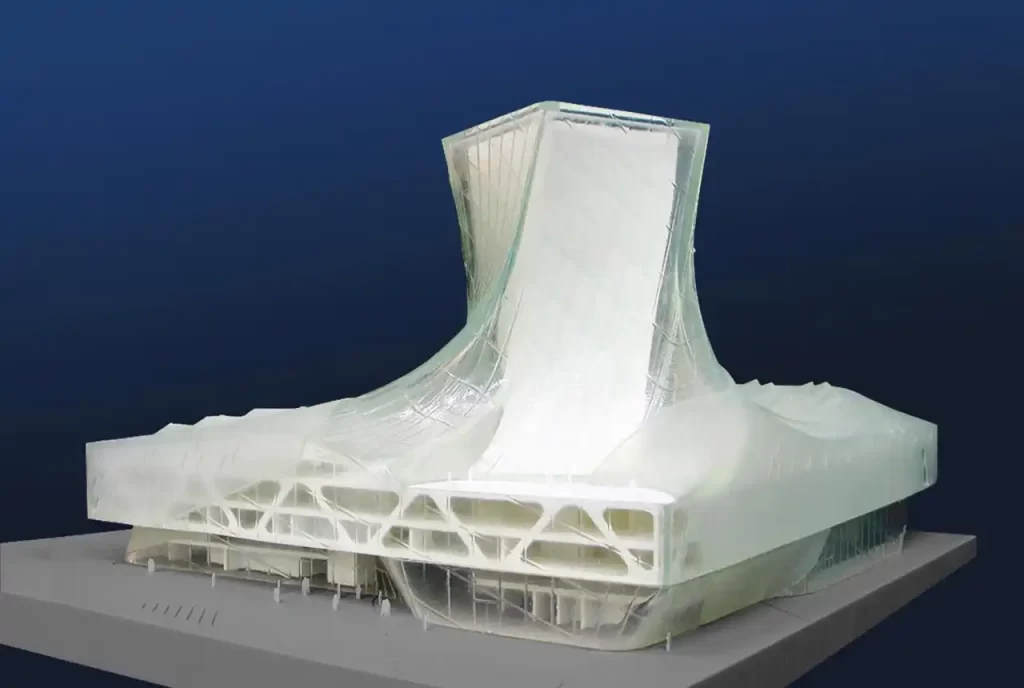

Architecture and Construction

Architects and designers leverage SLA 3D printing to create detailed architectural models, showcasing intricate facades, interior spaces, and landscaping. This technology aids in visualizing the final structure, identifying design flaws, and communicating ideas effectively to clients and stakeholders.

Consumer Electronics

SLA 3D printing enables rapid prototyping of devices, components, and enclosures before moving into mass production. It allows for quick design iterations, ensuring that the final product meets the desired specifications and aesthetics.

Art and Design

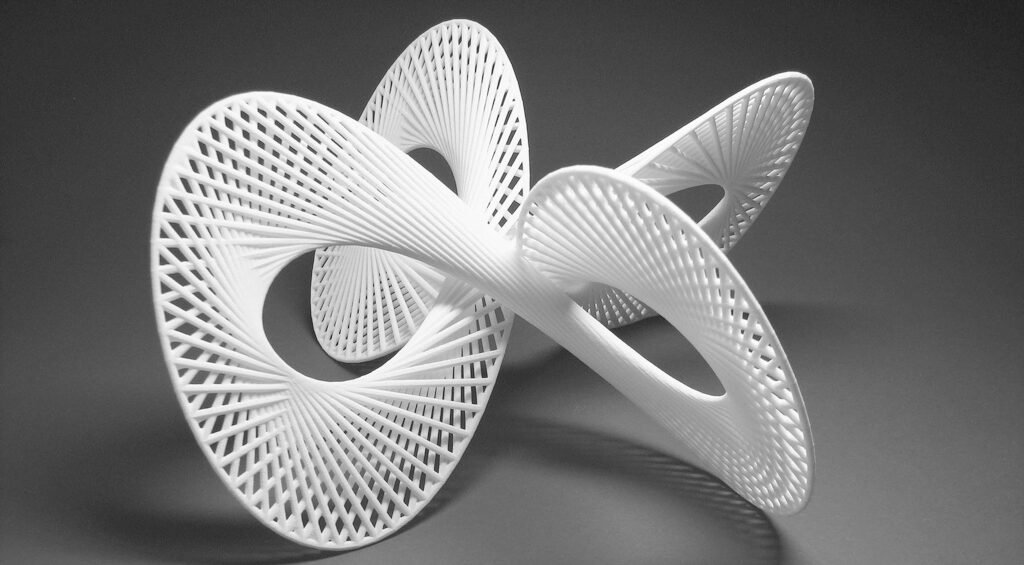

SLA 3D printing opens up new possibilities for artists and designers to create prototypes for fine art objects, jewelry, sculptural pieces, and more. It provides the flexibility to produce customized and limited-run design objects with intricate details and unique aesthetics.These are just a few examples of how SLA 3D printing is transforming industries and enabling innovation. The versatility and precision offered by this technology make it an invaluable tool for businesses looking to stay ahead of the competition and bring their ideas to life.

Choosing the Right SLA 3D Printing Service Provider

When it comes to prototyping with SLA 3D printing, choosing the right service provider is crucial. With the increasing popularity of SLA technology, there are numerous options available in the market. However, not all service providers are created equal, and it’s important to select one that meets your specific needs and requirements. First and foremost, consider the expertise and experience of the service provider. Look for a company that has a proven track record in SLA 3D printing and has successfully completed similar projects in the past. This will ensure that they have the necessary knowledge and skills to deliver high-quality prototypes.

Another important factor to consider is the range of materials offered by the service provider. Different projects may require different materials, and it’s essential to have a wide selection to choose from. Look for a service provider that offers a variety of resins with different properties, such as strength, flexibility, and heat resistance. Additionally, consider the level of customer support provided by the service provider. Prototyping projects often involve frequent communication and collaboration between the client and the provider. Make sure that the service provider is responsive and accessible, and that they are willing to work closely with you to achieve your desired results. Lastly, consider the cost and turnaround time offered by the service provider. While price shouldn’t be the only determining factor, it’s important to find a provider that offers competitive pricing without compromising on quality. Additionally, consider the turnaround time for your prototypes, as timely delivery is often crucial in the product development process. By carefully considering these factors, you can choose the right SLA 3D printing service provider that will meet your prototyping needs and help bring your ideas to life. Remember to thoroughly research and compare different providers to ensure you make an informed decision.

Design Tips for SLA 3D Printing

When it comes to designing for SLA 3D printing, there are several important factors to consider in order to optimize your prototypes for the best results. Here are some design tips to keep in mind:

Orientation

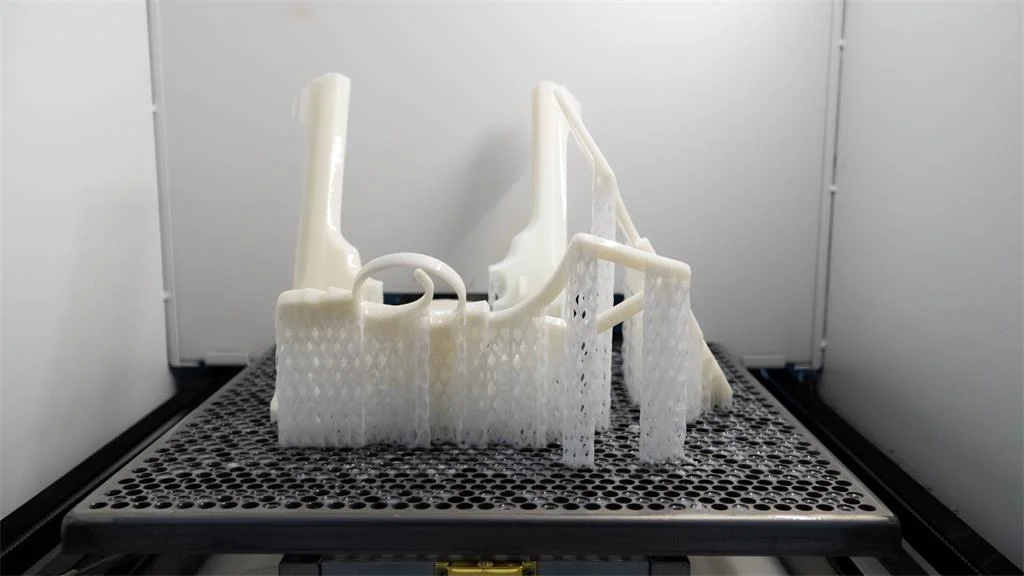

Consider the orientation of your model in the build volume. Avoid large overhangs and try to position your design in a way that minimizes the need for support structures. This will help to ensure successful printing and reduce the need for post-processing.

Wall Thickness

Ensure that the walls of your model are thick enough to maintain strength and durability. A wall thickness of at least 0.6mm is recommended, but be cautious of making them too thick, as this can lead to deformation and warping.

Support Structures

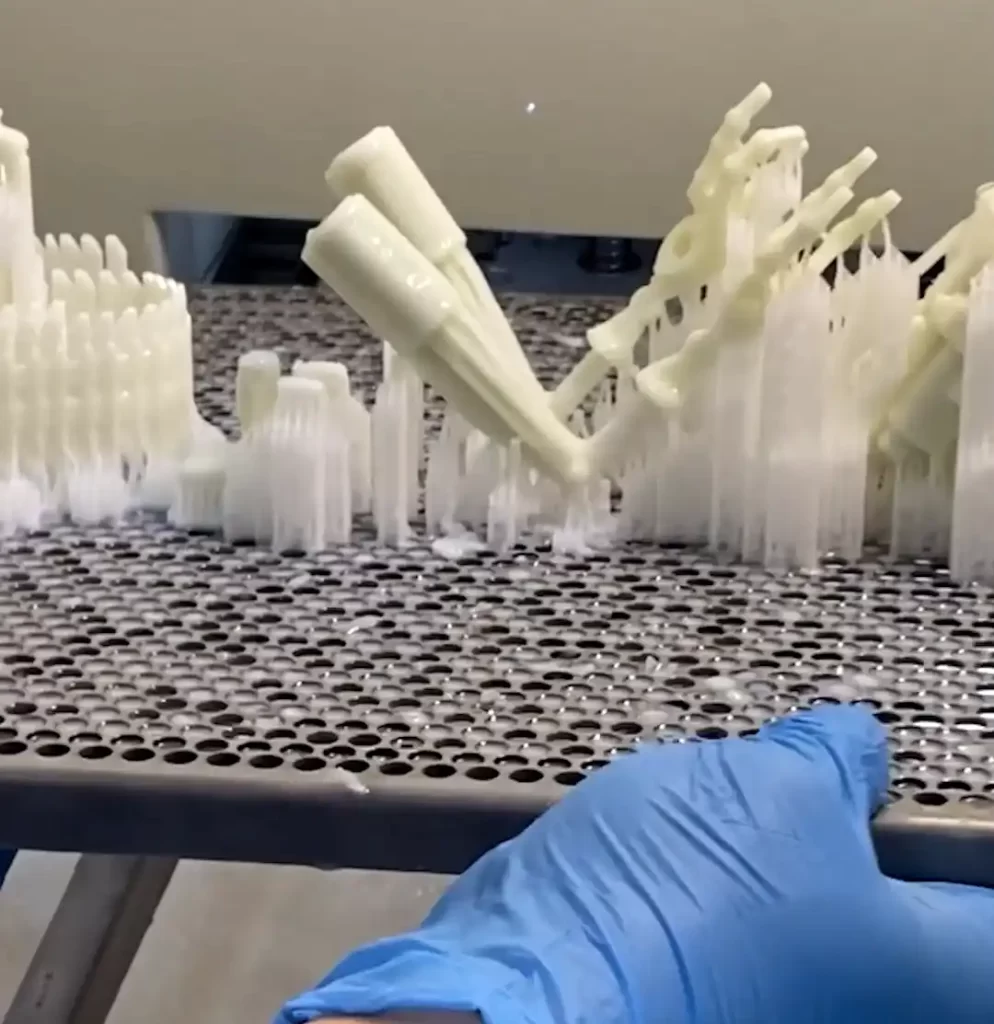

Supports are necessary for printing models with overhangs and complex geometries. Design your model in a way that allows for easy removal of supports, and consider incorporating non-removable supports where needed.

Hollowing

To save on material and reduce printing time, consider hollowing out your model. This can also help to reduce the weight of your prototype, making it easier to handle and transport.

Resolution

Take advantage of the high resolution capabilities of SLA 3D printers by designing models with intricate details. This technology can capture fine features and tight tolerances, so make sure to design accordingly.

Material Selection

Choose the appropriate material for your specific application. Different resins have different properties and are suited for different purposes. Consult with your SLA 3D printing service provider to select the best material for your project.

Post-Processing

Keep in mind that your model may require post-processing after printing. This can include removing support structures, sanding, and polishing. Design your model with enough room for these post-processing steps.By following these design tips, you can ensure that your prototypes are optimized for SLA 3D printing, resulting in high-quality, accurate, and functional models. Partnering with an experienced SLA 3D printing service provider can also help to ensure the success of your project.