3D printing technology has advanced rapidly in recent years, with two of the most popular methods being stereolithography (SLA) and selective laser sintering (SLS). Both SLA and SLS produce high-quality 3D printed parts, but they utilize different processes. When deciding which 3D printing method to use for a project, the costs often play a major role. In this guide, we’ll break down the typical costs of SLA vs SLS and look at the factors that impact pricing to help you determine which offers the best value.

An Overview of SLA 3D Printing

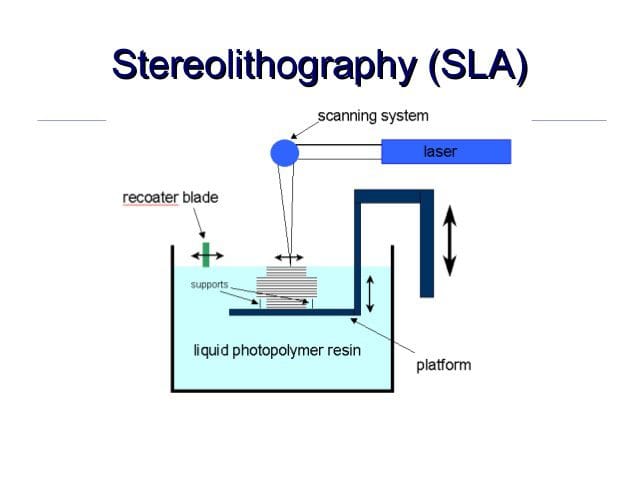

SLA 3D printing, also known as stereolithography or resin 3D printing, is an additive manufacturing process that uses photopolymer resin and an ultraviolet laser to build parts layer-by-layer. In SLA printing, the laser beam traces the cross-section of the part onto the surface of the liquid resin. This causes the resin to solidify, forming one layer of the part.

Once a layer is finished, the build platform raises and more resin coats the previous layer. The laser then traces and cures the next layer on top of the previous one. This process repeats until the full 3D object has been formed within the resin vat. Parts are then rinsed to remove excess liquid resin and may require additional post-curing and surface finishing.

Some key benefits of SLA 3D printing include:

- High accuracy and detail down to 25-50 microns

- Smooth surface finish

- Ideal for complex geometries and small parts

- Variety of engineering-grade and specialty resins available

Overall, SLA produces accurate prints with excellent surface finish and intricate details. It is commonly used for prototyping, dental and medical applications, jewelry, and more.

How SLS 3D Printing Works

Selective laser sintering, or direct metal laser sintering (DMLS) for metal materials, is another popular additive manufacturing process. SLS uses a high-power laser to fuse small particles of polymer powder or metal powders together layer-by-layer to form a 3D object.

The SLS printing process consists of the following key steps:

- A thin layer of powder is spread evenly across the build platform using a recoater blade.

- The laser selectively fuses areas of the powder bed corresponding to the part cross-section for that layer.

- The build platform lowers by one layer thickness and the recoater blade spreads new powder over the surface.

- Steps 2-3 repeat until the complete part has been fabricated inside the powder bed.

Excess powder is removed to reveal the finished part

SLS does not require supports and allows for complex geometries. It is commonly used to print functional prototypes, end-use production parts, and low-to-medium volume manufacturing. Key benefits include good mechanical properties and versatility across plastics, metals, ceramics, and alloy materials.

Cost Factors for SLA 3D Printing

When estimating costs for an SLA 3D printing project, there are several important factors to consider:

1. Resin Cost

The photopolymer resin is one of the primary contributors to material costs in SLA printing. Resin prices range widely based on the material properties, print quality, and brand.

Basic, non-engineered resins can cost $50-100 per liter. Engineering resins with enhanced mechanical properties generally range from $100-300 per liter. Some advanced resins can cost up to $500+ per liter.

More expensive resins tend to produce stronger parts with improved heat resistance, tensile strength, and accuracy.

2. Printer Operating Costs

Operating costs include electricity usage, resin tank replacement, laser maintenance, and other upkeep. These costs may add an additional $2-15 per hour of print time. Larger industrial SLA printers use more energy and resin.

3. Labor Costs

The operator’s time for printing, monitoring the build, finishing parts, and printer maintenance should be included in cost estimates. Labor may range from $20-150 per hour based on staff skills and experience.

4. Print Time

Longer print times will increase resin and operating costs. Print time depends on factors like the part size, orientation, layer thickness, and printer model. SLA printers typically have build speeds of 1-2 inches per hour vertically.

5. Post-Processing

Additional labor and materials are often needed for post-processing steps like support removal, washing, and curing. This can add several dollars per part depending on the methods used.

6. Printer Purchase Cost

The upfront SLA printer investment ranges widely from $3,000 for a basic desktop unit up to $500,000+ for large production printers. Amortizing the printer purchase cost over expected usage must be accounted for.

What Influences SLS 3D Printing Costs?

For SLS 3D printing, here are some of the main factors that impact overall costs:

1. Material Expenses

SLS materials are pricier than typical filament. Polymer powders range from $100-200 per kilogram. Metal powders for DMLS can cost $250-1000+ per kilogram depending on the alloy. Material choices heavily influence finished part costs.

2. Initial Printer Investment

Industrial SLS printers start around $150,000, with higher-end machines easily over $500,000. The initial capital investment is very high compared to other 3D printing processes. This equipment cost needs to be spread over expected usage volume.

——Adding to that, ZONGHENG3D has recently developed an industrial-grade SLS 3D printer, which is comparable to similar products currently on the market. It is now being sold at a competitive price of $69,800. SLS – 3540 PRO

3. Energy Consumption

The laser sintering process consumes significant electricity. Larger build volumes require more energy to heat and fuse material. Operating costs are estimated around $10-30 per hour depending on printer size.

4. Labor Costs

A trained SLS technician is needed to operate the printer, finish parts, and handle maintenance. Typical range is $25-100 per hour. Additional labor may be needed for designing supports and orienting parts.

5. Machine Capacity

How much of the build chamber volume is used for each print determines material efficiency. Printing multiple parts in each cycle improves economy of scale. Larger machines offer lower costs per part.

6. Part Density

SLS allows users to specify interior densities from 20-100%. Low-density prints use less powder, reducing per-part material expenses. However, lower densities have weaker mechanical properties.

7. Size and Geometry

Larger and more complex parts take longer to print. This positively correlates with material, energy, and labor costs. Simple or miniature parts can be economical.

Cost Comparison of SLA vs SLS Printing

While exact costs always depend on the specific application, some general comparisons can be made between SLA and SLS printing costs:

- SLA printers have a lower upfront equipment investment, ranging from desktop models under $3,000 up to $500,000 for industrial printers. SLS equipment starts around $150,000 and can exceed $1 million.

- SLA resins currently range from $50-500 per liter. SLS materials run $100-1000+ per kilogram. SLS tends to have higher material costs overall.

- SLA has lower operating costs around $2-15 per hour. SLS operating costs are estimated at $10-30 per hour due to higher energy use.

- Both technologies have comparable costs for labor, post-processing, and printer maintenance. However, SLS parts often require more support removal.

- Smaller parts favor SLA, which has higher accuracy and detail resolution. For larger volumes, SLS benefits from economies of scale.

- SLA can produce fine details down to 0.025mm, while SLS is limited to about 0.08mm minimum feature size.

- SLS offers material versatility, but SLA has a wider range of specialty resins available.

For very low volume production like prototypes, SLA generally offers the most cost-effective and detailed prints. As volumes scale, SLS becomes more competitive and can be cheaper for mid-to-high production runs. However, SLA printers are improving build speeds and capacities, which may impact the crossover point in the future.

Tips for Reducing SLA and SLS 3D Printing Costs

Here are some ways to help minimize costs for both SLA and SLS printing:

- Optimize part orientation to minimize supports and printing time. This saves on resin/powder, energy use, and labor.

- Use lower resin layer thicknesses or SLS densities only where needed. Use higher settings in non-critical areas.

- For SLS, maximize build chamber space by printing multiple parts per cycle.

- Look at material properties carefully and match them closely to application needs rather than over-specifying.

- Consider finishing parts after printing rather than using expensive specialty materials to achieve surface requirements.

- Look for 3D printing service providers that offer economy and value resin or powder options.

- Negotiate discounted rates for higher volume orders from material suppliers and printing services.

- Take advantage of any printer idle time through efficient project scheduling and batching.

Key Takeaways on SLA and SLS Costs

To recap, here are some of the essentials on comparing SLA vs SLS printing costs:

- SLA printers have lower upfront equipment costs along with very high accuracy and surface finish. This makes SLA ideal for low-volume prototyping applications.

- SLS has higher initial printer investments but becomes more cost-effective at higher production volumes due to material efficiency and minimal post-processing.

- Resin costs for SLA range from $50-500 per liter. SLS powder prices run from $100-1000+ per kilogram.

- SLA operating costs estimated around $2-15 per hour. SLS operating costs range from $10-30 per hour.

- Optimize prints to reduce supports, materials, and print time. Batch similar jobs.

- Consider the tradeoffs between specialty materials versus secondary finishing operations.

- Look at service providers for economy resin and powder options. Negotiate discounts on higher volumes.

Overall, SLA and SLS both offer high-quality 3D printing capabilities. Considering the detailed cost factors above will help you determine the most economical and beneficial option for your specific application needs. Analyzing part geometries, volumes, and material requirements will provide the data needed to make the right decision between SLA vs SLS 3D printing.

The Future of SLA and SLS Costs

3D printing technology continues advancing rapidly. Here are some developments that can impact future SLA and SLS costs:

- New higher-speed SLA printers can reduce per-part labor and operating costs. This may make SLA even more competitive for production applications.

- Expanded SLA material options, including ceramic and composite resins, provide more choices to optimize cost and mechanical properties.

- Competition is driving down prices on industrial SLS equipment and economy powder materials, improving access.

- Integrated SLS systems with powder handling and recycling features improve material efficiency.

- As SLS printer sizes increase, larger build volumes will improve economy of scale.

- Automated post-processing systems for SLA and SLS can reduce labor costs and throughput times.

- Design software enhancements allow more efficient print nesting, build orientation, and hollowing/infill optimization to save costs.

The rapid pace of 3D printing developments will continue expanding capabilities while driving costs down. This makes both SLA and SLS technology extremely promising for cost-effective short-run manufacturing.

Determining if SLA or SLS 3D printing is more cost-effective depends on factors like print volume, part size, complexity, accuracy needs, and material properties. SLA typically offers more economical low-volume prototyping while SLS scales better to higher production volumes.

Carefully analyzing the costs factors outlined in this guide will help identify the most affordable option for your specific application. Both SLA and SLS processes are advancing rapidly to expand capabilities and reduce costs. The ongoing improvements will make these 3D printing technologies even more compelling alternatives for short-run manufacturing across a widening range of industries.