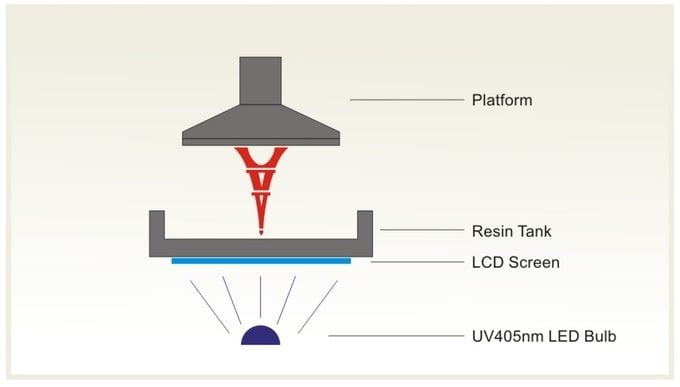

Over the years, 3D printers are no longer high- tech products, but deep into the daily lives of ordinary people. Moreover, 3D printing technology can be used in more and more fields, and photocurable 3D printing technology has also emerged, and the most common is DLP, SLA, LCD and other photocurable technology. But many friends do not know which technology for their own, today we will discuss.

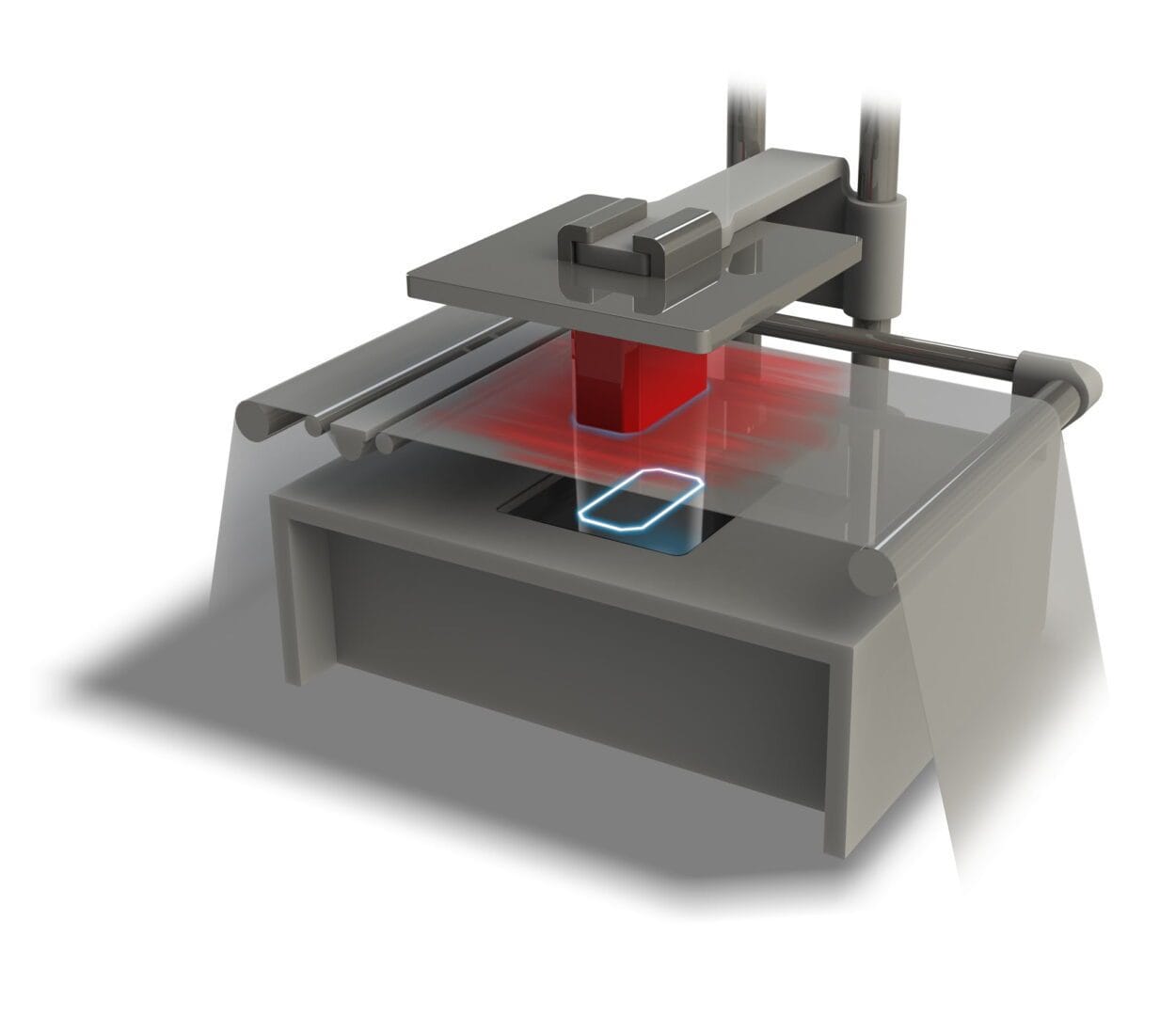

The DLP’s Digital Light Processing uses an ultraviolet projector as a light source, which works by controlling the light projected through the original digital microscope (DMD). One layer at a time, one layer at a time. So DLP is faster than SLA in speed. So, the printed object rises at the same time, and the projector projects a layer of 3D model shapes onto the resin, which is then printed over and over again and the object is printed. It is important to note that objects that are printed are printed backwards, unlike FDM printing. Because DLP uses a projector to project each layer of images onto a printing platform, each layer of images is made up of a square called a pixel.

Generally speaking, it is industrial level to use DLP technology, but now there is also a DLP technology desktop products, small size, easy to use, interested friends can also consider buying DIY to make the desired model.

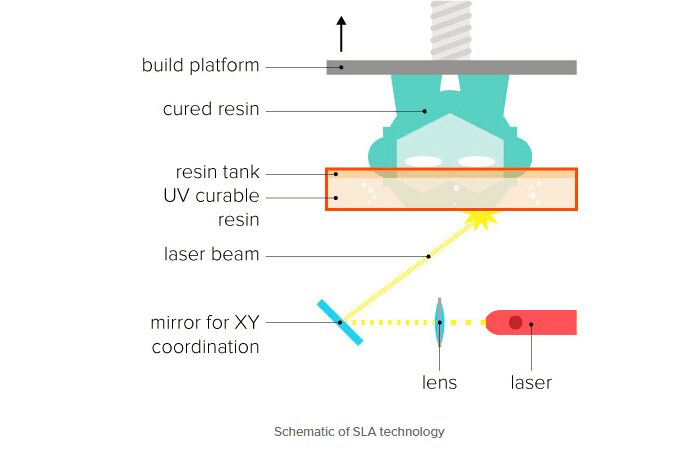

As for SLA 3D printing technology, the technology does not use light projectors, but through the laser liquid photosensitive resin into the liquid photosensitive resin, so that a layer of photosensitive resin curing, ultimately forming the overall shape. SLA light curing is the laser shot into the liquid resin surface to form a curing layer. Similar to DLP printers, SLA light curing is similar to DLP printers and includes elevated printing platforms.

After the first layer of photosensitive resin solidifies, the platform adds a distance and then prints the second layer with a laser. By analogy, layer by layer printing, the final form of complete graphics. Another container contains liquid photosensitive resin. SLAs take longer, but have higher accuracy and print success rates. Compared with printable area, DLP is projected, so the printing area of SLA is smaller.