What is SLA 3D Printing?

SLA 3D printing, short for Stereolithography Apparatus, is a revolutionary technology that uses a process called photopolymerization to create three-dimensional objects. It works by using a laser to selectively cure liquid resin, layer by layer, to form the desired object. This technology offers several advantages over traditional manufacturing methods, such as the ability to create complex geometries and intricate details. SLA 3D printing has found applications in various industries, including healthcare, automotive, and jewelry.

Advantages of SLA 3D Printing

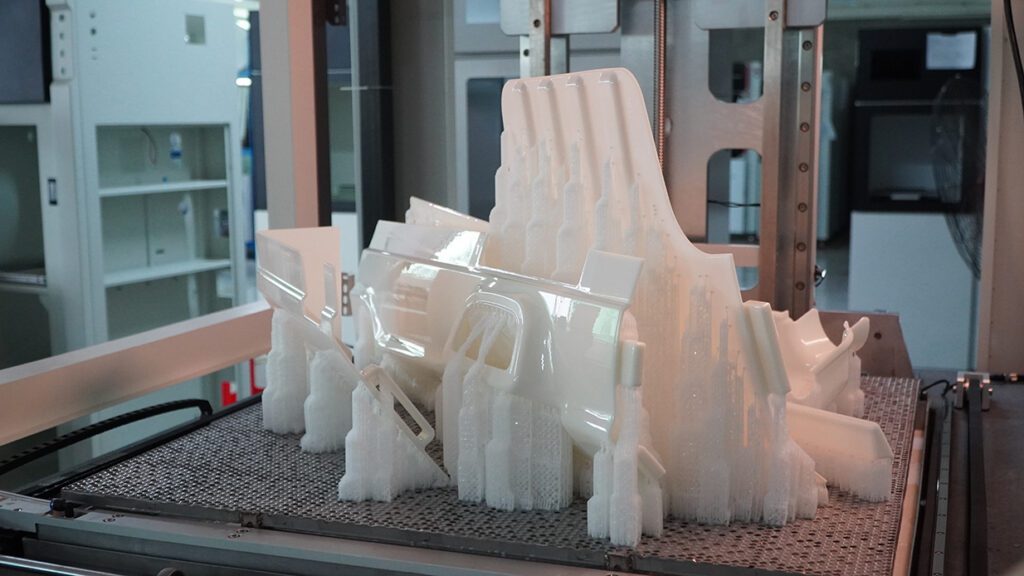

SLA 3D printing offers several advantages over traditional manufacturing methods. Firstly, it allows for the creation of highly detailed and complex designs that are difficult to achieve with other techniques. Secondly, SLA 3D printing enables rapid prototyping, reducing the time and cost associated with traditional manufacturing processes. Additionally, SLA 3D printing allows for the use of a wide range of materials, including resins that can simulate the properties of various finished products. Lastly, SLA 3D printing offers greater design freedom, allowing for the creation of intricate geometries and intricate internal structures. Overall, SLA 3D printing is revolutionizing technology applications by providing faster, more cost-effective, and highly customizable manufacturing solutions.

Applications of SLA 3D Printing

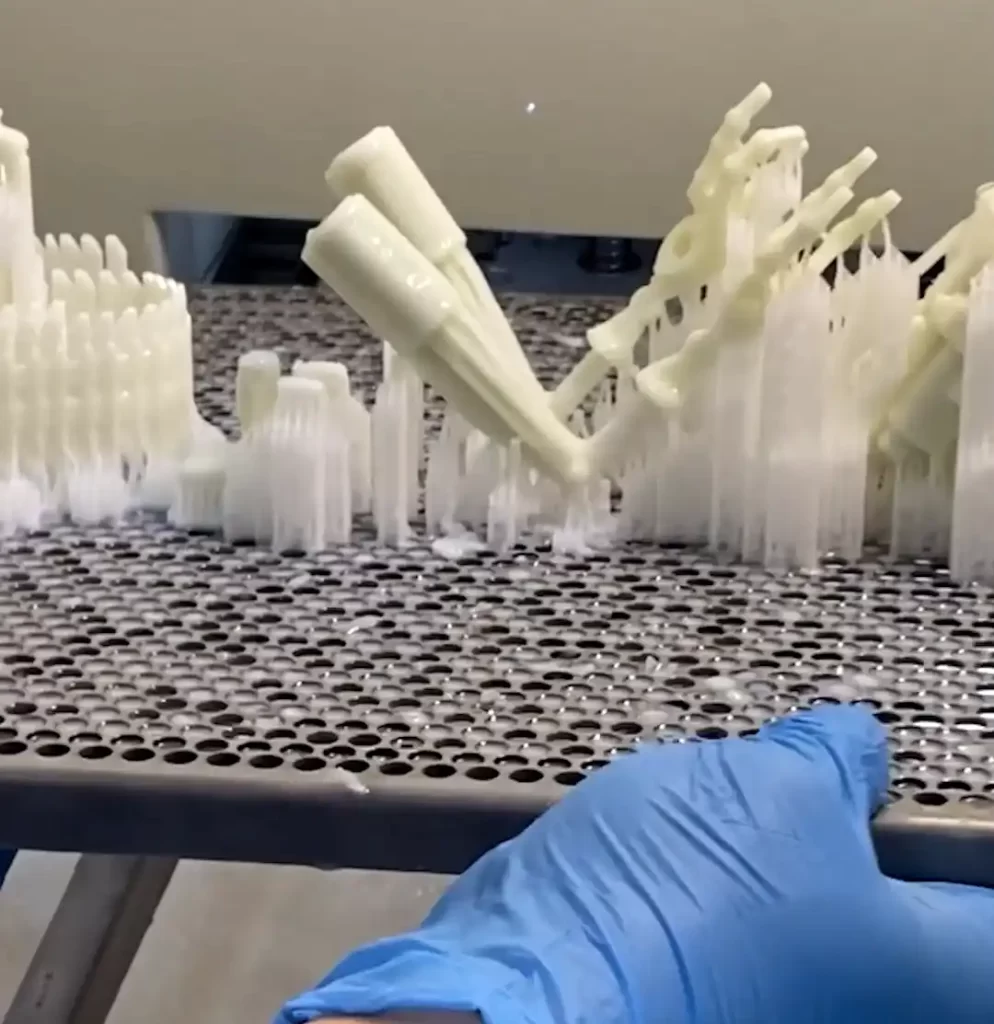

SLA 3D printing has revolutionized various industries with its versatility and precision. It is widely used in the prototyping process, allowing engineers and designers to quickly iterate and test their designs before moving to mass production. Additionally, SLA 3D printing is utilized in the medical industry for creating custom implants, prosthetics, and surgical guides. In the automotive industry, SLA 3D printing is used for rapid prototyping of car parts and components. The jewelry industry also benefits from SLA 3D printing, as it enables the production of intricate and detailed jewelry designs. With its wide range of applications, SLA 3D printing is transforming the way industries approach product development and manufacturing.

Technology behind SLA 3D Printing

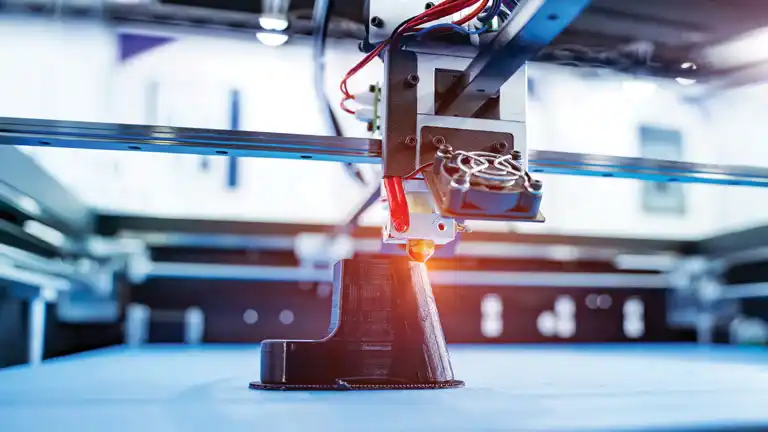

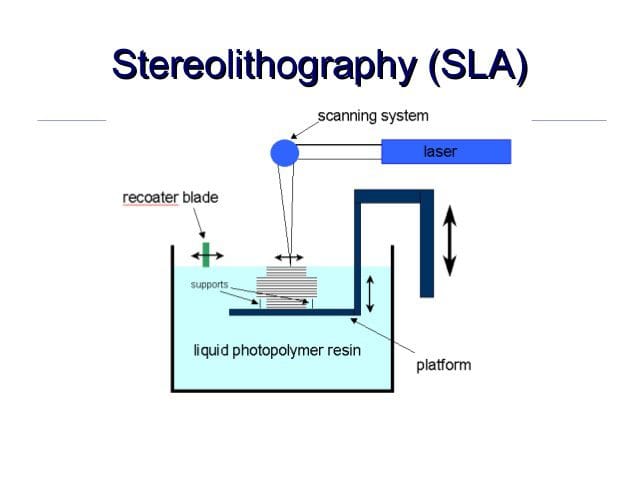

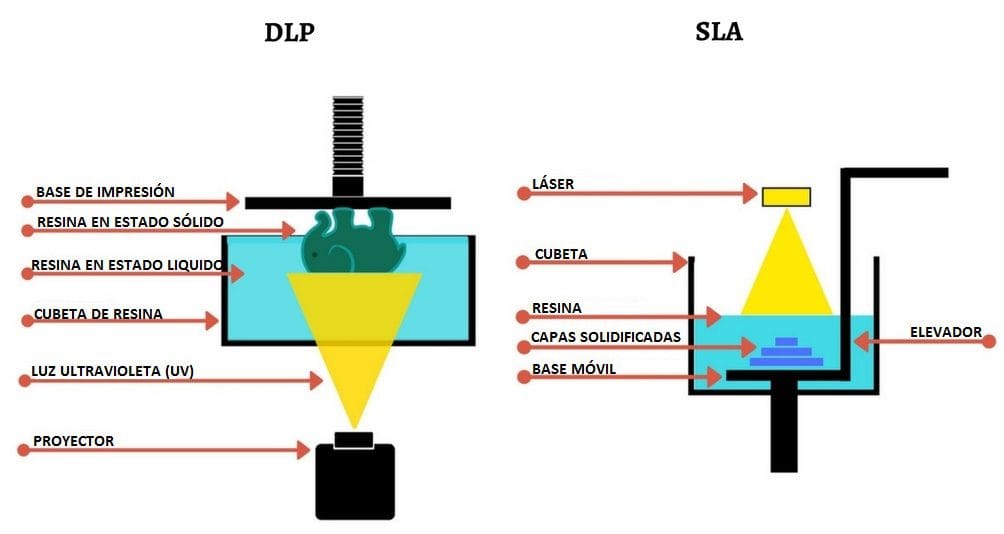

Working Principle of SLA 3D Printing

SLA 3D printing, also known as stereolithography, is a technology that uses a liquid resin that is cured by a UV light source to create solid objects layer by layer. The process starts with a digital model that is sliced into layers, and each layer is then projected onto a vat of liquid resin. The UV light selectively cures the resin, solidifying it and creating the desired shape. This technology allows for high precision and intricate details, making it ideal for creating complex geometries. The key components of an SLA 3D printer include a build platform, a resin vat, a UV light source, and a control system. Overall, the working principle of SLA 3D printing enables the creation of highly detailed and accurate prototypes and end-use parts.

Materials Used in SLA 3D Printing

SLA 3D printing utilizes a variety of photopolymer resins as the primary material for creating objects. These resins are specially formulated to solidify when exposed to ultraviolet (UV) light. They come in different colors and properties, allowing for the production of objects with varying characteristics. Some common types of photopolymer resins used in SLA 3D printing include standard resins, flexible resins, castable resins, and dental resins. Each type has its own unique set of properties, making them suitable for specific applications. For example, flexible resins are ideal for creating objects that require elasticity, while castable resins are used for producing molds and prototypes in the jewelry industry. The ability to use a wide range of materials is one of the key advantages of SLA 3D printing, as it enables the production of highly detailed and functional objects.

Comparison with Other 3D Printing Technologies

SLA 3D printing stands out among other 3D printing technologies due to its high precision and excellent surface finish. Unlike FDM printing, which relies on layer-by-layer deposition of material, SLA printing uses a liquid resin that is cured by a UV laser. This allows for the creation of intricate and detailed designs with smooth surfaces. Additionally, SLA printing offers a wider range of materials compared to other technologies, including high-performance resins and biocompatible materials. While other technologies have their own advantages, SLA 3D printing is a game-changer in terms of achieving complex geometries and producing high-quality prototypes.

Impact of SLA 3D Printing on Industries

Medical Industry

SLA 3D printing has had a significant impact on the medical industry, revolutionizing various applications. Customized prosthetics can now be created with high precision and accuracy, improving the quality of life for individuals in need. Additionally, biomedical models can be printed to aid in surgical planning and education. The ability to produce complex and intricate structures with SLA 3D printing has also facilitated the development of tissue engineering and drug delivery systems. With its ability to create patient-specific solutions, SLA 3D printing is transforming the way medical professionals approach treatment and care.

Automotive Industry

The automotive industry has greatly benefited from the advancements in SLA 3D printing technology. With its ability to produce highly detailed and complex parts, SLA 3D printing has revolutionized the prototyping and manufacturing processes in the automotive sector. It allows for faster and more cost-effective production of custom parts, reducing the time and resources required for traditional manufacturing methods. Additionally, SLA 3D printing enables the creation of lightweight and optimized designs, improving fuel efficiency and overall performance of vehicles. This technology has opened up new possibilities for rapid prototyping, concept modeling, and even the production of end-use parts in the automotive industry.

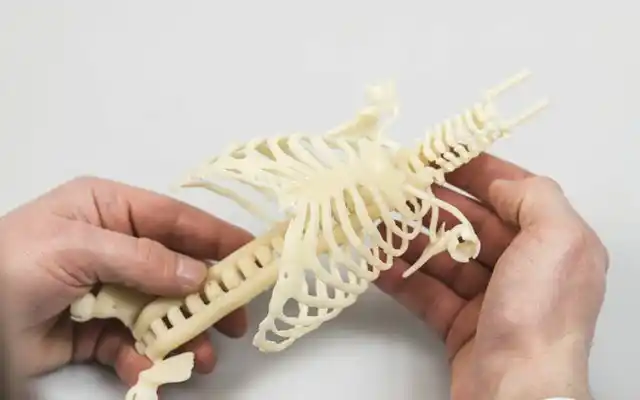

Jewelry Industry

The jewelry industry has been greatly impacted by the rise of SLA 3D printing. This technology has revolutionized the way jewelry is designed and manufactured. With SLA 3D printing, intricate and detailed jewelry pieces can be created with precision and accuracy. This has opened up new possibilities for jewelry designers to create unique and customized pieces. Additionally, SLA 3D printing allows for the use of a wide range of materials, including precious metals and gemstones, further enhancing the quality and value of the final products. As a result, the jewelry industry has seen increased efficiency, reduced costs, and improved customer satisfaction. SLA 3D printing is truly transforming the jewelry industry and pushing the boundaries of what is possible in jewelry design and production.

Conclusion

Future Potential of SLA 3D Printing

SLA 3D printing has the potential to revolutionize various industries and bring about significant advancements in technology. With its ability to produce highly detailed and intricate objects, SLA 3D printing is already making waves in fields such as medicine, automotive, and jewelry. In the medical industry, SLA 3D printing is enabling the creation of customized prosthetics, implants, and surgical models, leading to improved patient outcomes. In the automotive industry, SLA 3D printing is being used for rapid prototyping, reducing development time and costs. In the jewelry industry, SLA 3D printing is enabling the production of intricate and complex designs that were previously not possible. As the technology continues to advance and become more accessible, the future potential of SLA 3D printing is limitless.

Challenges and Limitations

Despite its many advantages, SLA 3D printing also faces several challenges and limitations. One of the main challenges is the limited range of materials that can be used in the printing process. SLA printers typically require specialized resins that are specifically designed for the technology, which can limit the range of applications. Another challenge is the cost of SLA printers and materials, which can be relatively high compared to other 3D printing technologies. Additionally, SLA printing can be a slow process, especially when printing complex and detailed objects. However, despite these challenges, SLA 3D printing continues to revolutionize various industries with its ability to create highly detailed and accurate prototypes and products.

Final Thoughts

In conclusion, SLA 3D printing has emerged as a revolutionary technology with a wide range of applications across various industries. Its ability to create highly detailed and intricate designs with exceptional accuracy has made it a preferred choice for industries such as medical, automotive, and jewelry. However, like any other technology, SLA 3D printing also faces challenges and limitations, such as the high cost of materials and the need for post-processing. Despite these challenges, the future potential of SLA 3D printing looks promising, as advancements continue to be made in the field. As industries continue to adopt this technology, it is expected to further revolutionize manufacturing processes and open up new possibilities for innovation and design.