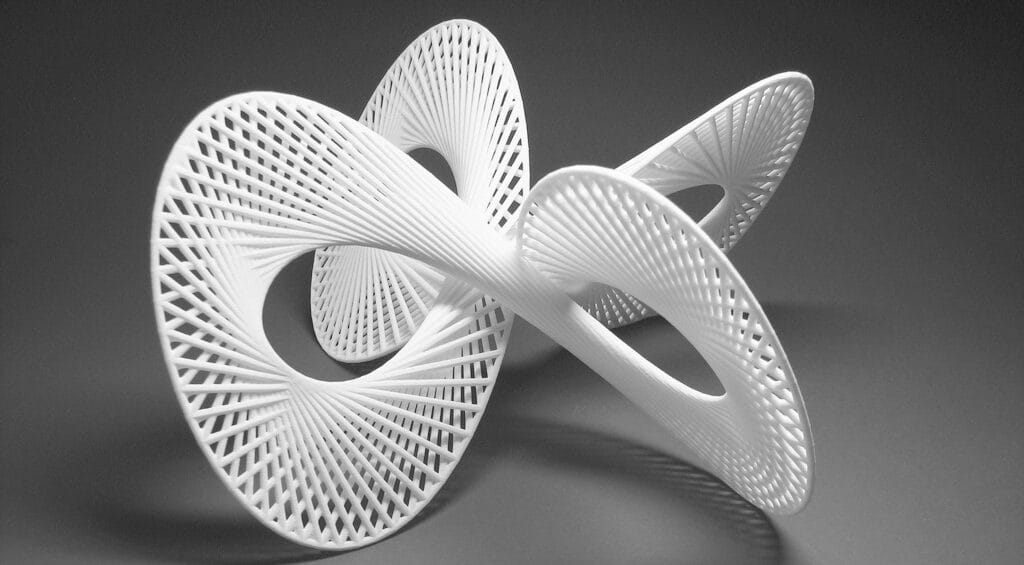

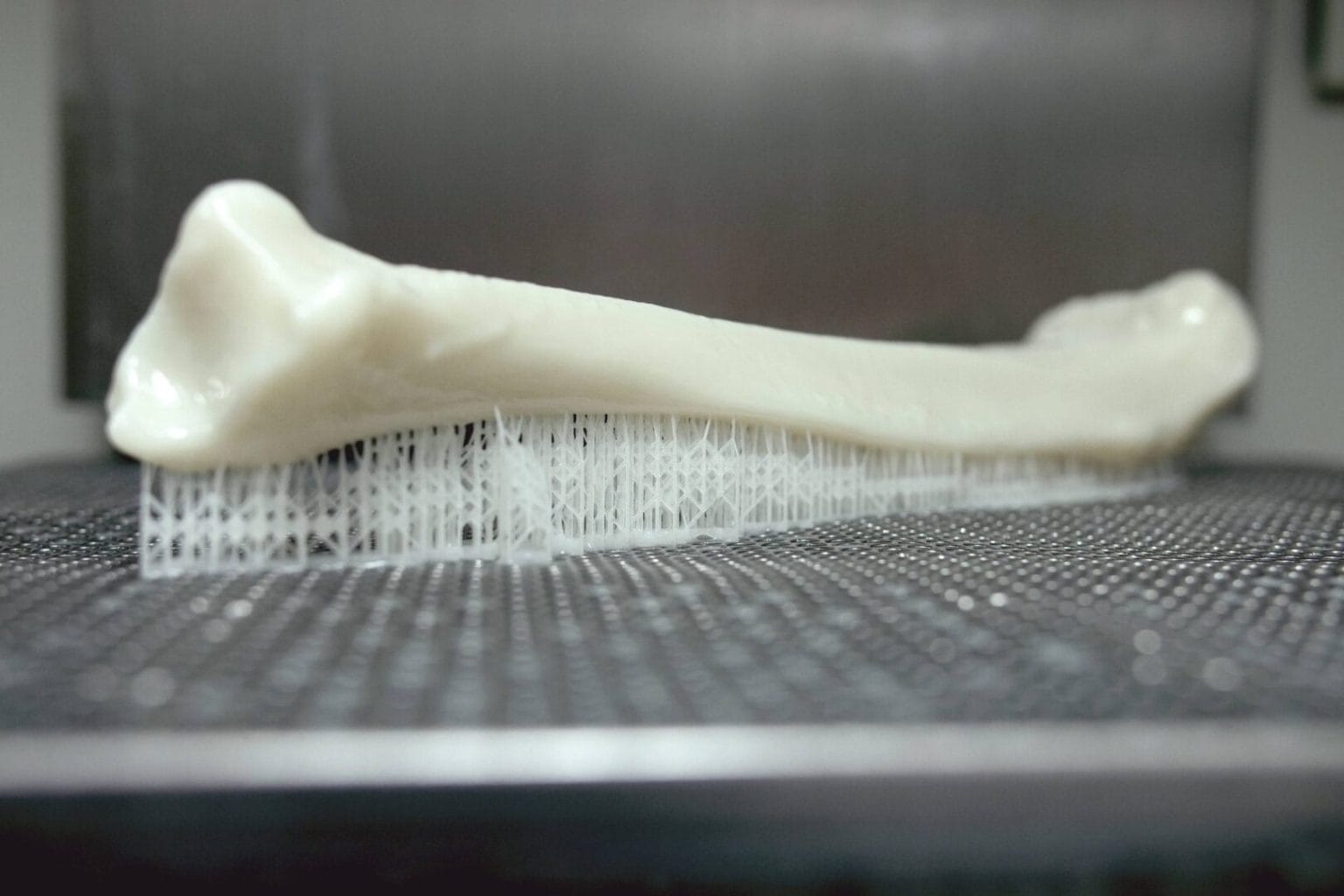

SLA (Stereolithography) 3D printing technology is often considered one of the best methods for producing high-quality, intricate 3D prints, thanks to its high resolution and ability to create incredibly detailed models. However, as with any manufacturing process, there are costs associated with SLA 3D printing that must be understood before committing to the technology.

In this article, we will take a closer look at the various costs that come with SLA 3D printing, and how to calculate them to ensure that your project stays within budget.

The Costs of SLA 3D Printing

1. Printer Cost

The first and most apparent cost of SLA 3D printing is the printer itself. While there are many different models and brands available on the market, most high-quality SLA 3D printers range from $3,000 to $10,000. This initial investment is something to consider when deciding whether SLA 3D printing is the right technology for your project.

2. Resin Cost

Another significant cost of SLA 3D printing is the resin used to create the models. Resin can range in price from $50 to $400 per liter, depending on the quality and specifications of the material. Additionally, different colors and finishes may increase the cost of the resin even further.

3. Maintenance and Repair Costs

Like any piece of machinery, SLA 3D printers require regular maintenance to stay in top condition. This may include replacing parts or repairing components, which can add to the overall cost of using the technology. It is essential to factor in these ongoing maintenance expenses when budgeting for SLA 3D printing.

4. Labor Costs

While 3D printing has become incredibly automated over the years, there is still a significant amount of labor involved in the process, from designing the model to post-processing the final product. These labor costs should be factored into the overall cost of a project, as they can significantly impact the final price of the 3D printed object.

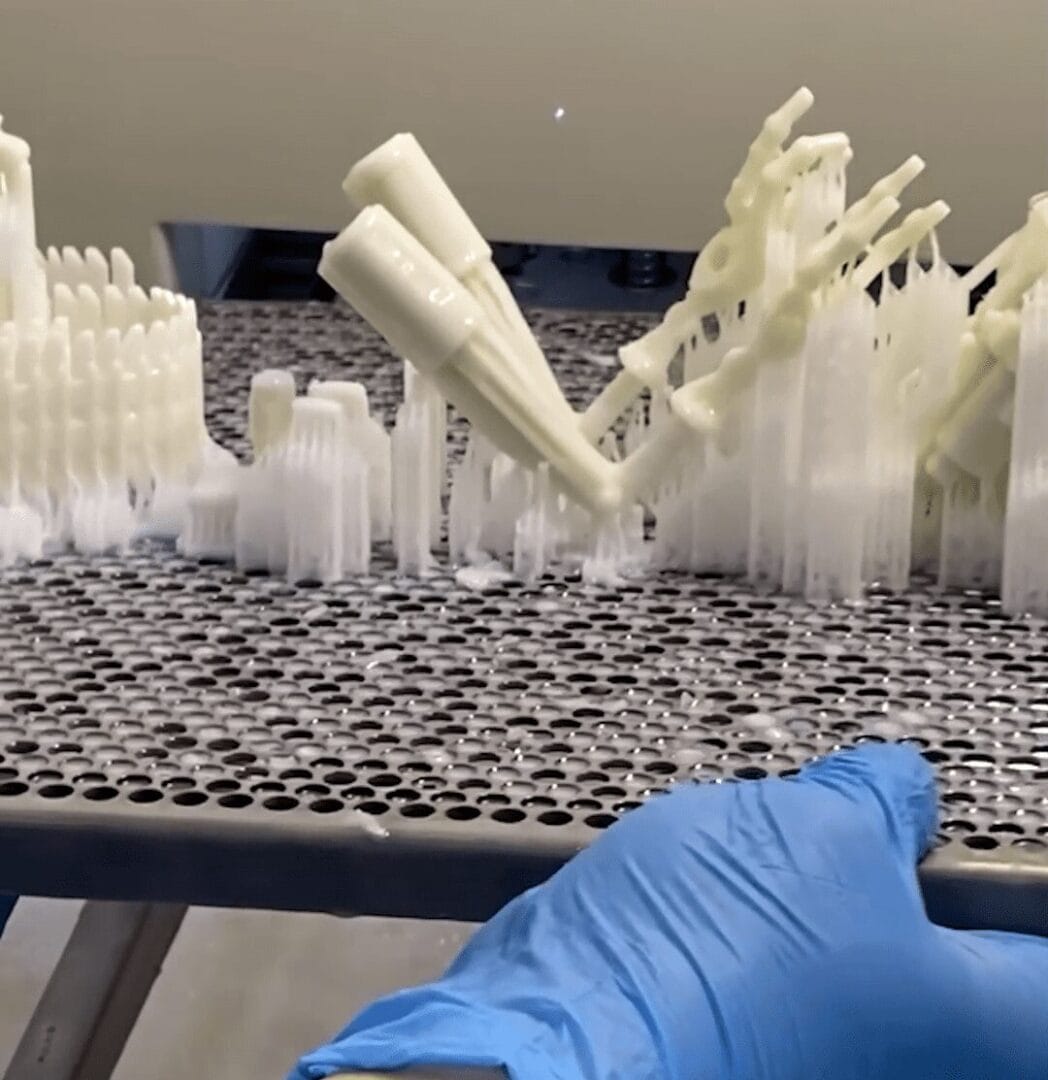

5. Post-Processing Costs

Post-processing is an essential step in the 3D printing process that involves sanding, polishing, and other finishing touches to ensure that the final product meets the desired specifications. While some post-processing can be done in-house, more advanced techniques may require outsourcing to a professional service, which can add to the overall cost of the project.

Calculating the Total Cost of SLA 3D Printing

To calculate the total cost of SLA 3D printing a project, it is essential to consider all of the factors above and determine the costs associated with each one. This can be done by estimating the amount of resin required, factoring in maintenance and repair costs, and considering the amount of labor required at each stage of the process.

Once these costs have been determined, they can be added together to create a total cost estimate for the project. This estimate can then be compared to the budget to ensure that the project is financially viable and to make any necessary adjustments to stay within the allotted budget.

While SLA 3D printing technology offers numerous benefits, it is essential to understand the costs associated with the technology before committing to it for a project. By considering factors such as printer cost, resin cost, maintenance and repair costs, labor costs, and post-processing costs, it is possible to create an accurate estimate of the total cost of SLA 3D printing. With careful planning, SLA 3D printing can be a cost-effective way to produce high-quality, detailed 3D prints.