Understanding SLA Resins: The Foundation of Precision 3D Printing

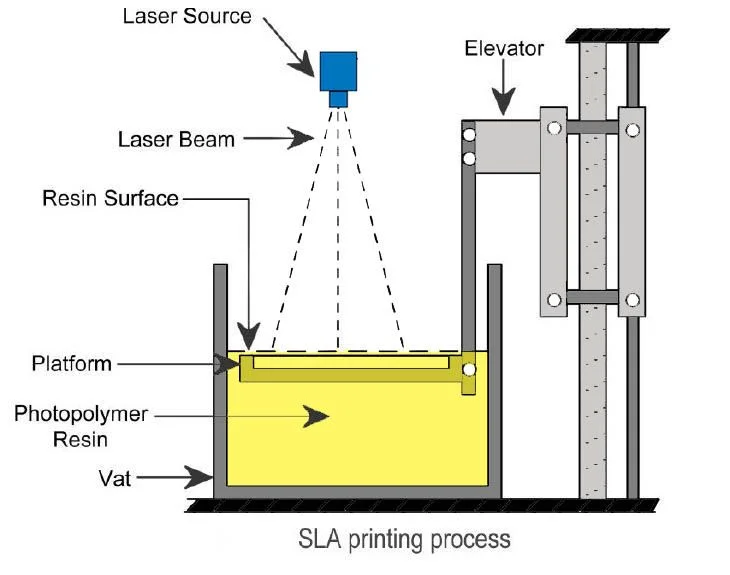

SLA (Stereolithography) resins enable high-resolution, smooth-surface 3D printing by curing under UV light. Their unique composition—monomers, oligomers, photoinitiators, and additives—facilitates rapid photopolymerization, forming solid polymer networks layer by layer.

Advantages Over Other 3D Printing Materials

| Material Type | State | Printing Process | Surface Finish | Typical Use Cases |

|---|---|---|---|---|

| SLA Resin | Liquid photopolymer | UV light cures resin layer | Smooth, high detail | Prototyping, jewelry, dental, engineering |

| FDM Filament | Solid filament | Heated nozzle melts filament | Layered, rougher | Functional parts, prototyping, hobbyist prints |

| DLP Resin | Liquid photopolymer | UV projector cures resin | Similar to SLA | Similar applications, often faster |

| SLS Powder | Powder | Laser sintering powder | Grainy, robust | Strong functional parts, complex geometries |

SLA resins excel in detail resolution and surface smoothness, making them ideal for precision-driven industries.

Types of SLA Resins: Tailoring Properties to Application Needs

Resin formulations vary significantly to meet mechanical, thermal, and optical requirements across sectors.

Common Resin Categories

- Standard Resins

- Balanced properties

- Suitable for general prototyping, concept models

- Tough/Durable Resins

- High impact resistance

- Ideal for snap-fit components, mechanical assemblies

- Flexible Resins

- Rubber-like elasticity

- Used in seals, gaskets, wearable devices

- Castable Resins

- Burn cleanly without residue

- Essential for investment casting in jewelry or dentistry

- Medical-Grade Resins

- Biocompatible with ISO 10993 certifications

- Applied in surgical guides, aligners, prosthetics

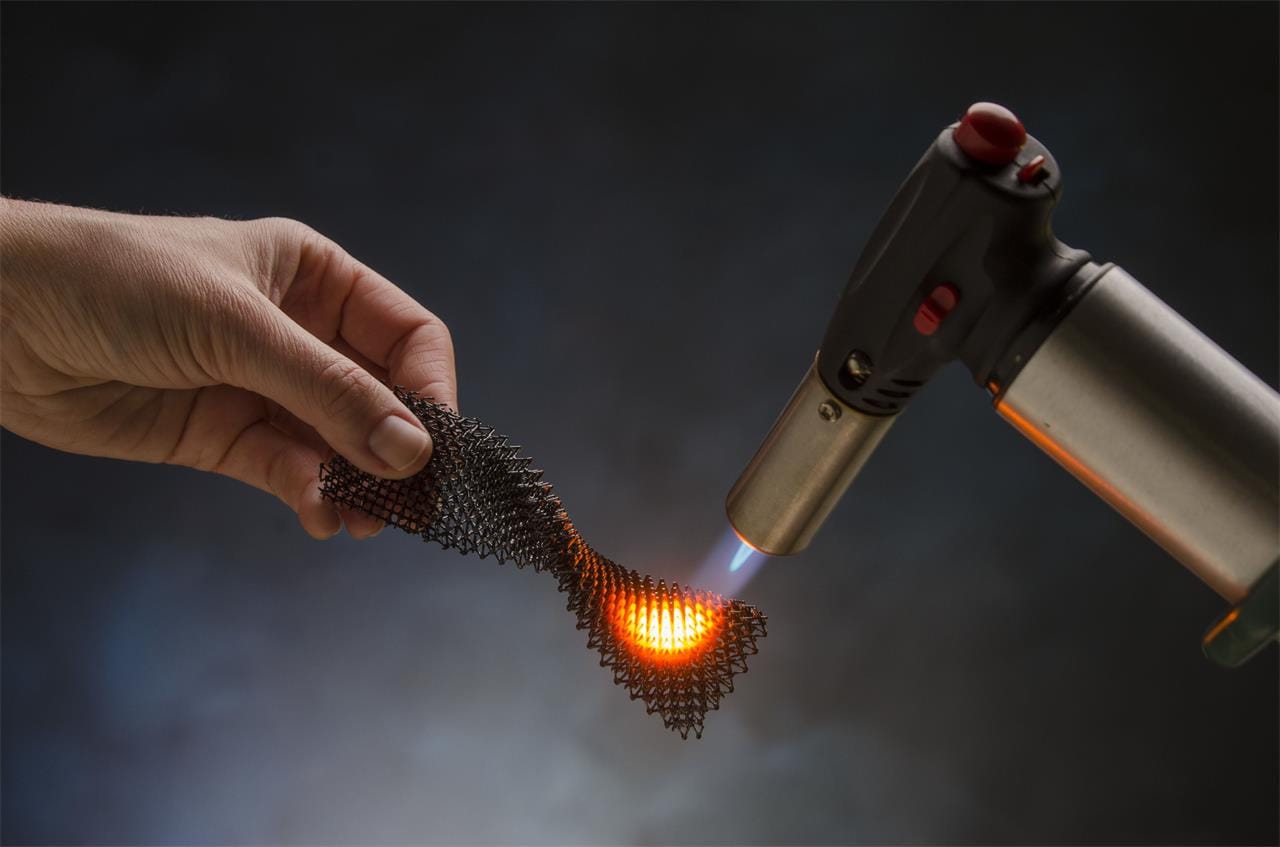

- High-Temperature Resins

- Heat deflection above 200°C

- Employed in molds, tooling, automotive parts

- Transparent/Specialty Resins

- Clear or colored variants

- Utilized in lenses, light pipes, artistic prototypes

| Resin Type | Key Properties | Typical Applications |

|---|---|---|

| Standard | Moderate strength, easy to print | Visual prototypes |

| Tough/Durable | High impact resistance | Functional mechanical parts |

| Flexible | Elastic, bendable | Seals, wearable devices |

| Castable | Clean burnout | Jewelry casting |

| Medical/Dental | Biocompatible, sterilizable | Surgical guides, dental appliances |

| High-Temperature | Heat-resistant | Tooling, molding |

| Transparent | Optical clarity | Lenses, art, display models |

Resin Composition and Chemistry

SLA resins consist of:

- Monomers/Oligomers: Form cross-linked networks during curing.

- Photoinitiators: Trigger polymerization upon UV exposure.

- Additives: Enhance flexibility, color, stability, or UV resistance.

During UV exposure, free radicals initiate chain reactions that bond monomers and oligomers into rigid structures. This process determines the final material’s mechanical behavior, curing speed, optical clarity, and environmental resistance.

Key Properties of SLA Resins

Mechanical Characteristics

| Property | Standard Resin Range | Enhanced Resins | Application Insight |

|---|---|---|---|

| Tensile Strength | 40–60 MPa | >70 MPa (tough) | Functional prototypes |

| Flexural Strength | 70–100 MPa | Higher (engineering-grade) | Structural components |

| Impact Resistance | Moderate | High (flexible/tough) | Shock-absorbing parts |

| Hardness (Shore D) | 65–75 | Variable | Wear resistance |

Optical Properties

- Transparency: Available in opaque, translucent, and fully clear options for optical components.

- Color Stability: Pigments may affect curing but allow branding.

- UV Resistance: Special formulations retain clarity over prolonged exposure.

Thermal Behavior

| Property | Standard Resin | High-Temp Resin | Use Cases |

|---|---|---|---|

| Heat Deflection Temp | 50–60°C | >200°C | Sterilization, tooling, heat exposure |

| Thermal Stability | Moderate | High | Automotive, aerospace applications |

Chemical Resistance

- Solvent Exposure: Standard resins degrade under acetone or alcohol; tough resins show improved resistance.

- Environmental Durability: Certain formulations withstand mild acids, fuels, and moisture better.

Biocompatibility and Safety

- Certifications Required: ISO 10993, USP Class VI.

- Applications: Medical implants, dental fixtures, skin-contact devices.

Post-Processing Considerations

- Curing Time: Varies from minutes to hours depending on formulation.

- Cleaning Requirements: Typically involves isopropyl alcohol washes.

- Surface Effects: Over-curing can cause yellowing or brittleness.

| Property | Importance | Resin Types with Enhanced Traits |

|---|---|---|

| Transparency | Optical clarity | Transparent, specialty blends |

| Heat Deflection Temperature | Thermal endurance | High-temp resins |

| Chemical Resistance | Exposure durability | Engineering, tough types |

| Biocompatibility | Medical/dental safety compliance | Medical/dental-grade |

| Post-Curing Needs | Final strength and surface finish | All SLA resins |

Applications of SLA Resins

Prototyping and Rapid Development

- Consumer Electronics: Enclosures and housing prototypes.

- Automotive Fit Tests: Dimensionally accurate mockups.

- Architectural Models: Fine-detail representations.

| Application Area | Key Resin Types Used | Benefits | Example Use Cases |

|---|---|---|---|

| Prototyping | Standard, Tough | Fast iteration, high fidelity | Electronics cases, models |

| Functional Parts | Tough, Flexible | Durability, heat resistance | Snap fits, tooling aids |

| Casting Applications | Castable | Clean burnout, fine detail | Jewelry molds, metal patterns |

| Dental & Medical | Biocompatible | Regulatory compliance | Surgical guides, aligners |

| Engineering Support | High-temp, Tough | Heat and wear resistance | Jigs, fixtures, mold inserts |

| Artistic Creations | Transparent, Colored | Aesthetic appeal | Miniatures, sculptures |

End-Use Components

- Industrial Tooling: Mold inserts, jigs, and fixtures.

- Custom Manufacturing Aids: Ergonomic grips, assembly-line tools.

- Low-Volume Production: Complex geometries without injection molding costs.

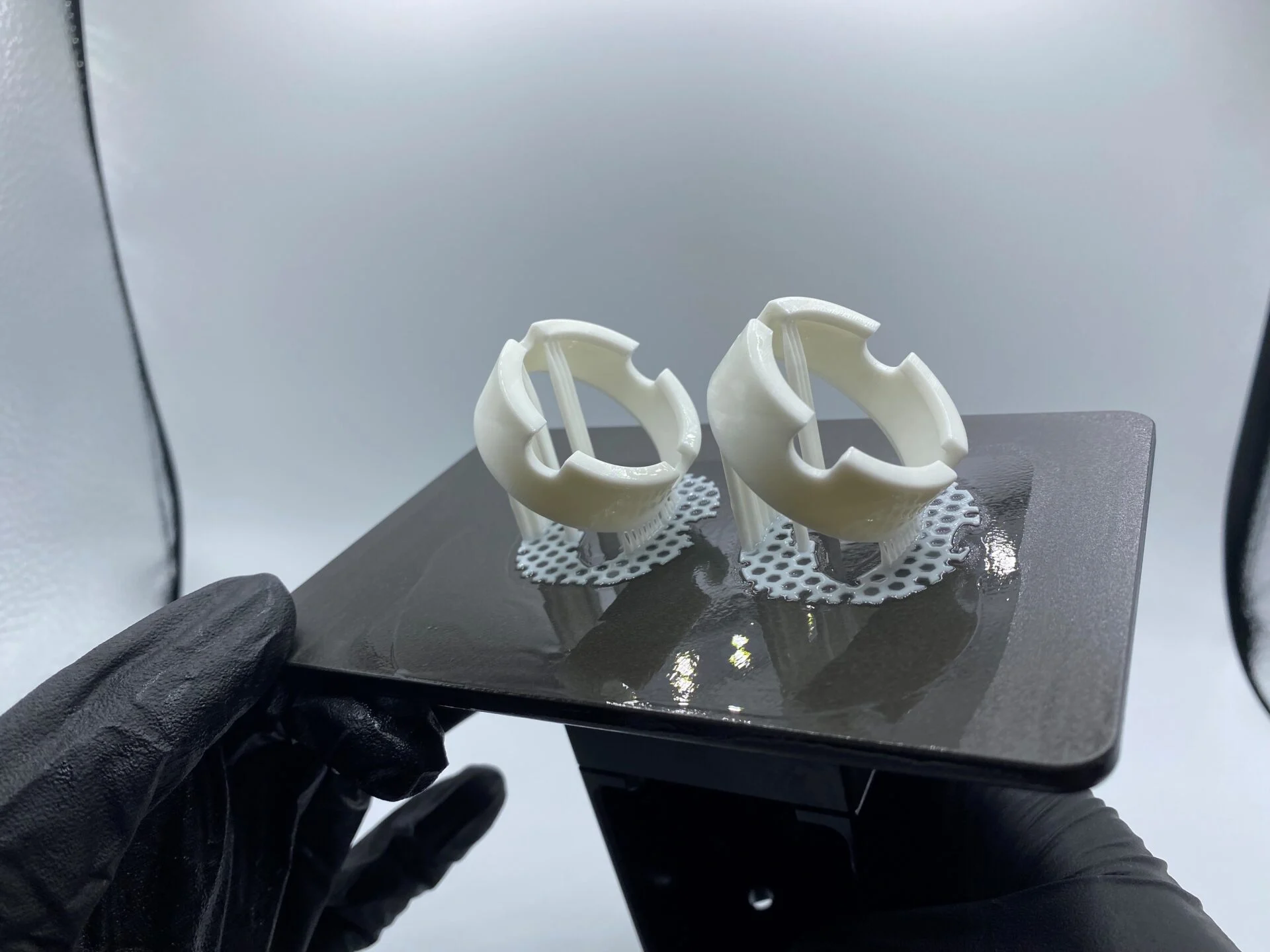

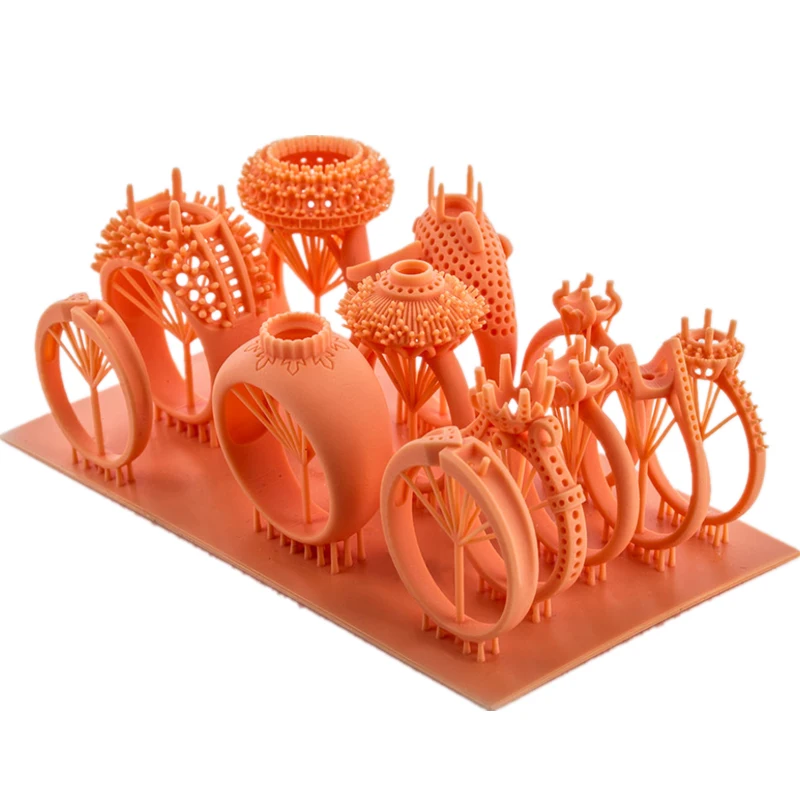

Jewelry and Investment Casting

- Castable Resins: Eliminate wax carving, enabling intricate designs.

- Burnout Cleanliness: Leave no ash, ensuring pristine metal finishes.

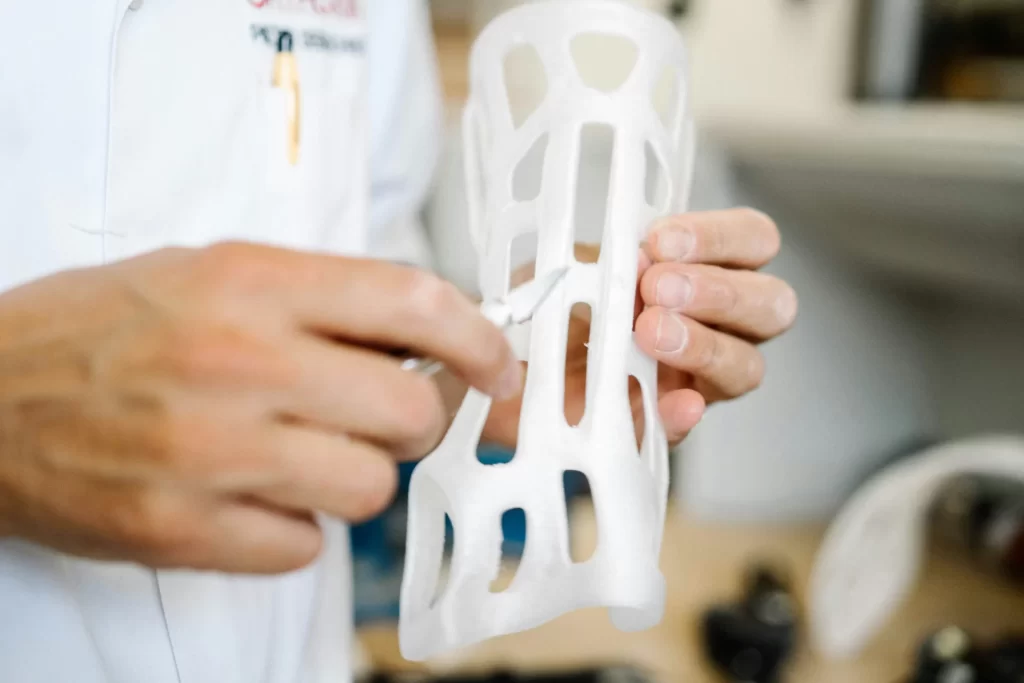

Healthcare and Dentistry

- Precision Surgical Guides: Custom-fitted based on patient anatomy.

- Orthodontic Appliances: Aligners, crowns, and prosthetics.

- Hearing Aid Shells: Ergonomic, lightweight designs.

Engineering and Industrial Uses

- Tooling and Fixtures: Lightweight yet durable production aids.

- Mold Inserts: Heat-resistant materials enable short-run molding.

Creative Projects

- Miniature Figurines: Detailed tabletop game pieces.

- Cosplay Accessories: Lightweight, custom-fitted props.

- Art Installations: Transparent and colored resins enable visual effects.

How to Choose the Right SLA Resin

| Project Type | Recommended Resin Type | Rationale |

|---|---|---|

| Visual Prototyping | Standard | Affordability, smooth surfaces |

| Functional Stress | Tough/Durable | Load-bearing capabilities |

| Bending/Flexibility | Flexible | Shock absorption, elastic return |

| Jewelry Casting | Castable | Clean burnout, dimensional accuracy |

| Medical/Dental Use | Biocompatible | Regulatory compliance |

| High-Temp Environments | High-Temperature | Thermal endurance |

| Decorative/Visual | Transparent/Specialty | Optical clarity, aesthetic customization |

Selection Criteria

- Mechanical Demand: Evaluate tensile and flexural strength, elongation at break.

- Environmental Exposure: Heat, chemicals, UV light.

- Aesthetic Goals: Color, transparency, surface texture.

- Biocompatibility: Certifications required for medical use.

- Post-Processing Compatibility: Curing time, cleaning ease.

Supplier Considerations

- Verify resin compatibility with your printer model.

- Check manufacturer credentials and technical support availability.

- Ensure compliance with international standards (ISO, RoHS).

Handling and Safety Guidelines

Storage Best Practices

- Store in original containers away from UV sources.

- Maintain temperature between 15°C and 30°C.

- Monitor expiration dates; shelf life typically 6–12 months unopened.

Personal Protective Equipment (PPE)

| Task | Recommended PPE |

|---|---|

| Resin pouring/mixing | Nitrile gloves, goggles, lab coat |

| Print cleaning | Gloves, eye protection |

| Post-curing | UV-protective eyewear (optional) |

Environmental Responsibility

- Do not dispose of uncured resin down drains.

- Harden leftover resin before disposal.

- Recycle resin containers where possible.

Troubleshooting Common Issues

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Incomplete curing | Old resin, low UV power, wrong settings | Use fresh resin, check lamp, adjust timing |

| Poor layer adhesion | Build plate misalignment, resin mix | Level build plate, clean, stir resin |

| Warping | Shrinkage, peel speed, temp changes | Use low-shrink resin, slow peeling |

| Sticky post-cure surface | Under-curing, equipment issue | Increase curing time, maintain equipment |

| Resin thickening | Heat/UV exposure, expired resin | Store properly, filter, replace if needed |

| Resin discoloration | Oxidation, UV exposure | Store in dark, sealed containers |

Future Trends in SLA Resins

Sustainable Innovations

- Bio-Based Resins: Derived from plant oils, reducing reliance on fossil fuels.

- Biodegradable Variants: Break down safely after use; early commercial adoption underway.

Advanced Performance

- Nano-Enhanced Composites: Improve mechanical strength and thermal resistance.

- High-Temp Engineering Resins: HDT beyond 250°C for industrial environments.

Functional Integration

- Conductive Resins: Enable printed electronics and sensors.

- Magnetic Resins: Facilitate smart actuators and robotics.

Industry-Specific Customization

- Medical Implants with Drug Delivery: Embedded therapeutic compounds.

- Hybrid Resins: Combine rigid and flexible segments within a single print.

AI-Driven Development

- Predictive Modeling: Optimizes resin chemistry for performance and consistency.

- Digital Simulation Tools: Accelerate new material development cycles.

Regulatory and Environmental Shifts

- Low-VOC Formulations: Reduce workplace exposure.

- Circular Economy Initiatives: Recycling programs for resin waste.

| Trend | Description | Expected Impact |

|---|---|---|

| Bio-based and Biodegradable | Renewable feedstock, eco-friendly breakdown | Reduced environmental footprint |

| Enhanced Mechanical/Thermal | Stronger, heat-resistant resins | Expanded industrial applications |

| Functional Materials | Conductive, magnetic, drug-delivery resins | Multi-functional device integration |

| Industry-Specific Customization | Tailored resin formulations | Improved performance and regulatory alignment |

| AI and Digital Development | Data-driven resin optimization | Faster innovation, batch-to-batch consistency |

| Green Regulations | Low-VOC, recycling initiatives | Safer production, sustainable manufacturing |

Conclusion

SLA resins offer unparalleled precision and versatility across multiple industries. By understanding their chemical and mechanical properties, users can optimize material selection, enhance print reliability, and expand application possibilities. As research advances, next-generation resins will further improve sustainability, functionality, and performance—making SLA an increasingly essential technology for modern manufacturing, healthcare, and creative industries.