Table of Contents

Introduction

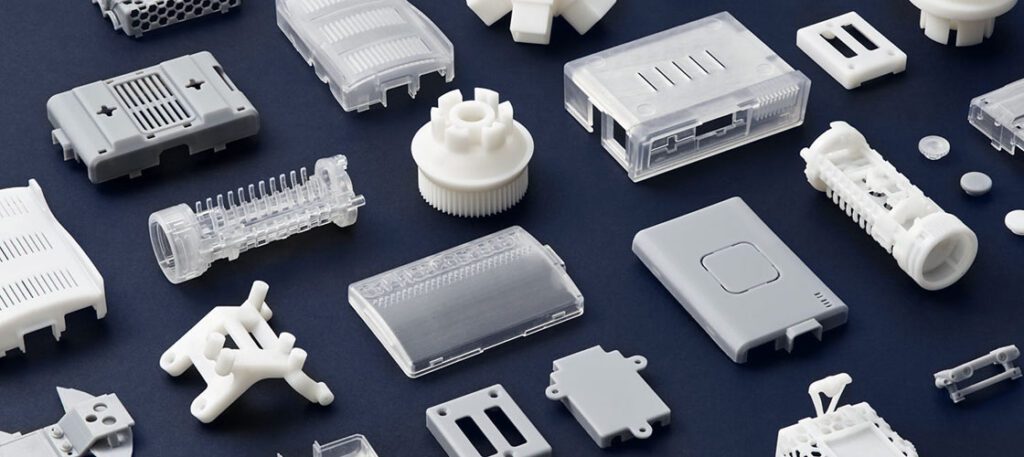

3D printing technology has rapidly grown in popularity and use across manufacturing industries in recent years. One of the most common and affordable 3D printing processes is known as stereolithography (SLA). SLA utilizes photopolymer resins and ultraviolet lasers to build parts layer-by-layer based on digital 3D model files. Compared to traditional manufacturing techniques like injection molding, machining, and casting, SLA 3D printing offers some unique advantages but also has some limitations to consider. Choosing the right manufacturing method depends on weighing the pros and cons for your specific business needs.

Advantages of SLA 3D Printing

SLA 3D printing provides several benefits that give businesses more design freedom and production flexibility compared to traditional manufacturing:

1. Rapid Prototyping

- SLA 3D printing enables very fast turnaround times for developing prototypes and concept models. Parts can be printed in hours or days rather than weeks.

- Businesses can quickly test and iterate through multiple design revisions and refinements.

- Low startup costs allow affordable production of prototypes in small batches or as one-off parts.

2. High Level of Detail and Accuracy

- The SLA process is capable of exceptionally high resolution and accuracy, often down to 25 microns or less.

- Complex geometries, intricate details, and smooth surface finishes can be produced.

- The need for manual finishing work or post-processing is reduced.

3. Customization and Personalization

- SLA printing allows complete flexibility and customization of product designs.

- Businesses can produce customized or personalized products tailored to individual customers.

- This can lead to greater customer satisfaction, brand loyalty, and increased perceived value.

4. Reduced Material Waste

- SLA printing is an additive process that uses only required resin amounts, reducing excess material waste.

- Businesses can print on-demand and reduce unnecessary inventory.

- The process has environmental benefits from less material consumption and waste.

5. Streamlined Production Process

- SLA 3D printing simplifies and streamlines the production process with fewer steps.

- No specialized tooling, molds, or machinery are required.

- Lead times can be reduced significantly, enabling faster delivery to market.

Disadvantages of SLA 3D Printing

While SLA offers many benefits, some downsides need consideration when deciding if it’s the right choice:

1. Limited Material Options

- The range of materials available for SLA is currently limited compared to traditional manufacturing.

- Material properties may not be suitable for all applications and uses.

- This can constrain product designs and functions.

2. Lower Strength and Durability

- SLA printed parts tend to have lower strength and durability than traditionally manufactured components.

- Products may have shorter lifespans or degrade faster under stress.

- Extensive testing and validation is required before use in demanding applications.

3. Higher Cost per Part

- For large production runs, SLA printed parts have a higher cost per unit compared to mass-manufactured items.

- Economies of scale are less achievable with additive printing.

- The total cost can outweigh the benefits beyond a certain production volume.

4. Limited Build Volume

- SLA printers have restricted build chamber sizes limiting the maximum part size.

- Larger components may require splitting into multiple sections for printing.

- This can introduce the need for assembly and joining after printing.

Traditional Manufacturing Methods

Traditional manufacturing techniques have stood the test of time and offer their own advantages:

1. Injection Molding

- Capable of high-volume production with very low cost per unit.

- Best suited for large production runs in the tens or hundreds of thousands.

- Produces strong and durable plastic parts with excellent mechanical properties.

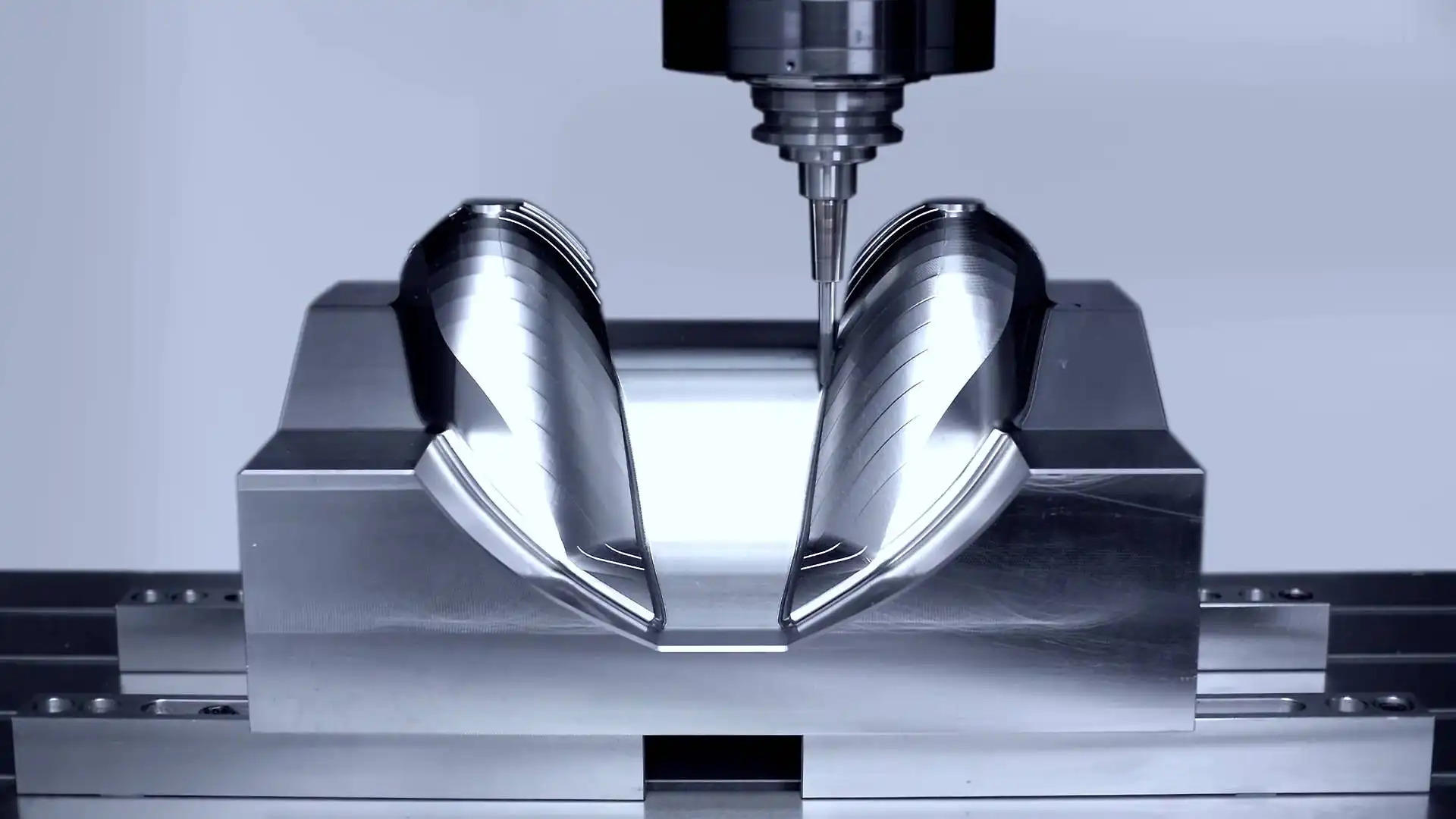

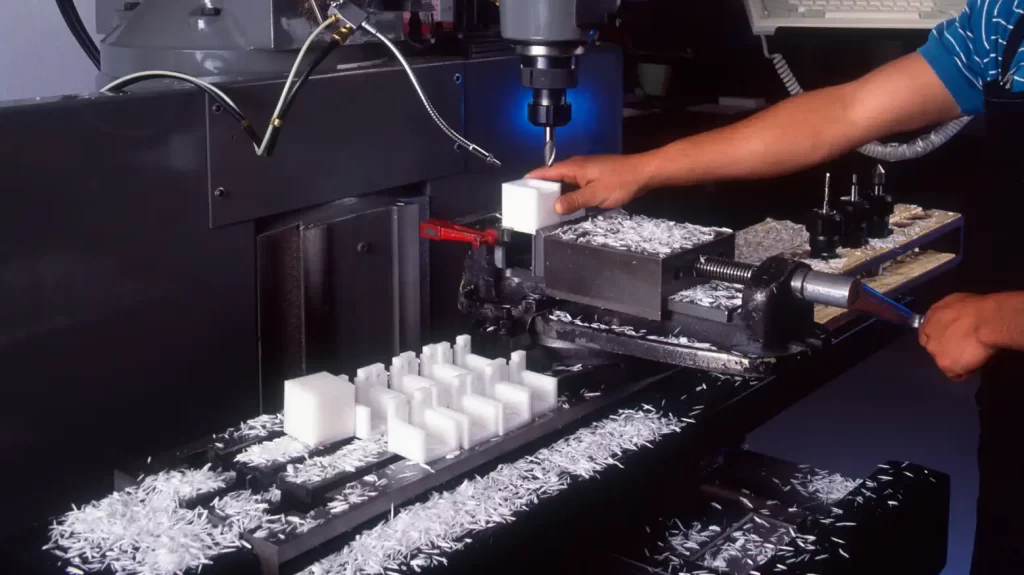

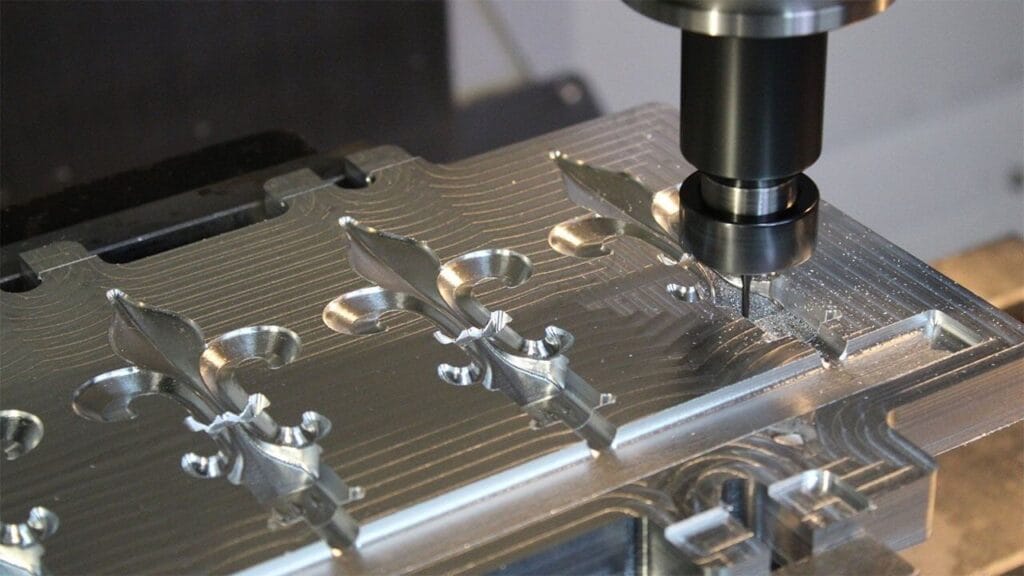

2. Machining

- Precision subtractive process for cutting and shaping metal or plastic stock materials.

- Allows high level of control over part dimensions, tolerances, and surface finish quality.

- Typically used for small to medium-sized production batches.

3. Casting

- Suitable for producing very large volumes of identical metal or plastic parts.

- Excellent consistency and low cost per unit for high-volume production.

- Capable of capturing highly detailed and complex geometries.

Conclusion

Determining if SLA 3D printing or traditional manufacturing methods are most appropriate depends on individual business factors like production volumes, part sizes, material requirements, and product life cycle phases. SLA offers greater design freedom and faster turnaround times, while traditional manufacturing is better suited for mass production runs. Businesses must weigh the trade-offs and merits of each solution for their specific needs and circumstances.

Comparing SLA 3D Printing and Traditional Manufacturing

| Criteria | SLA 3D Printing | Traditional Manufacturing |

|---|---|---|

| Production Speed | Fast for prototypes and small batches | Slow for tooling and setup, fast for high-volume production |

| Material Options | Limited selection of materials | Wide range of materials available |

| Product Details | High level of detail and accuracy possible | Limited by tooling and mold design |

| Customization | Easy to customize and personalize products | Difficult to customize without additional tooling costs |

| Material Waste | Minimal material waste due to additive process | High material waste due to subtractive process |

| Production Complexity | Simple production process with fewer steps | Multi-step process with tooling and mold development |

| Cost-Effectiveness | Cost-effective for small batches or one-offs | Cost-effective for high-volume production |