Imagine holding a smooth, intricately detailed object – a custom miniature, a precision medical model, or a functional prototype that rivals a finished product. Chances are, this marvel of modern manufacturing was created using Stereolithography (SLA) 3D printing. But how does this technology achieve such astonishing precision? Let’s unravel its core mysteries.

(A) The Essence of SLA 3D Printing

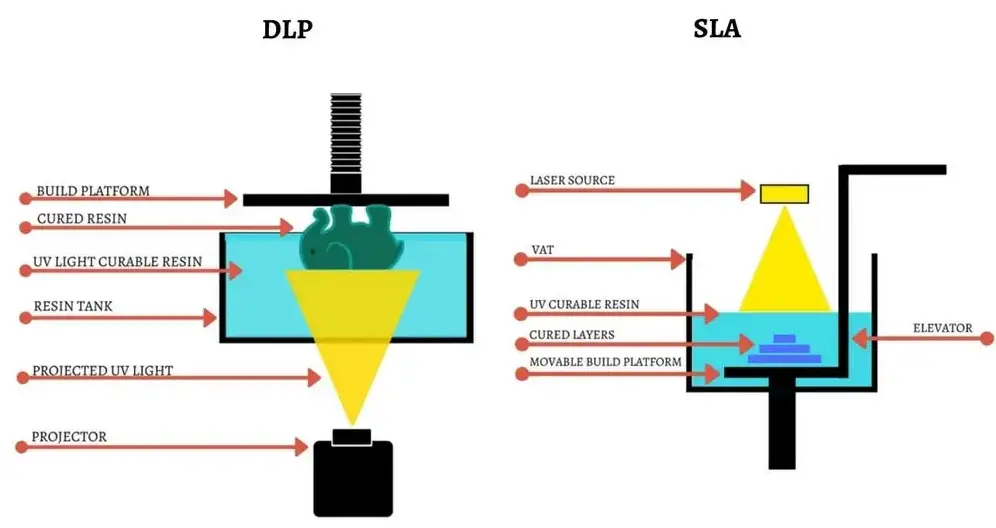

As a core additive manufacturing process, SLA falls under the category of vat polymerization. Its principle can be analogized to “painting with light in a liquid pool”: ultraviolet (UV) laser beams are used to cure liquid photopolymer resin layer by layer, constructing 3D entities. As the first commercialized 3D printing technology, SLA remains renowned for its “ultra-high precision, extremely smooth surfaces, and ultra-fine details,” making it ideal for scenarios demanding aesthetic perfection or structural complexity.

(B) Laser Precision: The Core Competence of SLA

SLA’s unique charm stems not only from its photopolymerization principle but also from the “micro-control magic” of its laser system. This precisely calibrated UV light acts like a sculpting tool in the micro-world, achieving micron-level positioning in liquid resin. How does it transform liquid resin into high-fidelity solids? How does focused energy create sharp edges and smooth curves? This article will reveal how laser precision becomes the technological soul of SLA from the dimensions of optical principles, mechanical control, and material reactions.

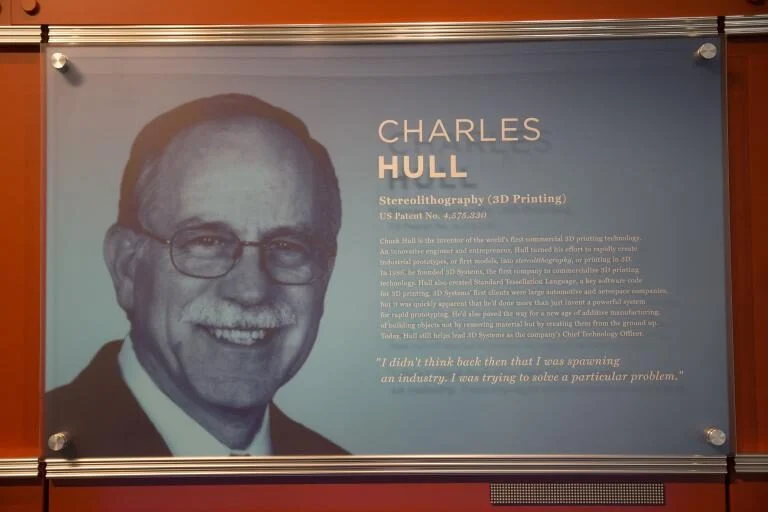

(C) The Evolution of SLA Technology

The technical origins of SLA can be traced back to the early 1980s when Japanese scholar Kodama first proposed the concept of “layered manufacturing with photosensitive polymers.” In 1984, American entrepreneur Chuck Hull patented the technology and named it “Stereolithography.” He co-founded 3D Systems in 1986, launching the first commercial SLA equipment and officially inaugurating the 3D printing industry. From early large-scale and expensive industrial machines to today’s accessible desktop models, technological iterations have continuously enhanced SLA’s precision and usability, making it a standard tool in studios and R&D institutions.

This article provides a comprehensive analysis of the SLA technology system: from core principles spanning the resin vat to finished products, the precise mechanisms of laser systems, the characteristics of diverse resin materials, and end-to-end workflow management, to comparisons of technical advantages/disadvantages, application scenarios, and future trends. Whether you are an engineer, designer, or industry enthusiast, you will gain deep insights into SLA’s operational logic and why laser precision makes it a benchmark technology in manufacturing.

II. Core Working Principles of SLA: The Precision Transformation from Liquid to Solid

The magic of SLA lies in the “light-liquid-solid” trio that transforms digital models into physical entities. This process is not magic but a symphony of optics, chemistry, and mechanical engineering.

(A) Photopolymerization: The Curing Code of Liquid Resin

The chemical core of SLA is the “photopolymerization reaction”:

- Role of Light: UV light (typically 355nm or 405nm wavelength) acts as a trigger to activate photoinitiator molecules in the resin.

- Molecular Chain Construction: Photoinitiators generate free radicals upon absorbing light energy, initiating cross-linking of monomer and oligomer chains, transforming liquid resin into solid polymers.

This process is akin to “light-controlled solidifying ink” – areas irradiated by the laser cure into shape, while unexposed areas remain liquid, ultimately stacking into 3D entities layer by layer.

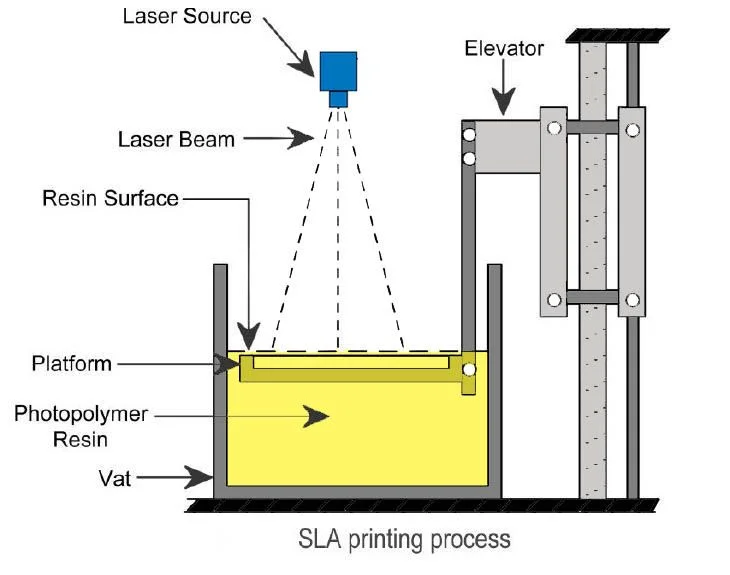

(B) Key Hardware Components: A Meticulously Coordinated Mechanical Ensemble

SLA printers rely on the seamless collaboration of five core components to achieve precise output:

| Component Name | Function Description | Factors Influencing Precision |

| Resin Vat | Holds liquid resin, with a transparent bottom (for bottom-up models) for light transmission. | Cleanliness affects light transmittance; contamination causes curing unevenness. |

| Build Platform | Supports the printed part, moving layer by layer in the Z-axis direction. | Z-axis movement precision directly determines layer thickness uniformity and overall dimensional accuracy. |

| Laser System | Emits UV laser beams with a focused spot diameter of 80-150μm (smaller in some models). | Spot size determines XY-axis resolution; power stability affects curing depth. |

| Galvo System | Rapidly reflects laser beams to achieve intra-layer trajectory scanning. | Mirror response speed and positioning accuracy determine detail fidelity; scanning delays cause contour deviations. |

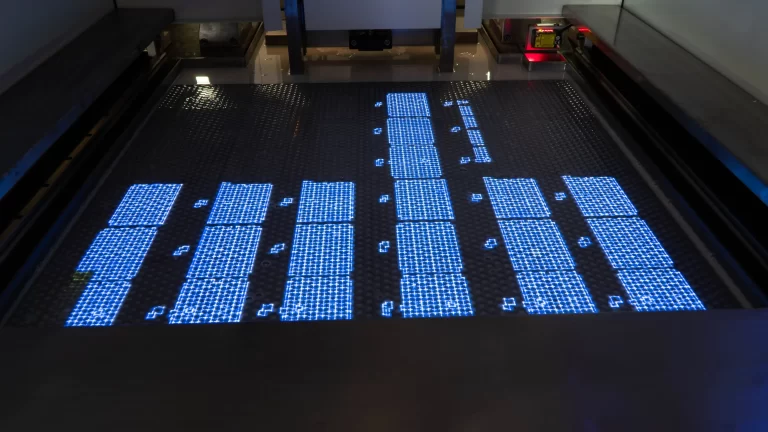

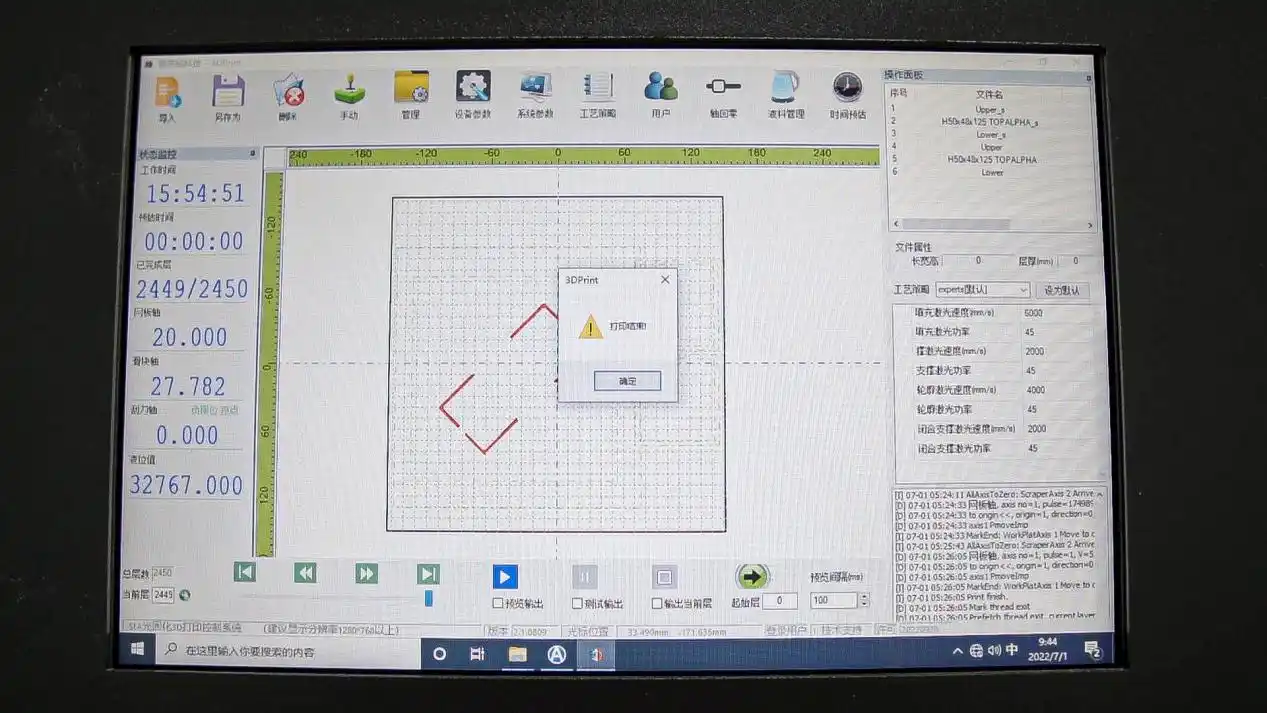

(C) The Printing Workflow: The Physicalization Journey of Digital Models

The SLA printing process can be divided into three main stages, each requiring meticulous control:

1. Digital Model Preprocessing: Digital Preparation from Design to Slicing

- Model Creation: Design via CAD software (e.g., Fusion 360) or obtain through 3D scanning in STL/OBJ format.

- Slicing: Use slicing software (e.g., PreForm) to cut the model into horizontal layers of 25-100μm thickness, generating laser scanning paths.

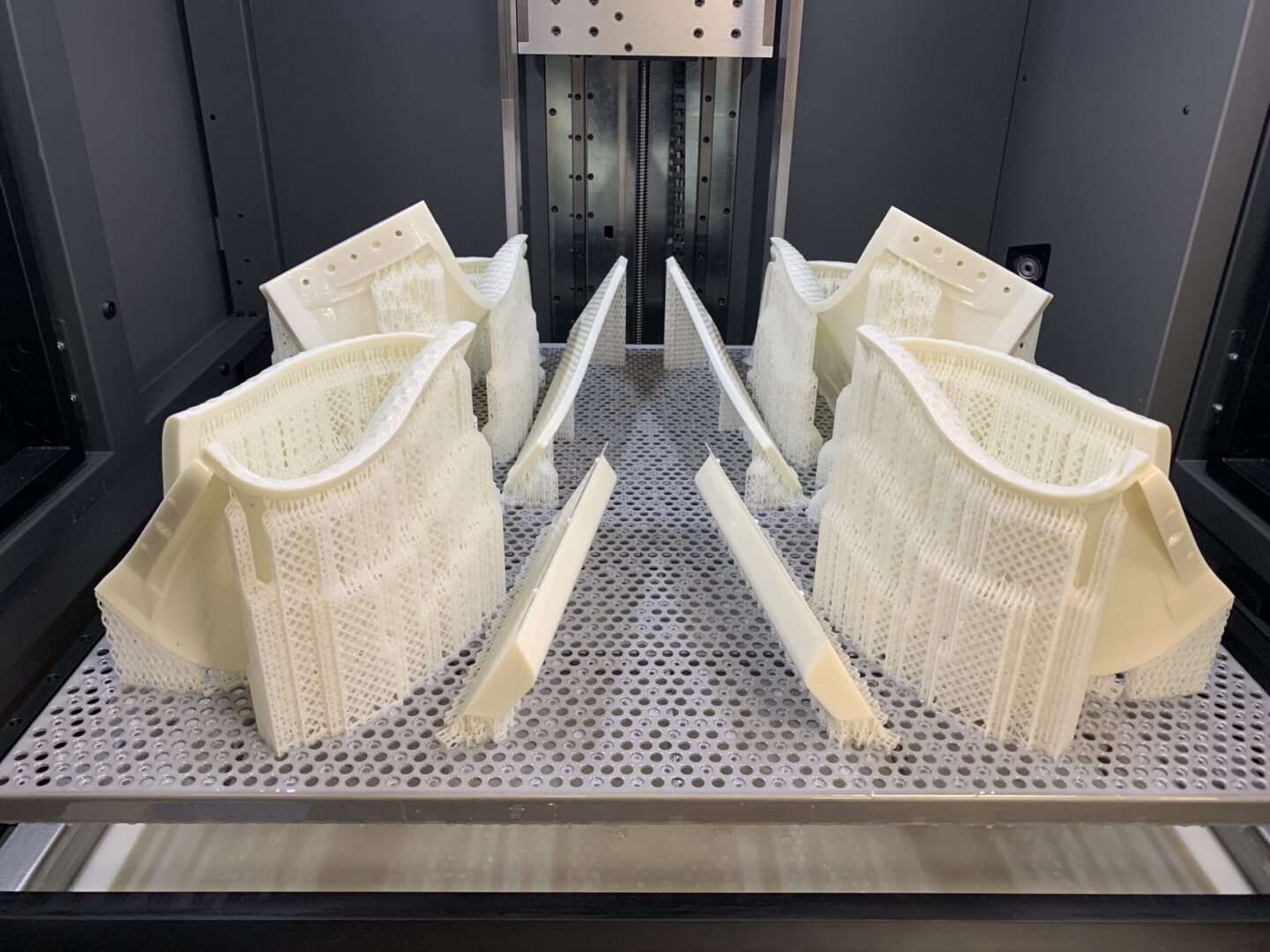

- Support Design: Automatically generate lattice support structures to fix overhangs and distribute peeling forces, with support contact points typically 0.2-0.5mm in diameter.

- Orientation Optimization: Tilt the model to reduce overhang area; for example, a 45° overhang reduces support needs by 50%.

2. Layer-by-Layer Printing: The Micro Dance of Light and Resin

- Layer Thickness Control: Bottom-up models control layer thickness via the gap between the platform and vat bottom (typically 50-200μm); top-down models rely on blade coating precision.

- Laser Scanning: The galvo system deflects at thousands of times per second, guiding laser beams to scan according to sliced contours, with single-point exposure times of 0.5-5 seconds.

- Peeling Mechanism: After each layer cures in bottom-up models, the platform must overcome 1-5N peeling force to lift; flexible FEP films reduce peeling resistance by 30%.

- Resin Leveling: Utilize resin viscosity (typically 500-2000mPa·s) for natural gap filling or force leveling via blades (top-down models).

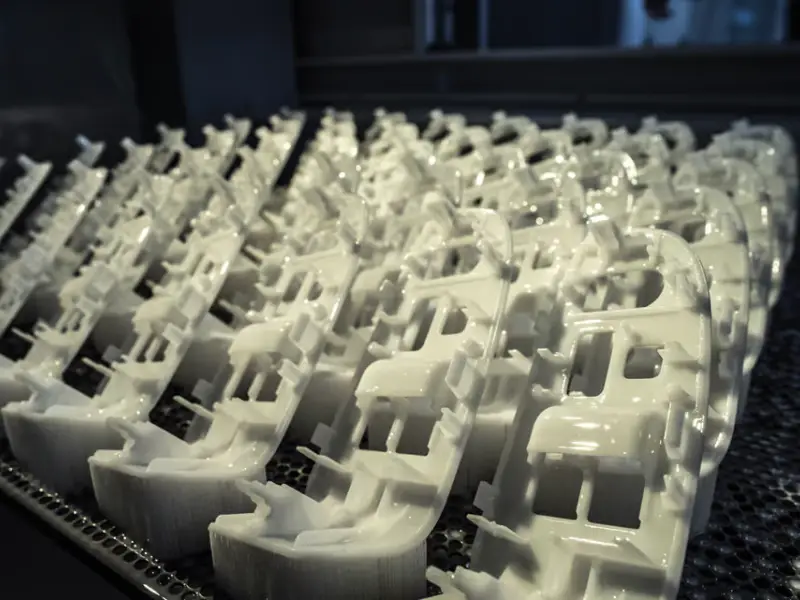

3. Post-Processing: The Transformation from Semi-finished to Finished Products

- Washing: Soak in 95% isopropyl alcohol (IPA) for 5-15 minutes; ultrasonic cleaning improves complex inner cavity cleaning efficiency.

- Curing: Expose to a UV curing chamber (405nm LED, 50-200mW/cm² power) for 10-30 minutes; high-temperature curing (60-80°C) enhances heat resistance by 20%.

- Support Removal: Cut supports with flush cutters; sand residual contact points with 400# sandpaper to reduce surface roughness from Ra 3.2μm to Ra 1.6μm.

(D) Machine Classification: Bottom-Up vs. Top-Down

Based on light source position and printing direction, SLA is divided into two main categories:

- Bottom-Up Models (Mainstream Solution)

- Advantages: Less resin usage (only needs to cover model height); compact equipment suitable for desktop applications.

- Challenges: Peeling forces may fracture thin-walled structures, requiring optimization via flexible vat bottoms or dynamic peeling technologies (e.g., Formlabs LFS™).

- Top-Down Models (Industrial Solution)

- Advantages: No peeling force limitations, suitable for large-scale parts with 30% fewer support requirements.

- Challenges: Requires full vat resin filling, high material costs; blade systems increase mechanical complexity. (Zongheng3D DM Series DLP Printers)

III. Laser System: The Core Engine of SLA Precision

When marveling at SLA parts’ micron-level details, we are witnessing the precise control capabilities of the laser system. The core competitiveness of this “optical sculptor” stems from the ultimate optimization of wavelength, spot size, and scanning.

(A) Laser Characteristics: Precise Matching of Wavelength and Energy

- Wavelength Selection: 355nm UV light suits traditional epoxy resins, while 405nm is compatible with new low-toxicity resins; a ±5nm wavelength deviation reduces curing efficiency by 15%.

- Power Control: Typical power ranges from 50-200mW; ±10% power fluctuations cause ±20μm curing depth deviations, requiring real-time calibration via closed-loop feedback systems.

- Energy Density: Calculated as (power/spot area) × exposure time, with a recommended range of 50-150mJ/cm²; insufficient energy causes under-curing, while excessive energy leads to over-burning.

(B) Galvo System: The Nanometer-Level Steering Wheel for Laser Beams

- Working Principle: Dual-axis galvos (X/Y axes) are driven by voice coil motors, with mirror deflection angles of ±25° and positioning accuracy of 0.1mrad.

- Scanning Speed: Maximum speed可达5000mm/s, but high speeds require compensation for “galvo delay” (typically 50-100μs); otherwise, contour deviations occur.

- Precision Limit: With a 50μm spot, 70μm linewidth printing is achievable, equivalent to engraving a QR code on a fingernail.

(C) Spot Size: The Deciding Factor for Detail Resolution

- Physical Definition: The diameter of the focused laser beam directly determines the minimum feature size. An 80μm spot can print 0.1mm apertures, while a 150μm spot suits features above 0.2mm.

- Diffraction Limit: The theoretical minimum spot ≈ 1.22 × wavelength × focal length/aperture; in practice, aspherical lenses can approach 80% of this theoretical value.

- Speed-Precision Tradeoff: Small spots (e.g., 50μm) increase scanning time by 2-3 times for complex structures compared to large spots (150μm), requiring demand-based selection.

(D) System Integration: Multidimensional Factors Influencing Precision

| Influence Dimension | Specific Elements | Optimization Goals |

| Optical System | Lens aberration, mirror flatness, optical path calibration | Spot roundness >90%, energy uniformity >95% |

| Mechanical System | Galvo installation rigidity, Z-axis guide straightness, platform | Vibration amplitude <20μm, Z-axis repeat positioning accuracy ±5μm |

| Environmental Control | Temperature (23±2℃), humidity (<50%RH), air flow disturbance | Every 1℃ temperature fluctuation changes resin viscosity by 5-10% |

| Software Compensation | Nonlinear distortion correction, dynamic laser power adjustment, over-curing compensation algorithms | Feature size error <±100μm, surface deviation <0.1° |

IV. SLA Resin Systems: The Performance Magic from Liquid to Solid

SLA’s versatility largely stems from the richness of its resin materials. These “liquid magics” achieve wide-ranging performance through molecular formulation design, from flexible rubber to high-temperature engineering plastics.

(A) Resin Composition Analysis: Four Core Elements

- Monomers/Oligomers: Provide basic mechanical properties; acrylic monomers give rigidity, while polyurethane oligomers provide elasticity.

- Photoinitiators: Absorb light energy to initiate polymerization, commonly Irgacure series at 1-5% concentration; insufficient content reduces curing depth.

- Fillers: Glass fibers (enhance rigidity), ceramic powders (improve heat resistance), carbon black (impart conductivity), with filling ratios of 5-30%.

- Additives: Flow agents (improve surface tension), inhibitors (extend shelf life), color pastes (enable color customization).

(B) Resin Classification and Typical Applications

| Category | Representative Model | Key Performance Indicators | Typical Application Scenarios |

| Standard Resin | Formlabs Grey Resin | Tensile strength 40MPa, surface roughness Ra 1.6μm | Concept models, jewelry prototypes, educational aids |

| High-Strength Resin | BASF Ultracure® Rigid | Flexural modulus 3000MPa, heat deflection temperature 80℃ | Mechanical fixtures, snap-fit structures, low-volume functional parts |

| Flexible Resin | Anycubic Elastic Resin | Elongation at break 300%, Shore hardness 50A | Seals, shock pads, wearable devices |

| High-Temperature Resin | DSM Somos® PerFORM | Heat deflection temperature 150℃, UL94 V-0 flammability rating | Engine component prototypes, injection molds |

| Biocompatible Resin | Asiga Pro 40 | ISO 10993 certification, cytotoxicity < Grade 1 | Dental models, surgical guides, implant prototypes |

(C) Material Selection Guidelines

- Mechanical Requirements: Choose high-strength resins (e.g., nylon-based) for load-bearing structures; flexible resins (e.g., TPU-based) for dynamic loads.

- Environmental Requirements: Select anti-yellowing resins (with UV stabilizers) for outdoor applications; ceramic-filled resins for high-temperature scenarios.

- Process Requirements: Low-viscosity resins (<800mPa·s) for fast printing; high-sensitivity resins (exposure time <1s) for fine details.

- Cost Control: Use general-purpose resins ($30-$50/kg) for experimental projects; specialized resins ($100-$300/kg) for industrial applications.

(D) Safety Operation Specifications

- Protective Equipment: Wear nitrile gloves and goggles; equip operating areas with fume hoods to ensure VOC concentration <50ppm.

- Storage Requirements: Store in dark, sealed containers at 15-25℃ with a typical shelf life of 6-12 months; expired resin curing efficiency drops by 40%.

- Waste Disposal: Uncured resin must be collected in specialized containers, cured under UV light, and disposed of as general solid waste; do not pour down drains.

V. Workflow Optimization: Efficiency Enhancement from Design to Finished Product

Successful SLA printing relies not only on equipment and materials but also on meticulous management of the entire workflow. Below are optimization strategies for key steps:

(A) Design Guidelines: Design for SLA Manufacturability

- Overhang Angle: Maximum unsupported overhang angle 45° (resin vat direction); add 20% more support density for every 10° increase.

- Wall Thickness Design: Minimum wall thickness 0.3mm (standard resin), 0.5mm (filled resin); add stiffeners for thin-walled structures.

- Hollow Design: Reduces material consumption by 30-50%, but requires ≥1mm drainage holes with ≤10mm spacing to prevent air pockets.

- Feature Size: Minimum aperture 0.5mm, minimum boss 0.3mm, minimum text engraving depth ≥0.1mm.

(B) Slicing Parameter Tuning

- Layer Thickness Selection: High-precision mode (25μm) for curved parts; standard mode (50μm) to balance speed and quality; draft mode (100μm) for rapid prototyping.

- Support Density: Support point spacing 1-3mm in overhang areas; island structures require circular support enclosures with 0.2-0.4mm contact points.

- Bottom Exposure: Initial 3-5 layers with 2-3× standard layer exposure time (e.g., 5s for standard 2s layers) to ensure platform adhesion.

(C) Post-Processing Optimization

- Cleaning Efficiency: Two-step cleaning (first tank removes 80% resin, second tank fine cleans) reduces residual resin <0.1%; ultrasonic cleaning cuts time by 50%.

- Curing Profile: Stepwise curing (e.g., 365nm pre-curing for 10 minutes + 405nm main curing for 20 minutes) increases cross-linking by 15% and reduces internal stress.

- Surface Treatment: Vapor polishing reduces surface roughness from Ra 3.2μm to Ra 0.8μm; electroplating imparts metallic texture and conductivity.

VI. Technical Advantages and Limitations: SLA’s Core Competitiveness and Constraints

(A) Core Advantages

| Advantage Dimension | Specific Performance | Application Scenarios Example |

| Leading Precision | Dimensional tolerance ±0.1mm, minimum feature 0.1mm, surface deviation <0.1° | Medical implant prototypes, aerospace sensor housings |

| Excellent Surface | As-printed roughness Ra 1.6-3.2μm, close to injection-molded parts; suitable for direct aesthetic verification | Consumer electronics casings, art sculptures, jewelry |

| Material Diversity | Covers 50+ commercial resins including rigid, flexible, high-temperature, transparent, biocompatible | Flexible robot grippers, high-temperature engine components, dental guides |

| Design Freedom | Capable of printing complex internal cavities, hollow structures, 0.2mm thin walls, breaking through traditional machining limitations | Microfluidic chips, lattice structure heat sinks |

(B) Main Limitations

resins have 70-80% strength of traditional injection-molded parts.

- Size Restrictions: Desktop models max out at ~300×300×400mm; large parts require split printing and assembly.

VII. Application Scenarios: Industry Innovation Driven by Laser Precision

(A) Medical Field: The Cornerstone of Precision Medicine

- Orthopedic Implants: Customized titanium alloy prosthesis prototypes via topological optimization; SLA-printed resin models enable lost-wax casting with <0.1mm dimensional error.

- Bioprinting: Vascularized tissue engineering scaffolds printed with biocompatible resins (e.g., PEGDA), pore sizes controlled at 100-500μm to promote cell adhesion.

(B) Aerospace: Breakthroughs in Lightweighting and Complex Structures

- Turbine Blade Prototypes: High-temperature resin (HDT 180℃) prints cooling channel structures, replacing 50+ CNC-machined parts for 40% weight reduction.

- Satellite Components: 0.3mm-thick carbon fiber-reinforced resin radomes with Ra<1.6μm surface roughness, meeting RF signal transmission requirements.

(C) Automotive Industry: From Prototyping to Low-Volume Production

- Interior Development: Flexible resin (Shore 70A) prints steering wheel grip prototypes, cutting tactile testing cycles from 2 weeks to 24 hours.

- New Energy Sector: Fuel cell flow field plates with complex serpentine channels, dimensional accuracy ±0.08mm, 60% reduction in gas leakage.

(D) Consumer Electronics: Rapid Market Response

- Mobile Phone Casing Sampling: Transparent resin prototypes completed from CAD in 48 hours for optical and ergonomic evaluation, 70% cost reduction vs. traditional CNC.

- Wearable Devices: 0.15mm-thick flexible circuit board carriers with integrated sensor interfaces, enabling true “electronic skin” prototypes.

(E) Art and Cultural Innovation: The Ultimate in Detail Rendering

- Cultural Relic Replication: 0.02mm-precision replication of bronze ware patterns via 3D scanning + SLA, used for museum exhibitions and academic research.

- Trendy toy design: 0.5mm hollow hair strands, 2mm transparent eyeballs, and other micro-structures, disrupting traditional hand-carving efficiency with 80% shorter production cycles.

VIII. Troubleshooting: Common Issues and Solutions

| Fault Symptom | Possible Cause | Resolution Strategy |

| First Layer Adhesion Failure | Uneven platform leveling / insufficient bottom exposure | Re-calibrate platform (gap 0.1-0.2mm); increase bottom exposure to 2.5× standard layers |

| Inter-Layer Delamination | Excessive peeling force / high resin viscosity | Replace with flexible FEP vat bottom; add 5% diluent (within manufacturer limits) |

| Blurred Details | (Laser power decay / spot deviation) | Calibrate laser power (±5% tolerance); re-focus spot to design size (<10% error) |

| Sticky Surface | Incomplete cleaning / insufficient curing energy | Extend cleaning to 10 minutes; increase curing dose by 20% (e.g., from 200mJ/cm² to 240mJ/cm²) |

| Hollow Part Explosion | Missing drainage holes / internal resin residue | Design ≥1mm drainage holes; flush internal cavities with a syringe post-print |

IX. Future Trends: The Evolutionary Trajectory of SLA Technology

(A) Hardware Innovations: Faster, More Precise, Larger-Scale

- Multi-Laser Arrays: Industrial devices will feature 4-8 laser beams for simultaneous scanning, 3-5× faster printing suitable for large automotive body panels.

- Dynamic Spot Technology: Adjustable focus lenses enable dynamic spot size switching (20-200μm), using small spots for complex details and large spots for bulk filling, 40% overall efficiency gain.

- VacuumResin Vats: Negative pressure environments reduce bubble formation; ultrasonic stirring improves resin uniformity to 99.5%, ideal for microfluidic chip precision.

(B) Material Revolution: Performance Breakthroughs and Sustainability

- Self-Healing Resins: Reversible covalent bond chemistry enables UV-triggered crack self-healing, extending service life 3-5×.

- Plant-Based Resins: Bio-based resins derived from soybean oil and pine resin will account for 30%, with >60% degradability meeting environmental regulations.

- 4D Printing Materials: Light-responsive shape-memory resins enable “print flat, trigger 3D,” applicable for aerospace deployable mechanisms.

(C) Software and Automation: AI-Driven Smart Production

- Generative Design Integration: AI algorithms automatically optimize support structures based on mechanical simulations, reducing support material use by 50% while increasing print success rates to 98%.

- Fully Automated Workflows: Unmanned production lines integrating printing, cleaning, curing, and quality inspection will popularize, achieving 24/7 operation with vision inspection systems.

- Digital Twin Technology: Real-time monitoring of 20+ parameters (resin temperature, laser power) enables predictive maintenance, reducing equipment failure rates by 70%.

(D) Application Expansion: From Prototyping to Mass Production

- Direct Digital Manufacturing (DDM): High-precision SLA devices for low-volume production (50-500 units), such as customized medical devices and high-end watch components, 30% lower cost than injection molding.

- Hybrid Manufacturing Systems: Integration of SLA with CNC and electroplating enables “print-machine-coat” one-stop processing, cutting complex part lead times from 4 weeks to 72 hours.

X. Selection Guide: How to Choose the Right SLA Equipment

(A) Core Parameter Comparison

| Dimension | Desktop (e.g., Formlabs Form 3) | Industrial (e.g., 3D Systems ProJet 8000) |

| Build Volume | 145×145×185mm | 381×381×457mm |

| Spot/Pixel Size | 75μm laser spot | 50μm DLP projection pixel |

| Layer Thickness | 25-100μm | 16-100μm |

| Resin Compatibility | 10+ official resins | 50+ industrial resins |

| Price Range | $$3,500$$10,000 | $$100,000$$500,000 |

(B) Selection Decision Tree

- Application Scenario:

- Concept Prototyping/Education → Choose desktop DLP/MSLA (e.g., Anycubic Photon M3) for low cost and ease of use.

- Functional Testing/Low-Volume Production → Industrial laser SLA (e.g., EnvisionTEC Perfactory) for precision and stability.

- Precision Requirements:

- Features >0.3mm → Desktop devices (±0.15mm precision) suffice.

- Micron-level precision (e.g., medical guides) → Industrial devices (±0.05mm precision) with temperature control.

- Material Needs:

- Standard resins → Open-system devices (e.g., Phrozen Sonic Mini 4K) for third-party material support.

- Special resins (biocompatible/high-temperature) → Closed systems (e.g., Asiga MAX) with manufacturer-optimized parameters.

(C) Total Cost of Ownership (TCO) Analysis

- Equipment Depreciation: Annual depreciation $1,000-$3,000 for desktops; $20,000-$100,000 for industrials.

- Consumable Costs: 20-100L resin annually; $1,000-$5,000 for desktops, $20,000-$100,000 for industrials.

- Maintenance Expenses: Galvo calibration ($500-$2,000/year); resin vat replacement ($200-$800/200 hours).

Conclusion: The Manufacturing Future Defined by Laser Precision

Since the first commercial device in 1984, SLA has remained driven by “laser precision,” pushing manufacturing toward “precision, complexity, and personalization.” Whether micron-scale medical stents or aerospace complex inner cavities, they all rely on the precise coordination of light, mechanics, and materials.

In the future, with multi-laser technology, intelligent materials, and automated production lines, SLA will transcend “rapid prototyping” to become a core “rapid manufacturing” technology – evolving from laboratory precision instruments to mainstream manufacturing standards. For engineers and designers, mastering SLA principles and applications means holding the key to the future of manufacturing.

In this era where “anything can be printed,” SLA writes new frontiers for manufacturing with laser beams – and we are witnessing the golden age of this precision revolution.