Have you ever wondered how the marvels of 3D printing come to life? From intricate miniature models to large-scale architectural mockups, the magic of 3D printing is all around us. And at the heart of it are two critical materials that facilitate this phenomenon – PLA and SLA.

Choosing the correct 3D printing material is no less important than choosing the right words for a speech – it can make or break the final outcome. PLA (Polylactic Acid) and SLA (Stereolithography) are two commonly used materials in the 3D-printing world, each offering unique characteristics. They are both favored for different reasons and applications, but what are their key differences?

If you’ve always wondered how to differentiate between PLA and SLA, or if you’re contemplating which one would best suit your next 3D printing project, you’ve come to the right place. In this blog post, we’ll dive deep into their origin, characteristics, differences, and uses. We’ll also compare their strengths and weaknesses and walk you through practical guidelines and expert tips on choosing one over the other for various applications.

Detailed Introduction of PLA

What is PLA?

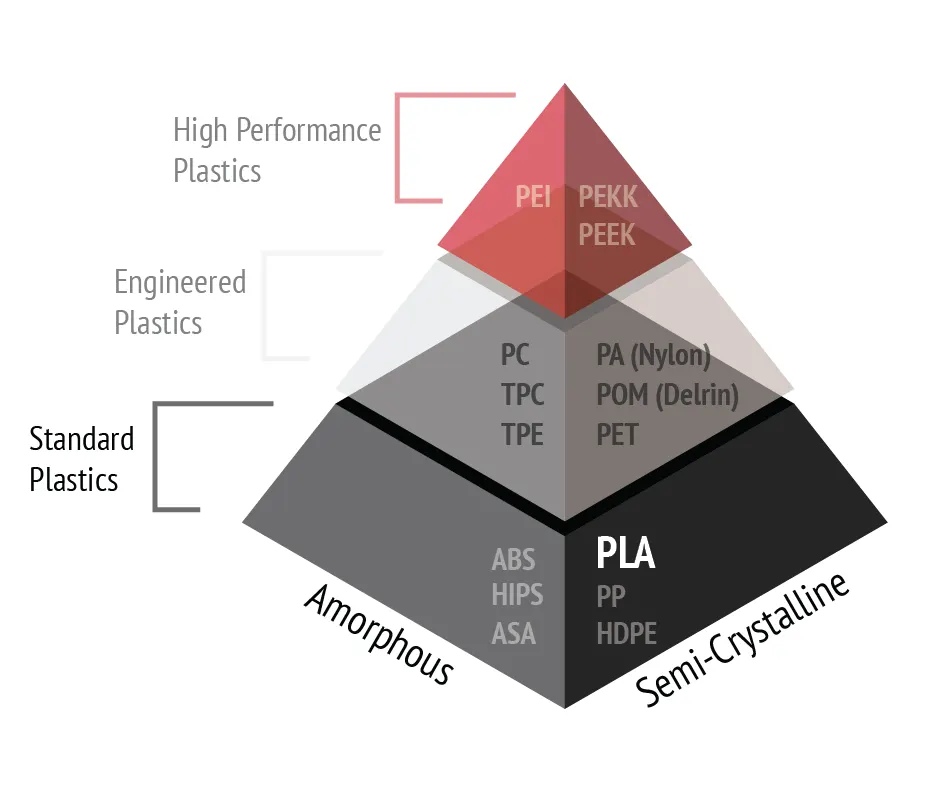

Polylactic Acid, or **PLA**, is a biodegradable thermoplastic derived from renewable resources like corn starch or sugar cane. Over recent years, PLA has become a popular choice in the 3D printing community due to its low toxicity and ease of use.

History/development

PLA was first discovered in the 1930s but it didn’t gain popularity until the late 1980s, when researchers started searching for more environmentally friendly plastics. Most traditional plastics are derived from non-renewable petroleum resources, making PLA an attractive alternative.

The Process of PLA 3D Printing

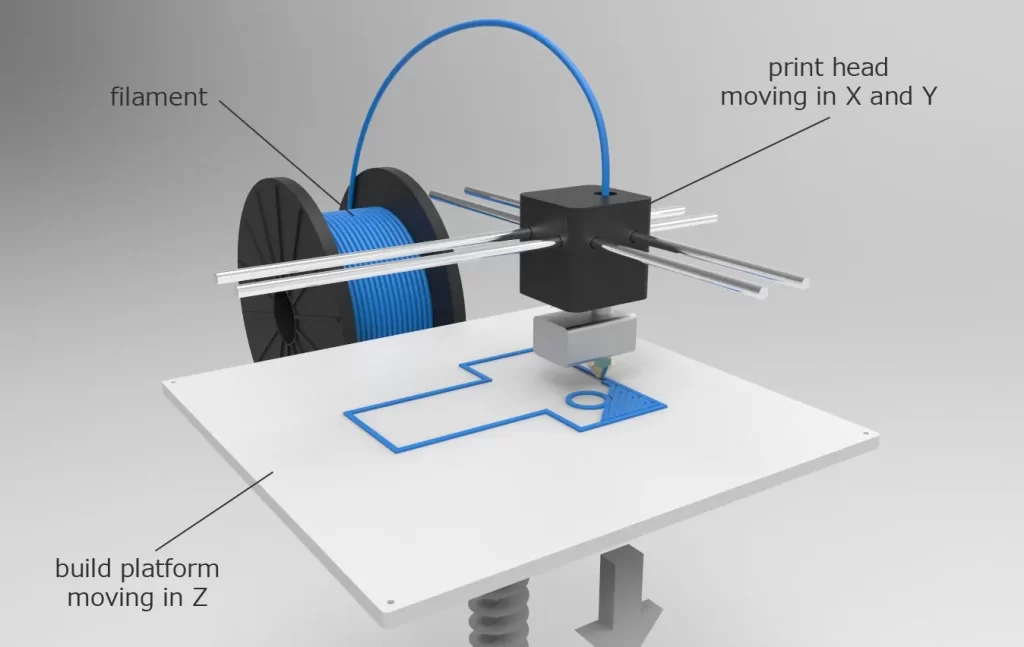

PLA is usually used in a type of 3D printing called Fused Deposition Modeling (FDM).

Here’s a simplified breakdown of the process in steps:

- The PLA filament is pre-heated in the 3D printer’s nozzle.

- The heated PLA is then deposited layer by layer on the print bed.

- As the PLA cools, it solidifies, creating the final 3D object.

Key Characteristics of PLA

To truly understand the allure of PLA, let’s delve into its principal properties:

Mechanical Properties

- Strength: PLA’s tensile strength is high, but its durability under stress can be less than other materials like ABS.

- Flexibility: It has lower flexibility compared to some other 3D printing materials.

- Shrinkage: Minimal shrinking makes it an excellent choice for larger prints and designs with fine details.

Thermal Properties

- Melting Point: PLA tends to have a lower melting temperature, typically around 180-220°C, which is a feature that makes it easier to print with.

- Cooling: PLA cools rapidly, reducing the chances of warping during printing.

Visual/Cosmetic Properties

- Surface Finish: PLA offers a slightly glossy surface finish, giving printed objects a pleasing aesthetic.

- Color Variety: It’s available in a wide range of vibrant colors, as well as translucent and glow-in-the-dark variants.

Applications and Use Cases of PLA

Due to its versatile nature, PLA finds uses in a wide range of applications. Here are a few common uses:

- Prototypes: Given its low cost and ease of use, PLA is often the go-to material for prototyping.

- Educational Use: Its non-toxic nature makes it an appealing choice for school projects and educational activities.

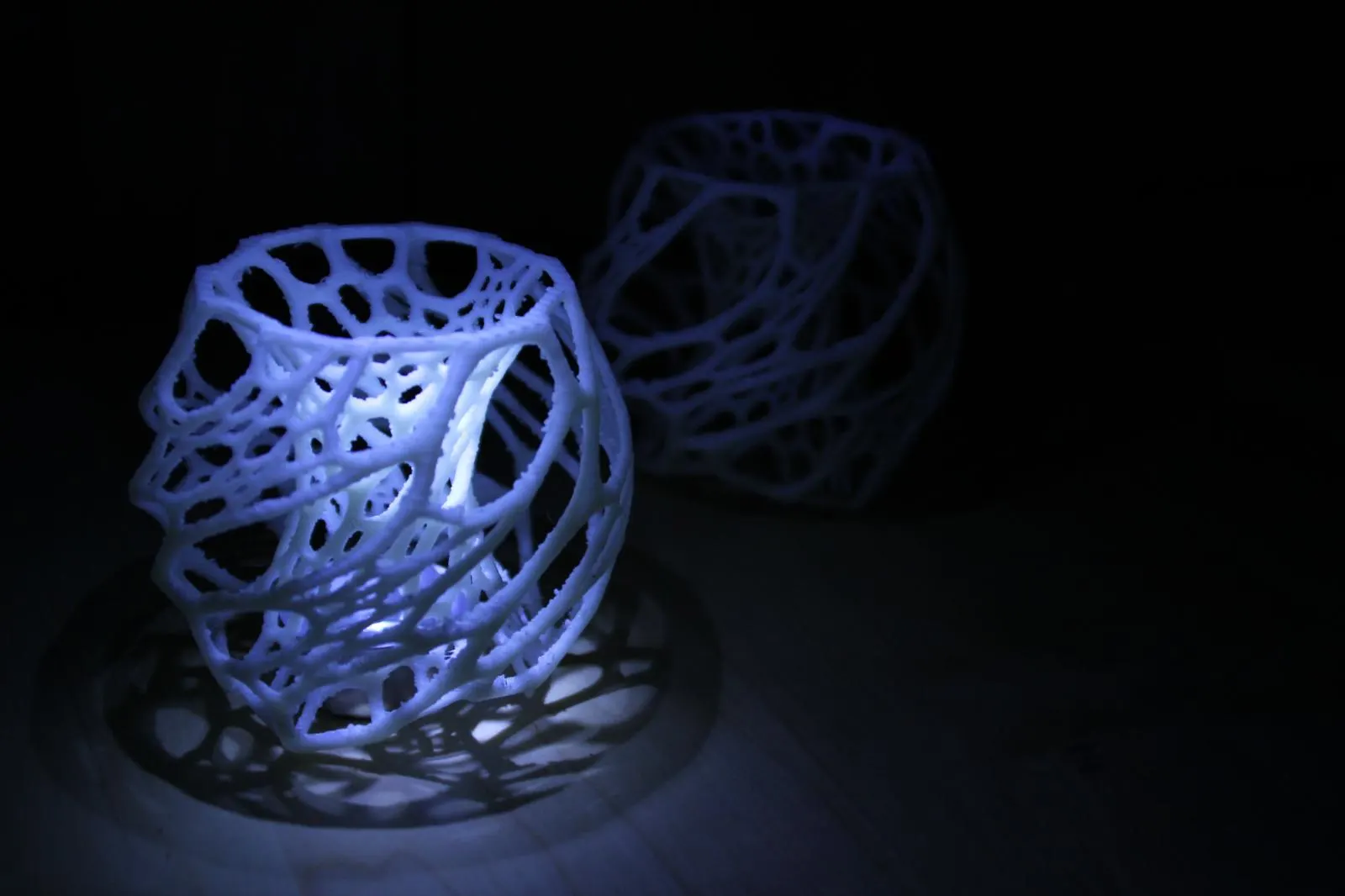

- Home Decors: From vases to candle holders, the possibilities are endless with PLA’s aesthetic appeal.

But like anything, PLA has its set of drawbacks to take into account. It’s not as heat resistant as other materials, which can limit its functional applications. Additionally, while it is biodegradable, the degradation process is quite slow and requires industrial composting conditions.

Regardless of its pros and cons, PLA’s popularity continues to soar amongst 3D printing enthusiasts, from hobbyists to professionals.

Detailed Introduction of SLA

What is SLA?

Stereolithography (SLA) may sound like a term straight out of science fiction, but it’s rooted deeply in the tangible world of 3D printing. SLA is the first-ever 3D printing technology invented, and it remains a popular choice among professionals for its high precision and smooth surface finish.

History/Development

This cutting-edge technology was developed in the 1980s by Chuck Hull. He patented SLA and later co-founded 3D Systems Corporation, one of the leading companies in 3D printing today.

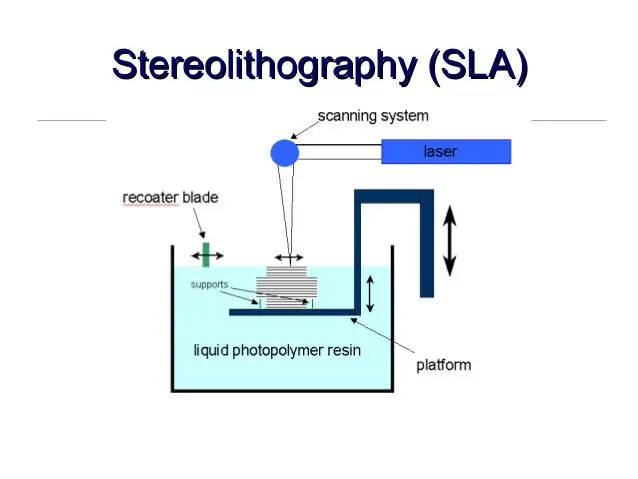

The Process of SLA 3D Printing

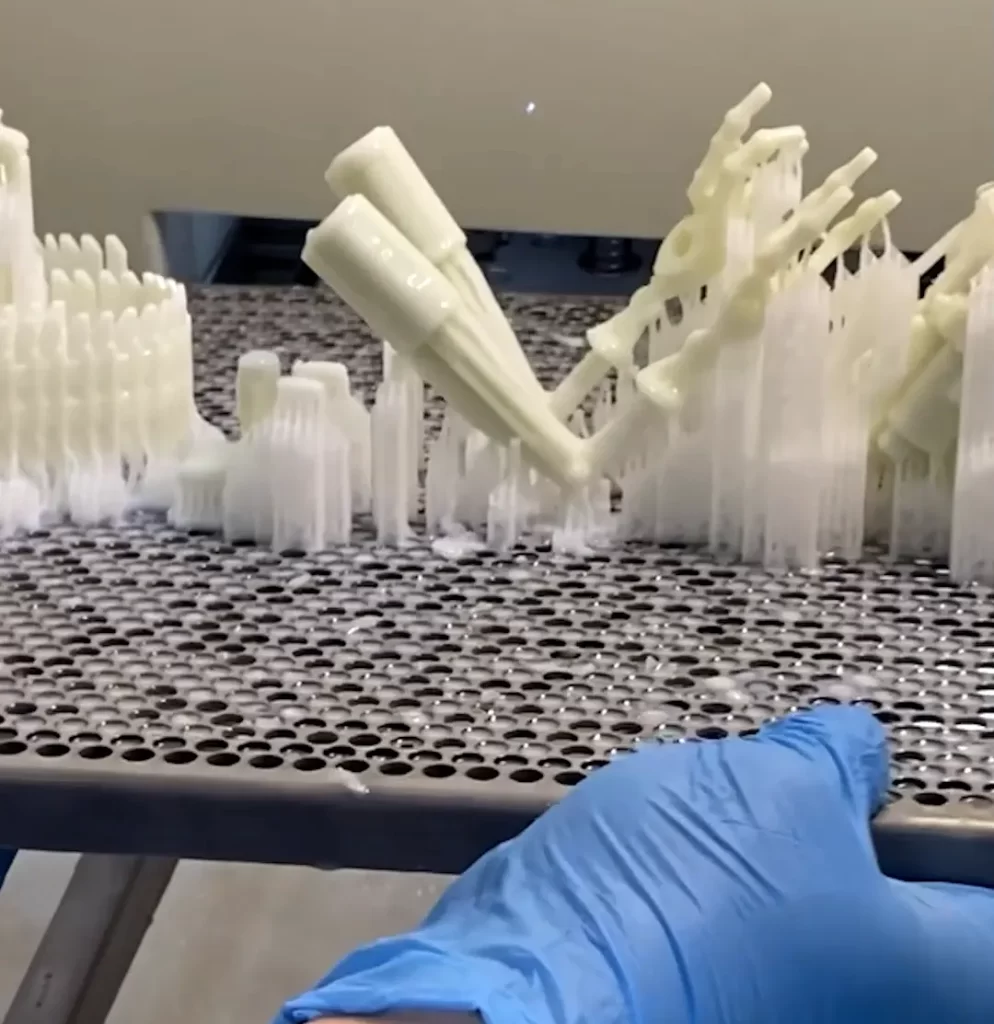

In an SLA 3D printer:

- A laser beam is focused on a tank full of photopolymer resin.

- The light from the laser cures and solidifies the layer of resin in the shape of the design.

- The build platform then moves up, allowing a new layer of resin to flow under the item.

- This process is repeated layer by layer until the object is complete.

Key Characteristics of SLA

Let’s dive into the key attributes that set SLA apart:

Mechanical Properties

- Strength: Because SLA uses a solid block of resin, printed parts tend to be strong and fully dense.

- Flexibility: SLA printed parts are typically rigid and can be brittle depending on the resin.

- Accuracy: SLA stands out for its high dimensional accuracy and detail, allowing for intricate designs and small features.

Thermal Properties

- Curing: SLA parts need to be post-cured in UV light to reach their final hardness and thermal properties.

- Heat Resistance: The heat resistance of SLA prints can be quite high, depending on the choice of resin.

Visual/Cosmetic Properties

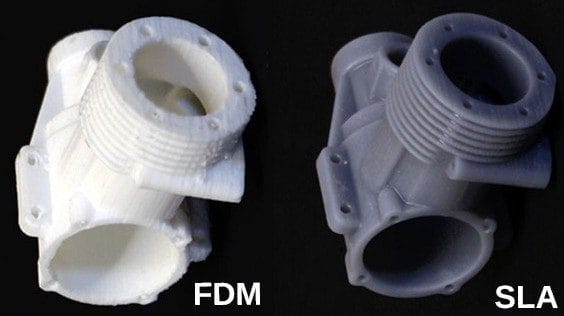

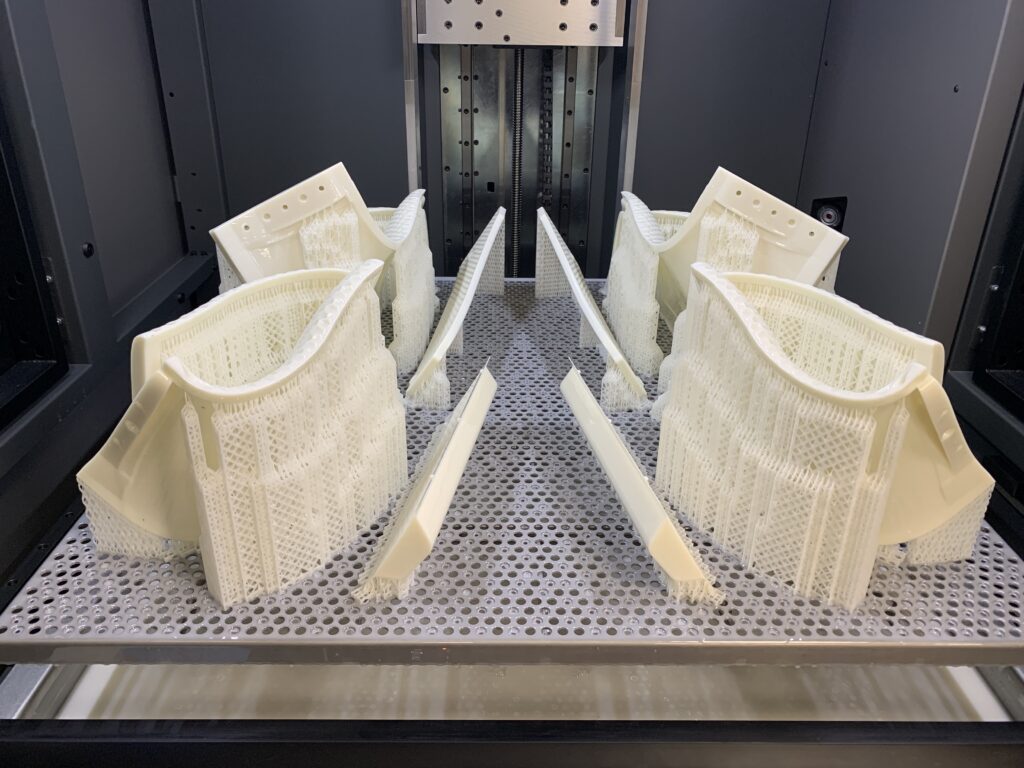

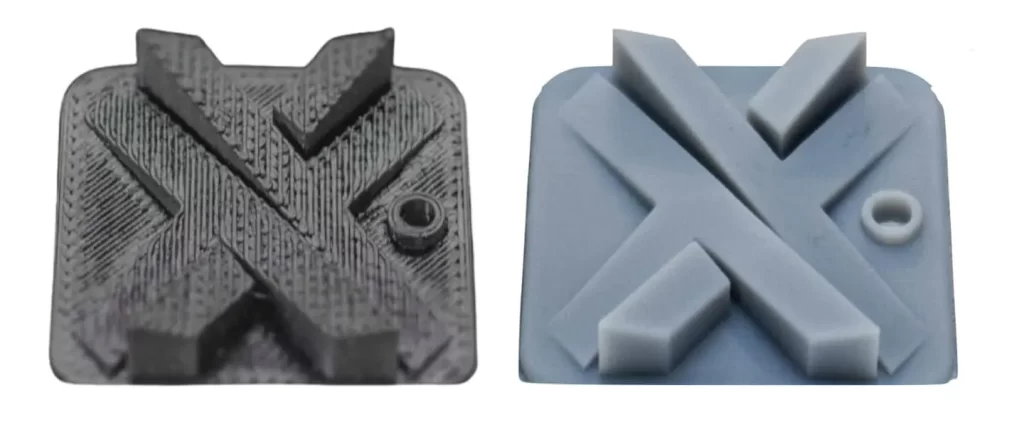

- Surface Finish: SLA features smooth surface finishes, one of the key reasons it is favored for producing prototypes.

- Detail: High precision means fine details reproduce exceptionally well with SLA.

Applications and Use Cases of SLA

SLA is favored in a range of high-precision applications. Here are a few examples:

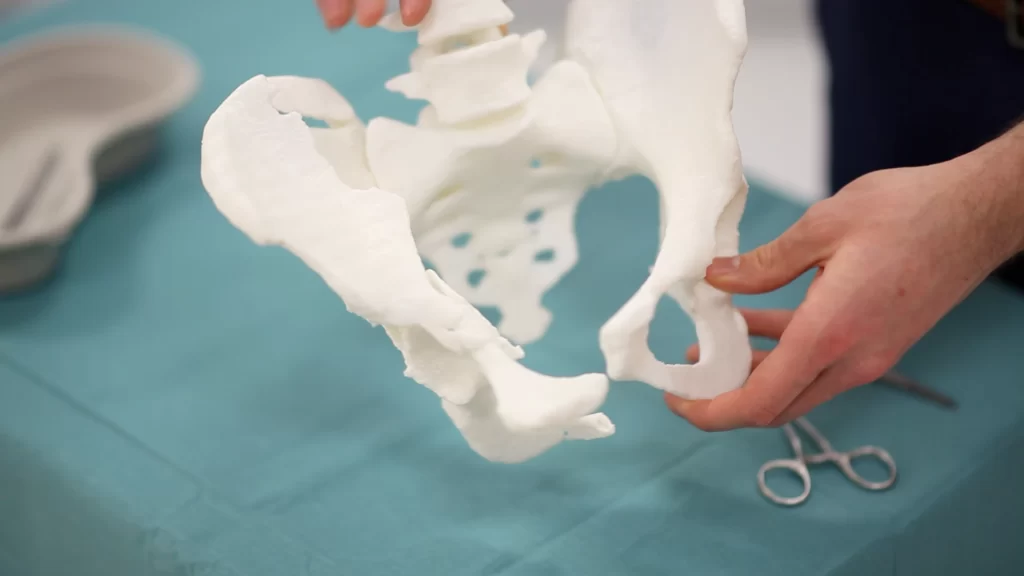

- Medical: SLA has been used to print medical models for surgical planning.

- Dentistry: Dental aligners, crowns, and other products can be made using SLA.

- Jewelry: The high detail of SLA is perfect for creating intricate jewelry designs.

However, it’s crucial to remember that SLA printers and resins come at a higher price point than FDM and PLA, making them less accessible for casual hobbyists. In addition, SLA prints can be brittle and may not appropriate for mechanically stressed parts.

PLA vs SLA: The Comparison

Now that we have individually delved into the details of both PLA and SLA, it’s time to put them head-to-head and unravel the significant differences and where each shines.

1. Raw Materials and 3D Printing Process

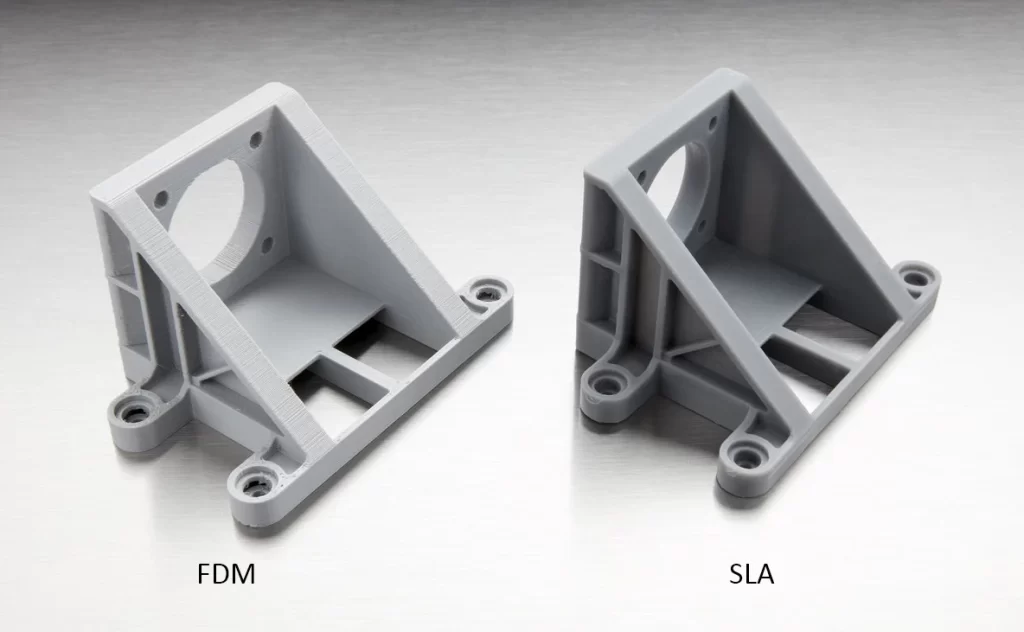

While PLA uses cornstarch or sugarcane as the base material, SLA employs liquid resin for creating 3D components. Comparatively, PLA is utilized in Fused Deposition Modeling (FDM), which involves heating and extruding plastic, piece by piece, layer by layer.

SLA technology, on the other hand, uses a completely different method. It employs a laser to cure the resin, creating a more seamless layering process, resulting in smoother and more detailed prints.

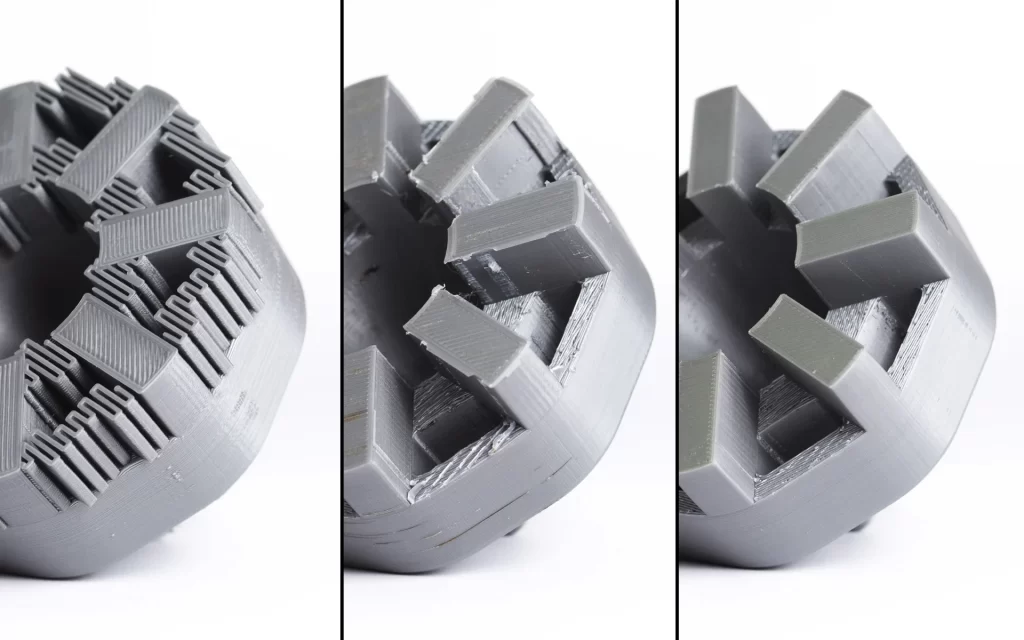

2. Resolution and Detail

Although both offer impressive resolutions, **SLA often edges out in terms of precision**. The nature of its process allows for intricate details and a smoother finish that PLA often can’t achieve. However, PLA with high-end FDM printers can come close and is noticeably improved over its general standard.

3. Strength and Durability

In terms of strength, **PLA tends to have the upper hand**. The nature of FDM printing, as well as the granular structure of PLA, leads to better stability and more significant resistance to impact.

SLA prints, while accurate and visually stunning, are often brittle and can fracture under pressure or impact. This makes PLA a more suitable candidate for large prototypes or parts that might be subjected to mechanical stress.

4. Cost

When it comes to cost, **PLA takes the win**. It’s a more affordable printing material and FDM printers are generally less expensive than SLA printers. Additionally, the upkeep cost for an FDM printer is typically lower.

SLA’s high precision and quality, including the use of costly resins and regular replacements of the resin tank, contribute to a higher total cost of ownership.

5. Safety and Environmental Impact

Both PLA and SLA have safe operating procedures. PLA is generally considered safer simply due to it being used in FDM, which has fewer potential hazards.

On the environmental side, PLA is biodegradable and made from renewable sources, giving it some advantage. However, it’s key to consider that it biodegrades slowly and typically in industrial composting conditions.

Practical Applications and Choosing the Right One for You

Having understood the differences between PLA and SLA, you might be wondering, “Which one is right for me?” The truth is, it depends on what you’re trying to achieve with your 3D printing project. Here’s a breakdown of what you might want to consider.

1. When to Use PLA?

PLA is a great choice for beginners and hobbyists considering its ease of use and affordability. Given below are a few instances when PLA proves to be an excellent choice:

- Prototyping: If you need to rapidly create prototypes, PLA is your go-to due to its ease of printing. Models printed using PLA give you a fair idea of what to expect from the final product.

- Educational Use: Due to its non-toxic nature, PLA is widely used in schools and community learning centers.

- Display Pieces and Non-Functional Items: If you’re looking to design aesthetic pieces like home decoration, costumes, low-stress toys, and tabletop games, PLA’s vibrant color palette and glossy finish can be advantageous.

2. When to Use SLA?

SLA is ideal for professionals looking for highly precise prints, and for those who need parts with a smooth finish. Here’s when you might want to consider SLA:

- High Detail Models: This can range from intricate jewelry and miniatures to highly-detailed and proportionate architectural models.

- Professional Prototypes: When you need a prototype that mirrors the final product in terms of detail and finish, SLA is a worthy investment. One important example is in dental and healthcare models.

- Molds: In certain industries, SLA is used to create molds due to its exceptional precision.

3. Things to Consider When Making a Choice

Several aspects need to be considered when deciding between PLA and SLA:

- Cost: Consider not only the upfront cost of the printers and materials but also the cost of maintenance and replacement parts.

- Use Case: What are you printing? An intricate piece of jewelry or a simple prototype?

- Safety: Do you have a well-ventilated space for SLA printing?

Though PLA and SLA fall under the wide umbrella of 3D printing technologies, each has carved out its own unique space catering to their specific strengths and use cases. Understanding their differences and similarities will enable you to choose the right material for your next 3D printing project.

Frequently Asked Questions (FAQs) about PLA and SLA

We’ve explored PLA and SLA in detail, but you might still have a few questions lingering. Let’s address some common queries about these two popular 3D printing technologies.

1. Can SLA Printers Use PLA?

While a common question, it’s based on a fundamental misunderstanding of the two technologies. PLA is a type of printing material, typically used in FDM printing. SLA printers, on the other hand, use liquid resin, which is a completely different medium.

2. Which is More Environmentally Friendly, PLA or SLA?

In terms of raw materials, PLA gets the edge as it is derived from renewable resources and is biodegradable in professional composting facilities. On the other hand, though liquid resins for SLA are evolving to become more eco-friendly, they are not inherently biodegradable and therefore less environmentally friendly.

3. I Need High Resolution. Should I Choose PLA or SLA?

You can achieve high-resolution prints with both PLA and SLA, but for the highest level of detail and smoothness, SLA is your best bet. The laser-aided tech is capable of remarkable levels of detail, as thin as 25 microns!

4. Can I sand or machine PLA and SLA prints?

Yes, both PLA and SLA can be post-processed. PLA prints are easy to sand or machine, while SLA prints are more brittle but offer smoother surfaces that may require less work.

5. Is PLA or SLA better for Large Prints?

Typically, PLA and FDM printers are better suited for large prints. FDM printers are commonly available in larger sizes than SLA printers, making them more suitable for hefty print tasks.

6. Which One is More Durable – PLA or SLA?

While both have their strengths, PLA is generally more durable than SLA, especially when it comes to mechanical stress or impact.