You’ve found the right place if you are looking for a low-cost SLA 3D printer.

SLA printers are similar to traditional 3D printers but use a different material.

SLA materials are generally available in white,transparency and yellow colors.

Because they are blended versions of their base materials, colors will vary.You can also mix pigments to create different colors, but this is more difficult.

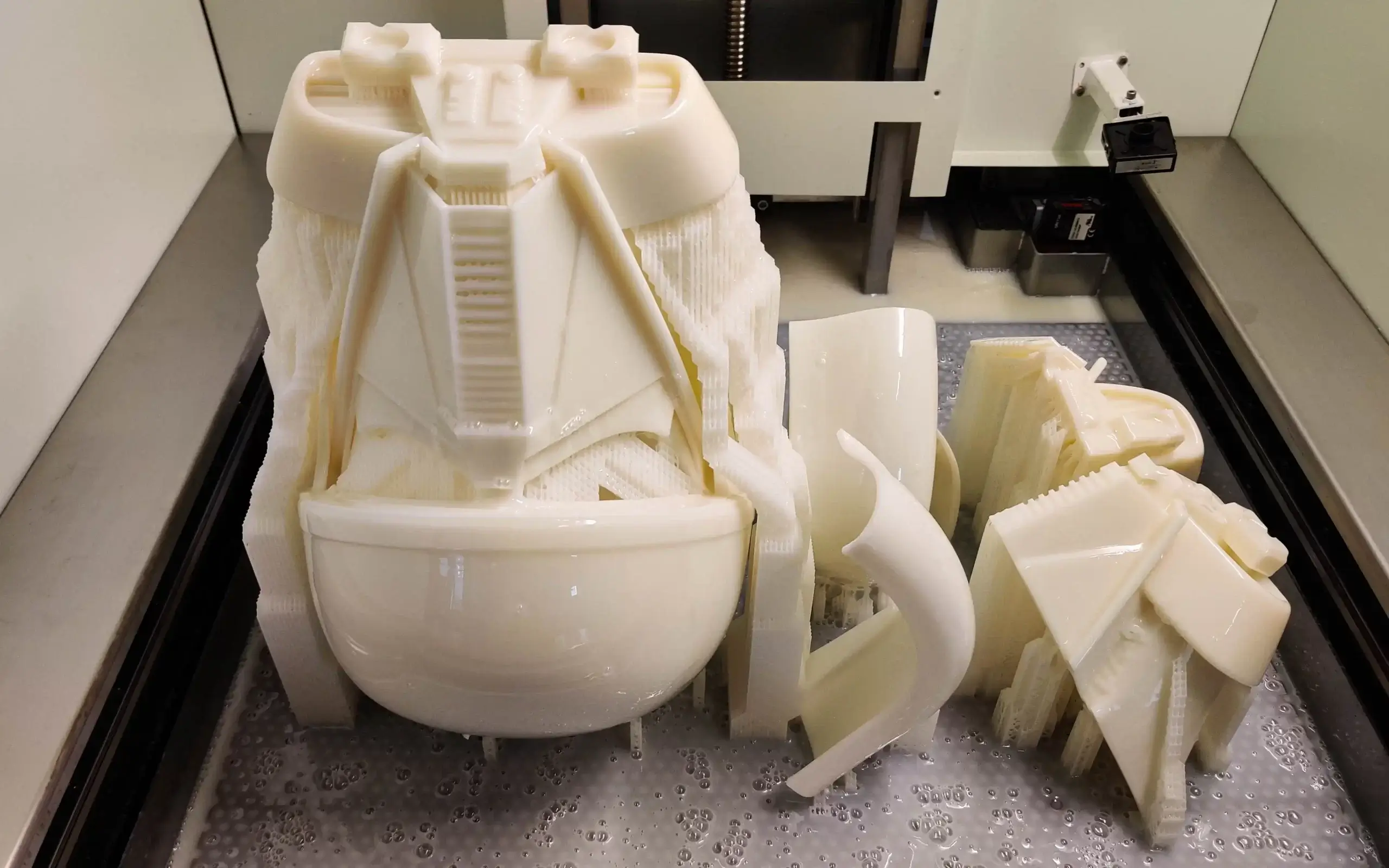

SLA printers can produce durable, high-quality objects with great accuracy, but they have their limitations.SLA printers are a great solution.You can use multiple printers on one machine depending on what type of model you are trying to make.

SLA 3D printing makes industrial manufacturing easier.It also made it possible to scale production incrementally by adding smaller format printers as needed.This method also allows you to print in multiple materials on each printer.This model has also been improved by the use of advanced materials.This technology opens up new manufacturing possibilities beyond prototyping.

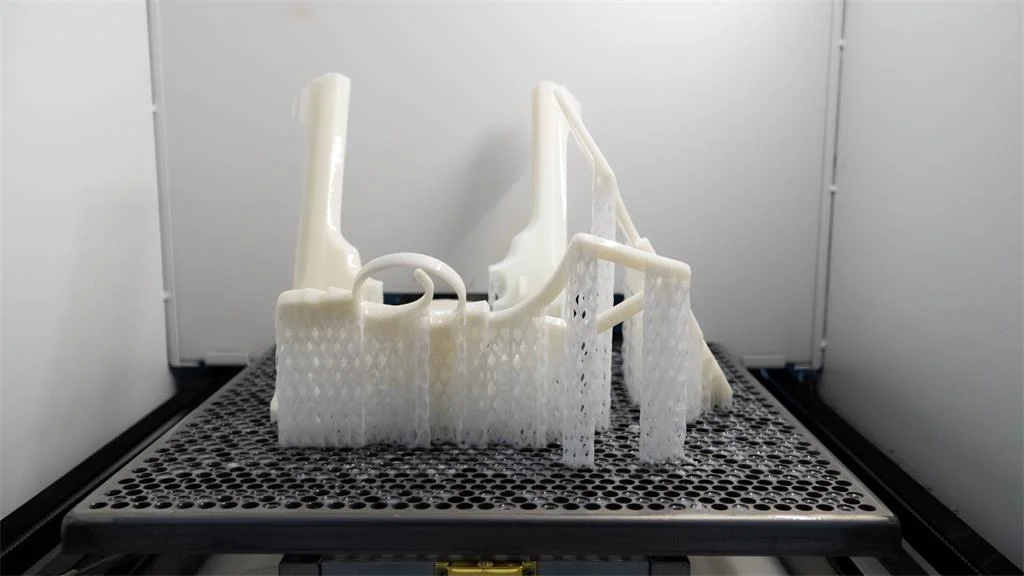

SLA 3D printing is used in a variety of applications, including medical devices and consumer electronics.SLA 3D printing uses light-sensitive liquid resin to create objects.This creates a thin layer resin which is then cured with a UV laser.This produces a very precise part.To remove any excess resin, the parts are cleaned using an isopropyl alcohol bath.

An ultraviolet oven can be used to enhance the mechanical properties of SLA components.SLA is a great option if you are looking for a 3D printer that costs less.

Advanced users might have their own designs and specifications for SLA parts.Advanced users might have hollowed out parts in order to save material.An SLA printer will start printing after a quick confirmation.It is fully automated.It can be left to you or your team to do the work.

Resin tank systems also automatically refill the material so that you don’t have to monitor it.

For added convenience, Formlabs also offers an online dashboard that allows you to manage your printers, materials and teams.

The SLA 3D Printer is more professional than other 3D Printing Technologies.The printer can produce parts with precise detail and high-quality surface finishes.This method does require post-processing so be sure to allow for some space when designing.You should also be familiar with post-processing as it will impact the final appearance of your 3D object.After you have completed the design, you can print it to verify its functionality.

An SLA 3D printer costs more than a fused deposition modeling machine.

Stereolithography resin is cheap, and the remaining support structures and residues are thrown away without much cost impact

Stereolithography 3D printing uses light to cure liquid resin.

Resin is a thermoset plastic that is kept in the resin tank of the printer.

After the resin has been cured by a UV or laser it can be used to create a 3D model.SLA printers are available in two types: top-down or bottom-up.

Industries use top-down configurations, while desktop SLA printers often use bottom-up configurations.

An SLA printer’s most popular orientation is either top-down, or bottom-up.

Each orientation has its advantages and disadvantages.

Bottom-up is simpler to produce, but it is smaller in size.unless choose ZONGHENG3D SLA series you can also building large size mould.

You must also pay attention to the weight when building upside-down models.Heavy prints can easily fall off the platform.Top-down SLA printers, on the other hand, have no weight restrictions but are more costly.